Method for preventing and treating ash blocking of tail flue gas channel of double-tangent-circle combustion boiler

A technology of flue gas channel and double tangent circle, which is applied in the direction of combustion method, control combustion, lighting and heating equipment, etc., can solve the problems of research and prevention of ash accumulation in the tail channel, which have not been reported, and achieve simple implementation and low cost , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will further illustrate the present invention through specific examples, but it is not intended to limit the protection scope of the present invention. Those skilled in the art can make improvements to the preparation method and the equipment used within the scope of the claims, and these improvements should also be considered as the protection scope of the present invention. Therefore, the protection scope of the patent for the present invention should be based on the appended claims.

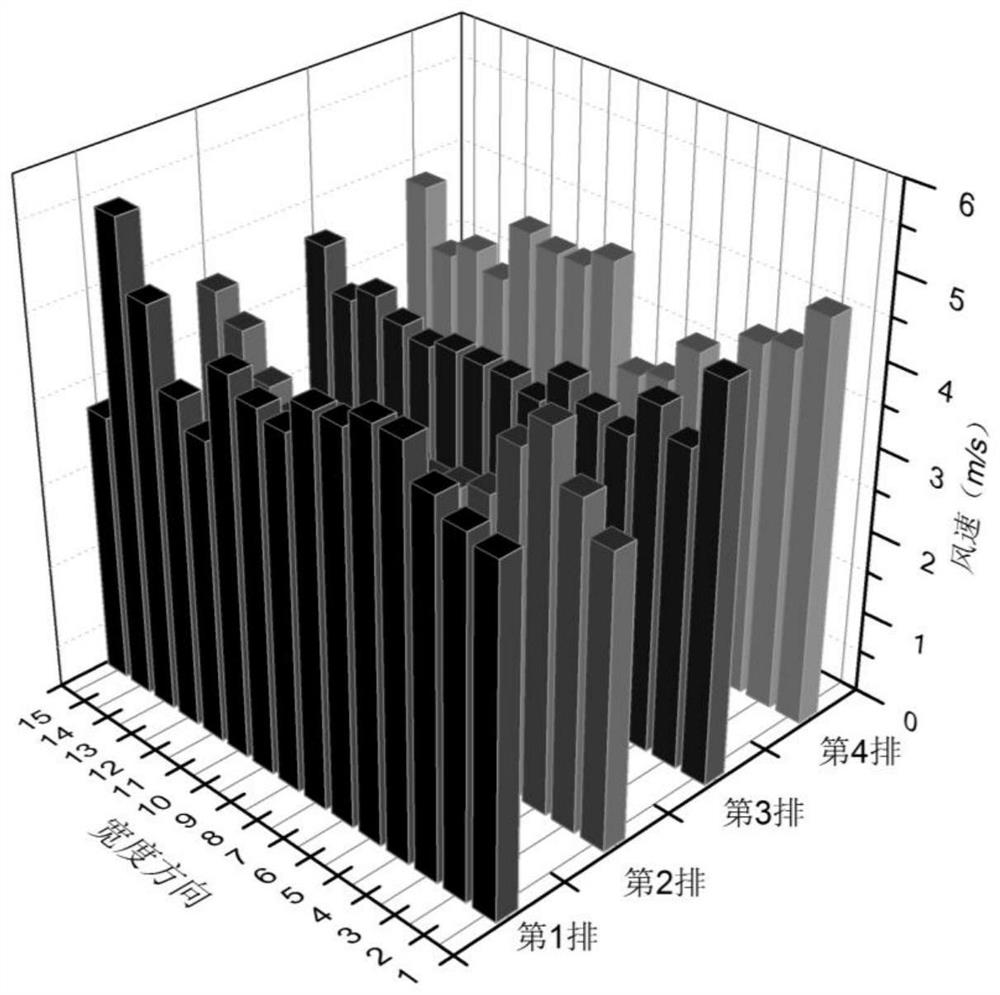

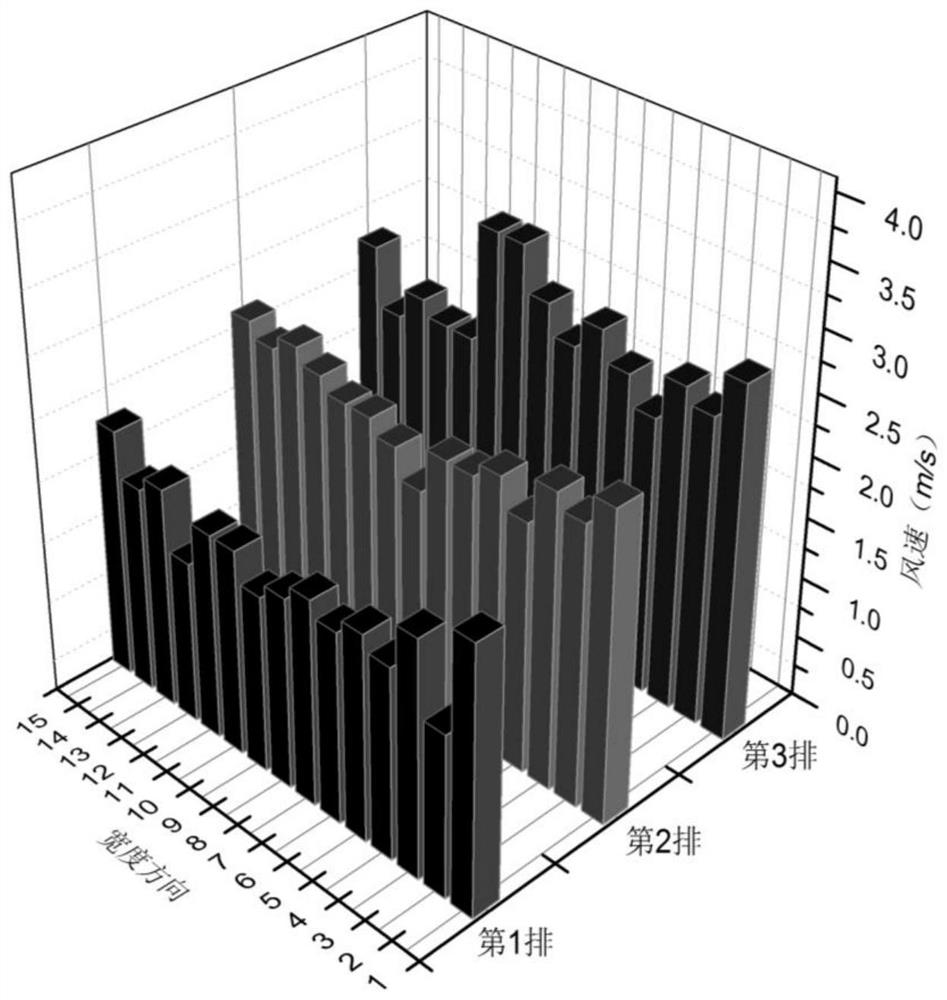

[0037] Boiler No. 1 in a power plant adopts a double tangential circle combustion method. Corner burners #1~#4 form an imaginary tangent circle on the left half of the furnace, and corner burners #5~#8 form an imaginary tangent circle on the right half of the furnace. The two tangent circles are in opposite directions.

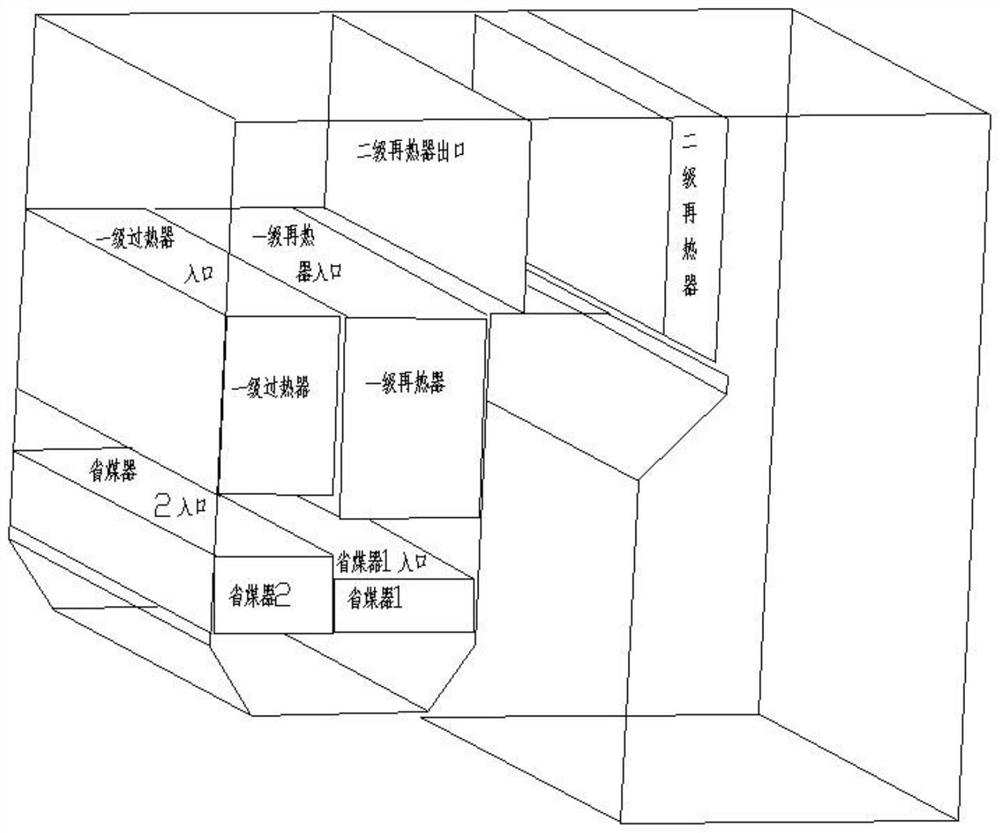

[0038] Boiler superheater consists of five parts: ceiling superheater, rear cladding superheater, primary superheater, secondary superheater and tertiary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com