Broom wooden handle bottom cutting equipment

A technology of cutting equipment and wooden handle, applied in the field of cutting equipment at the bottom of wooden handle of brooms, can solve the problems of scattered wood chips, high work intensity, inconvenient cleaning and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

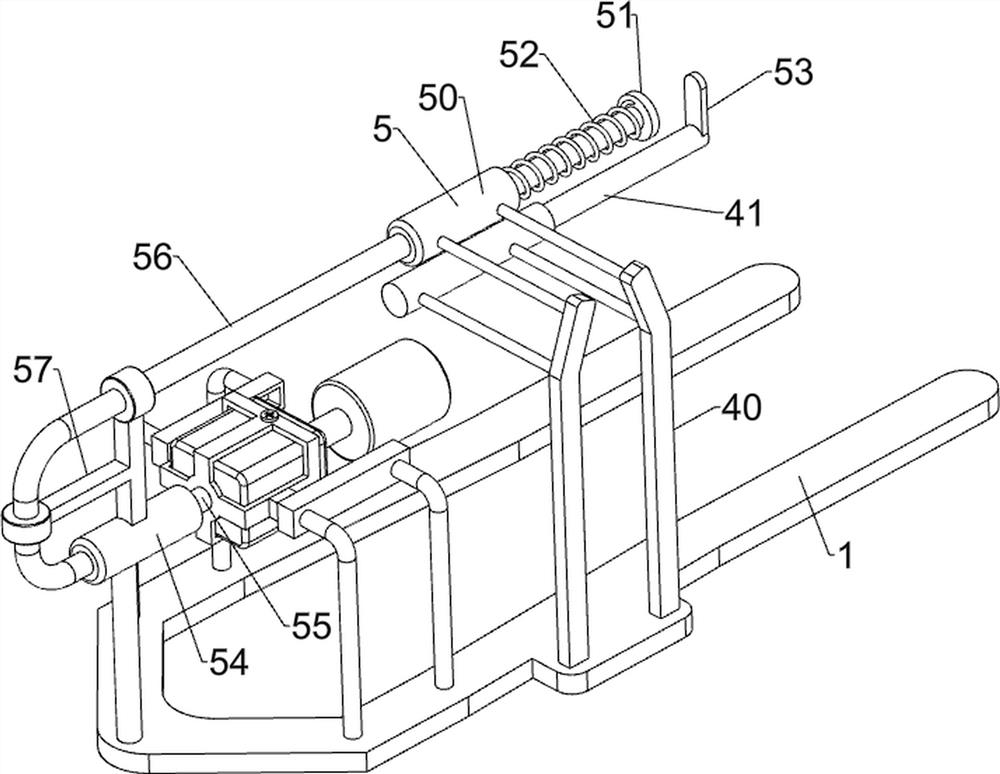

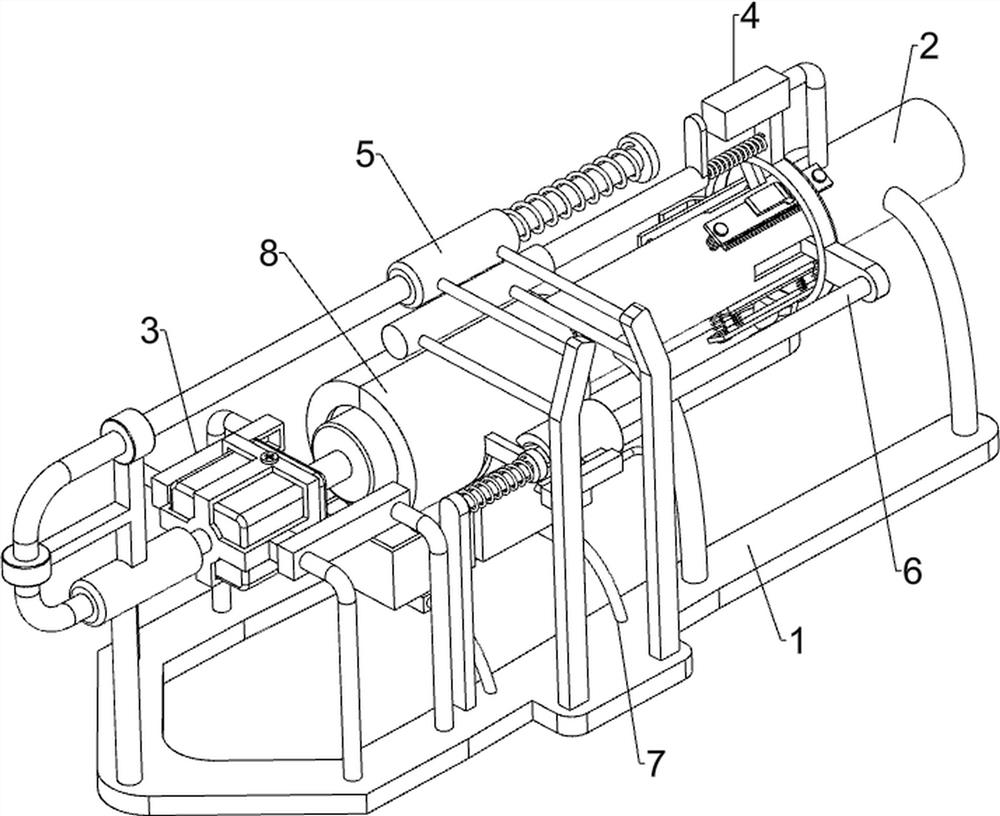

[0029] A broom handle bottom cutting device such as figure 1 As shown, it includes a base 1 , a placement mechanism 2 and a cutting mechanism 3 , the top right side of the base 1 is provided with the placement mechanism 2 , and the top left side of the base 1 is provided with the cutting mechanism 3 .

