Quick-curing ink binder and preparation method thereof

A technology of ink binder and ink oil, applied in ink, household utensils, applications, etc., can solve the problems of printing stickiness, slow ink fixation speed, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

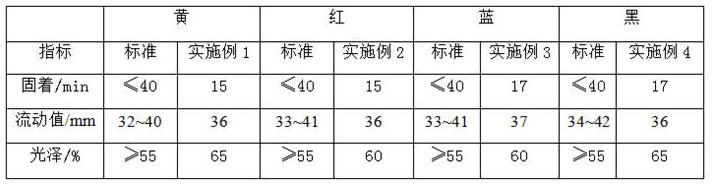

Examples

Embodiment 1

[0022] Fast solid ink is prepared according to the following steps:

[0023] (1) Preparation of fast-curing ink binder

[0024] Weigh the components in the fast-curing ink binder formula in parts by mass: 45 parts of resin, 30 parts of vegetable oil, 25 parts of ink oil and 1 part of aluminum liquid; wherein, the resin is 25 parts of rosin modified phenolic resin, linseed oil 15 parts of modified alkyd resin and 5 parts of modified alkyd resin of soybean oil; the vegetable oil is 20 parts of linseed oil and 10 parts of soybean oil; the ink oil is mineral oil with a distillation range of 260 °C, and the aluminum liquid is vegetable oil. The score is 20%.

[0025] According to the formula dosage of fast solid ink binder:

[0026] Step 1. Melting the resin: Put vegetable oil and 20 parts of ink oil into the reaction kettle, stir and heat to 200°C, keep warm for 60min, the stirring speed is 90r / min, and the heating speed is 40°C / h;

[0027] Step 2. Dispersion of aluminum liquid...

Embodiment 2

[0032] Fast solid ink is prepared according to the following steps:

[0033] (1) Preparation of fast-curing ink binder

[0034] Weigh the components in the fast-curing ink binder formula in parts by mass: 43 parts of resin, 30 parts of vegetable oil, 27 parts of ink oil and 1 part of aluminum liquid; wherein, the resin is 23 parts of rosin modified phenolic resin, linseed oil 15 parts of modified alkyd resin and 5 parts of modified alkyd resin of soybean oil; the vegetable oil is 20 parts of linseed oil and 10 parts of soybean oil; the ink oil is mineral oil with a distillation range of 280 °C, and the aluminum liquid is vegetable oil. The score is 15%.

[0035] According to the formula dosage of fast solid ink binder:

[0036] Step 1. Melting the resin: Put vegetable oil and 17 parts of ink oil into the reaction kettle, stir and heat to 200°C, keep warm for 60min, the stirring speed is 90r / min, and the heating speed is 40°C / h;

[0037] Step 2. Dispersion of aluminum liquid...

Embodiment 3

[0042] Fast solid ink is prepared according to the following steps:

[0043] (1) Preparation of fast-curing ink binder

[0044] Weigh the components in the fast-curing ink binder formula in parts by mass: 40 parts of resin, 30 parts of vegetable oil, 30 parts of ink oil and 1 part of aluminum liquid; wherein, the resin is 20 parts of rosin modified phenolic resin, linseed oil 15 parts of modified alkyd resin and 5 parts of modified alkyd resin of soybean oil; the vegetable oil is 20 parts of linseed oil and 10 parts of soybean oil; the ink oil is mineral oil with a distillation range of 300 °C, and the aluminum liquid is vegetable oil. The score is 10%.

[0045] According to the formula dosage of fast solid ink binder:

[0046] Step 1. Melting the resin: Put vegetable oil and 20 parts of ink oil into the reaction kettle, stir and heat to 200°C, keep warm for 60min, the stirring speed is 90r / min, and the heating speed is 40°C / h;

[0047] Step 2. Dispersion of aluminum liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com