Spiral gunpowder accelerator

An accelerator and gunpowder technology, applied in the field of spiral gunpowder accelerators, to achieve the effect of increasing the pressure difference between the front and back of the projectile, increasing the acceleration of the projectile, and increasing the exit velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

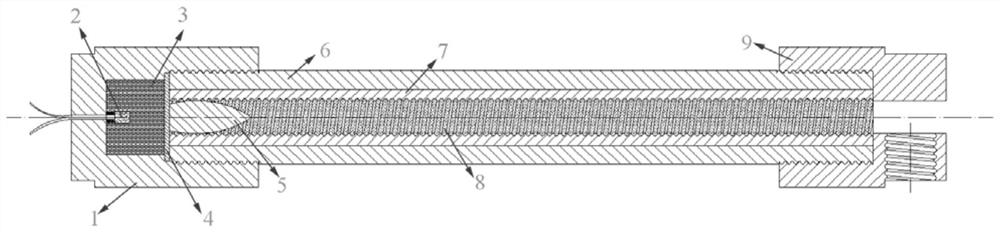

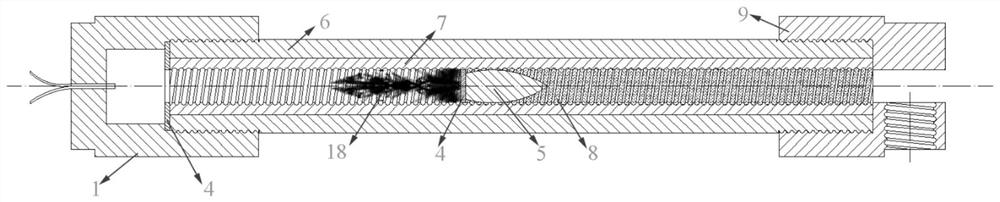

[0031] refer to figure 2 Carry out a section of gun barrel installation, at first follow-up propellant 8 is installed in the barrel inner shell 7, in barrel inner shell 7 one end, be placed in the barrel shell 6 after filling projectile 5; Then according to excitation charge 2, propellant charge 3, Cut pieces 4 are installed in the firing mechanism 1 in sequence, and then one end barrel housing 6 with the projectile 5 is embedded in the firing mechanism 1 in a threaded manner, and the other end is connected to the outlet cap 9 to complete the installation of the barrel as a whole.

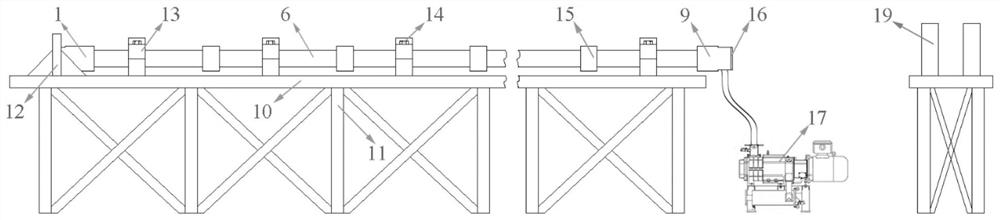

[0032] refer to figure 1 First, the barrel installation platform 10, bracket 11 and other components are assembled into a barrel installation base with bolts, and the fixed baffle 12 is placed in the middle of the front and rear triangle plates of the barrel installation platform 10 to fix; then the above-mentioned installed barrel is placed On the barrel installation platform 10, the launching m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com