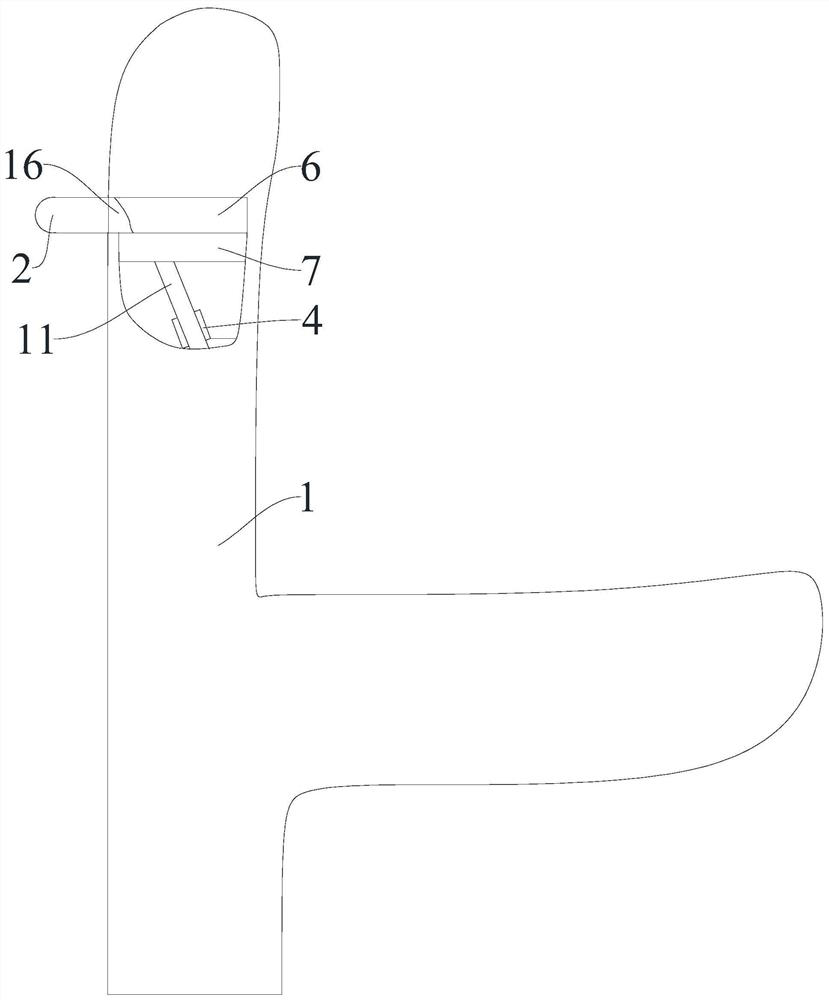

Telescopic turnover type back safety armrest for bus

A flip-type, bus technology, applied to vehicle parts, special positions of vehicles, and sanitary equipment for toilets, etc., can solve problems such as easy cleaning dead ends, germ growth, cross-infection, etc., to improve safety and anti-fouling Performance, ease of installation, improved stability and support effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