[0030] When it is necessary to cut the bottom of the wooden handle, first place the wooden handle in the placing mechanism 2, manually clamp the wooden handle through the parts of the placing mechanism 2, then open the cutting mechanism 3, and manually push the parts of the cutting mechanism 3 to the right Move and cut the bottom of the wooden handle. After cutting, loosen the parts of the placement mechanism 2, no longer clamp the wooden handle, take out the wooden handle, and close the cutting mechanism 3.

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the placement mechanism 2 includes a placement cylinder 20, a clamping block 21, a slide bar 22, a slide plate 23, a first spring 24, and a second spring 25, and the placement cylinder 20 is arranged between the front and rear of the top right side of the base 1, and the placement cylinder The middle part of 20 is provided with a clamping block 21 which is evenly slidable in the circumferential direction, and the placement tube 20 is symmetrically provided with slide bars 22. The number of slide bars 22 is 8, and the slide bars 22 are respectively located on both sides of the clamp block 21 at the same horizontal level. A slide plate 23 is provided in a sliding manner between the slide bars 22, and a first spring 24 is connected between the left and right sides of the slide plate 23 and the placement tube 20, and the first spring 24 is sleeved on the first slide bar 22, and the...

Embodiment 3

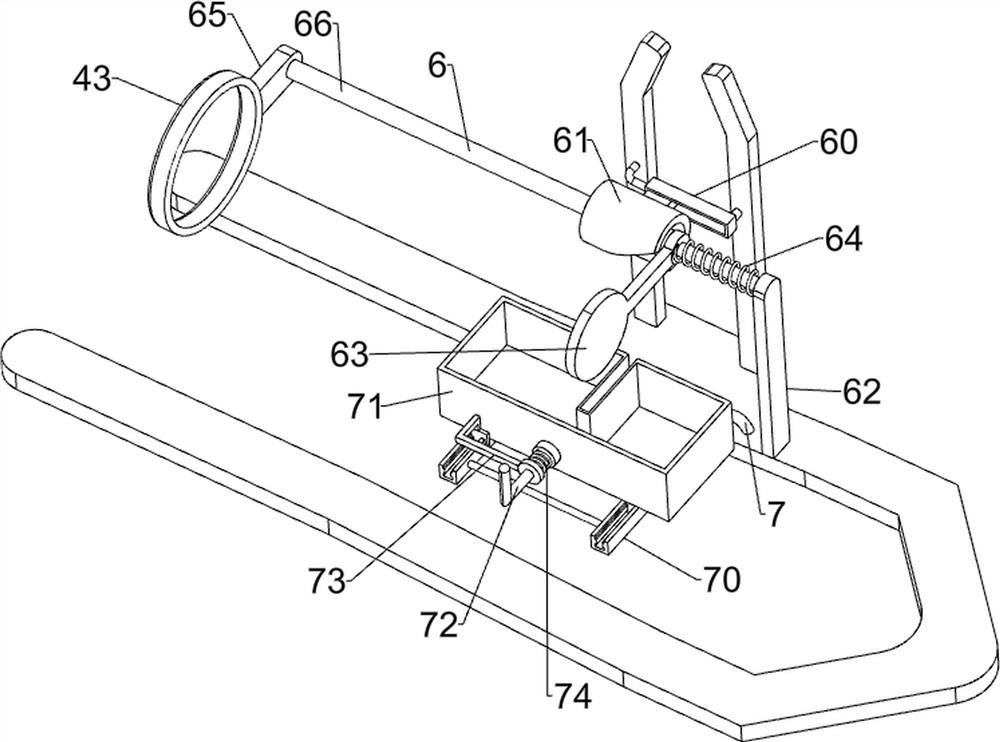

[0037] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, an automatic clamping assembly 4 is also included, and the automatic clamping assembly 4 includes a mounting plate 40, an electric push rod 41, a wedge block 42, a sliding ring 43, a sliding rail 44, a sliding block 45 and a third spring 46, the base 1. A mounting plate 40 is symmetrically arranged in the middle part of the front side of the top, an electric push rod 41 is provided between the upper part of the rear side of the mounting plate 40, a wedge-shaped block 42 is provided in the middle part of the outer side of the slide plate 23, and a sliding ring 43 is provided in the middle part of the storage tube 20 for sliding, Sliding ring 43 cooperates with wedge-shaped block 42, is provided with sliding rail 44 on the upper part of placing tube 20 right sides, and sliding type is provided with slider 45 on sliding rail 44, and the bottom of sliding block 45 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com