Quick-cooling forming equipment for PVC pipeline production

A technology of rapid cooling and forming equipment, applied in the field of PVC pipe production, can solve the problems of unsuitable installation, difficult maintenance, long cooling device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

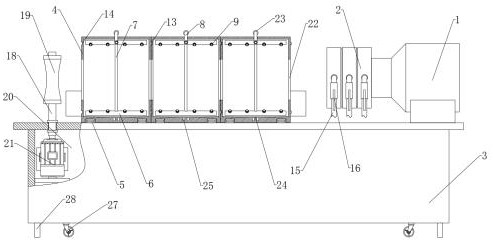

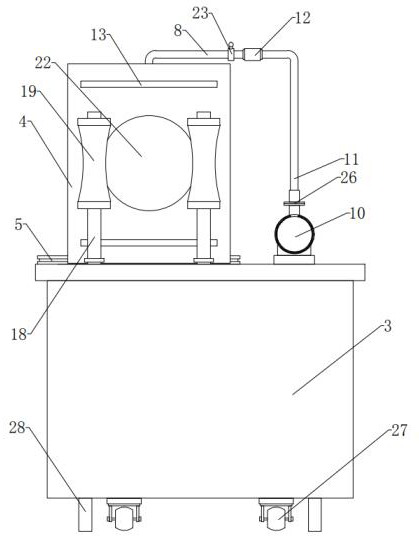

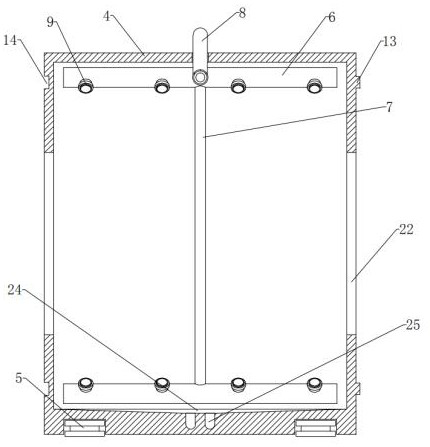

[0030] Embodiment: according to specification Figure 1-5 , this case is a molding equipment for PVC pipe production that can be cooled rapidly, including an extruder 1, a molding die 2, a processing table 3, several cooling sections 4 and output components, and the molding die 2 is installed at the end of the extruder 1, The processing table 3 is installed on one side of the extruder 1, and several cooling sections 4 are connected to each other and correspond to the molding die 2. The output assembly is installed on the processing table 3, and is located on one side of the several cooling sections 4 and one side of the molding die 2. Correspondingly, the molding die 2 is provided with a pressurized cooling cycle structure, and several cooling sections 4 are respectively provided with several single-stage cooling structures. The basis is that the pressurized cooling cycle structure on the forming mold 2 adopts a pressurized water inlet cycle, which can increase the cooling rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com