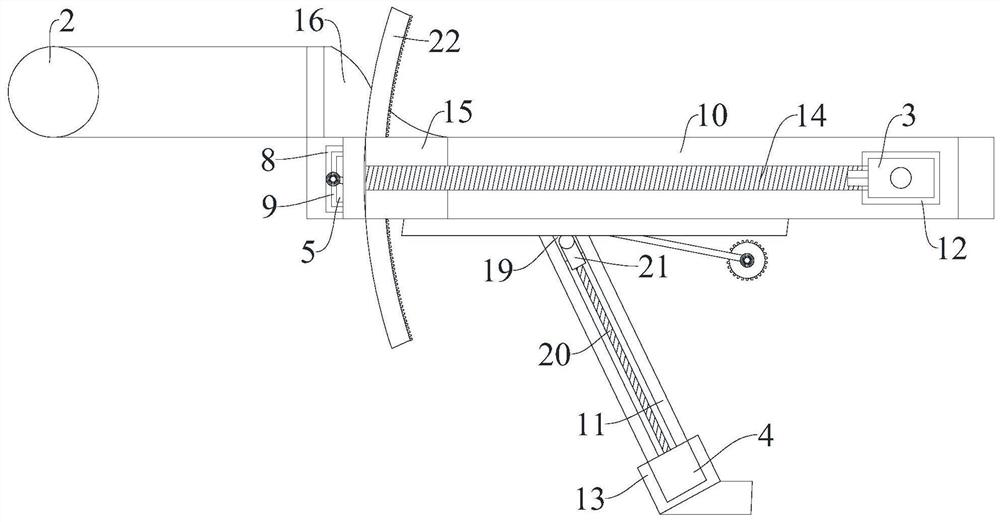

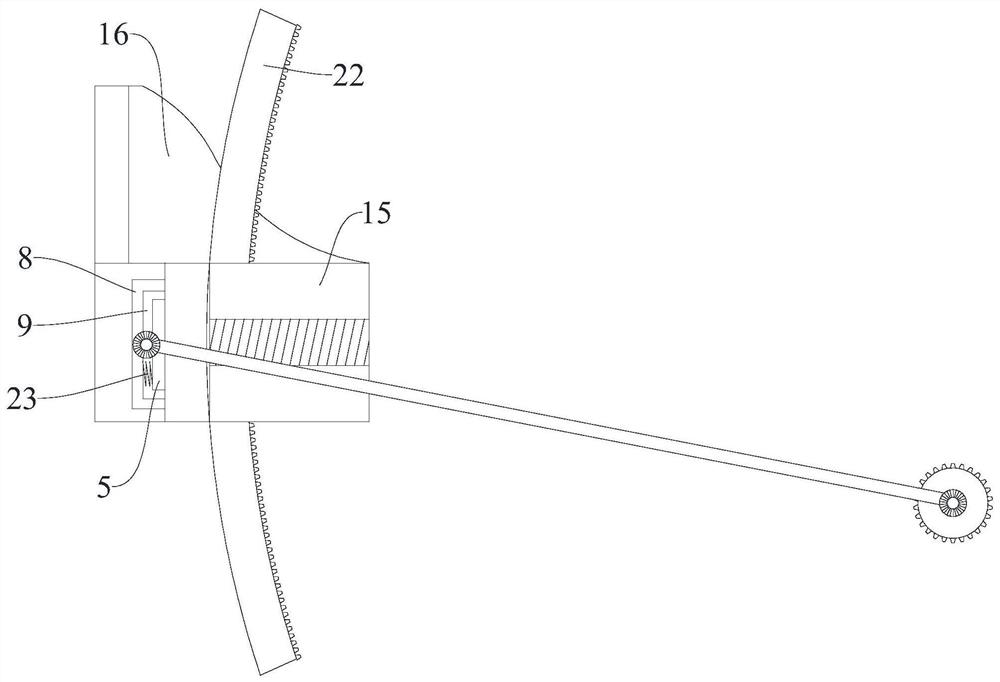

[0023] Embodiment: The drive motor 3 is controlled by the pressure-sensitive switch on the rear seat. When people leave the rear row, the drive motor 3 and the ultraviolet sterilizing lamp 5 start, which drives the internal linkage adjustment bracket to shrink. When the internal linkage adjustment bracket moves to the motor Mounting frame 12 position, fix pressure control switch on the outside of motor mounting frame 12, start adjustment motor 4, close drive motor 3; Put the push switch on the inner top of the guide rail 11, the drive motor 3 starts, the ultraviolet sterilizing lamp 5 and the adjustment motor 4 close, and the drive motor 3 controls the internal linkage adjustment bracket to extend to the outermost side and then close.

[0024] Adjustment through holes are provided on both sides of the internal adjustment frame 7 to facilitate the adjustment of the installation position. At the same time, a strip support plate is fixed below the lateral connection bracket 16 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com