Hot air supply rapid adjusting system for icing wind tunnel and air supply method

A technology for adjusting the system and hot gas, which is applied in the field of wind tunnel testing, and can solve problems such as complex test procedures, slow stabilization time of model inlet temperature, and large flow changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

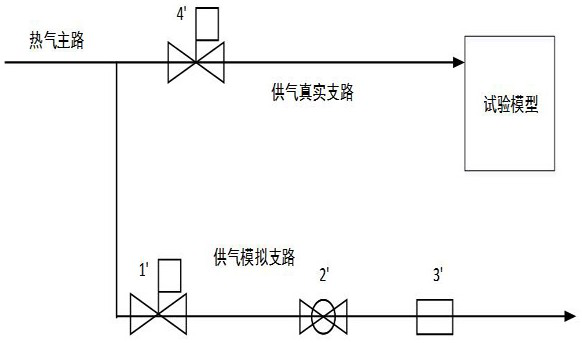

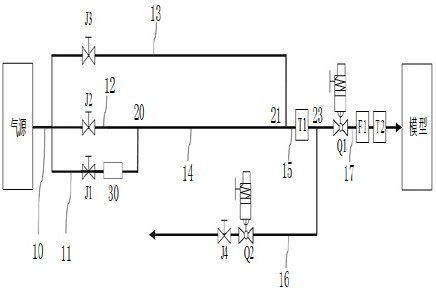

[0041] Such as figure 2Shown is a schematic diagram of a hot air supply rapid adjustment system for icing wind tunnels in Embodiment 1 of the present invention. A hot air supply rapid adjustment system for icing wind tunnels in Embodiment 1 of the present invention includes: Air source, air source main road 10, hot air branch 11, first cold air branch 12, second cold air branch 13, first mixing branch 14, second mixing branch 15, simulation branch 16, real branch 17, of which:

[0042] The inlet of the air source main road 10 is connected to the air source outlet, and the outlet of the air source main road 10 is simultaneously connected to the entrance of the hot air branch 11, the entrance of the first cold air branch 12, and the entrance of the second cold air branch 13. connect;

[0043] The gas source is used to generate the gas for the anti-icing test, and when the gas is generated from the gas source, it is in a state of natural temperature;

[0044] In order to spec...

Embodiment 2

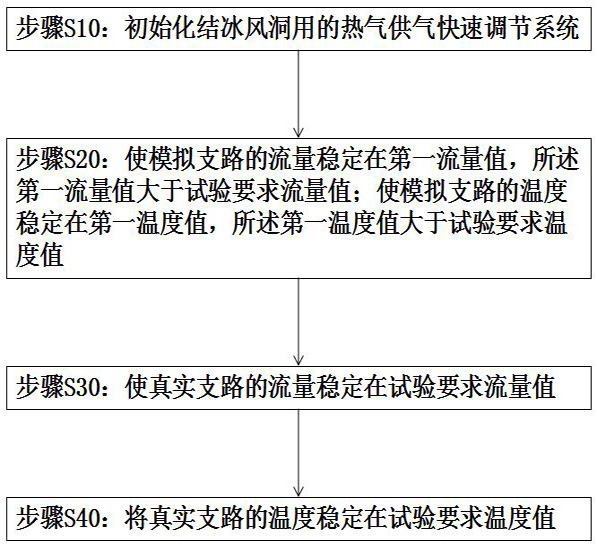

[0060] Such as image 3 Shown is a schematic diagram of the air supply method using the above-mentioned hot air supply quick adjustment system for the icing wind tunnel in Embodiment 2 of the present invention, which includes the following steps:

[0061] Step S10: Initialize the hot air supply rapid adjustment system for the icing wind tunnel;

[0062] Step S20: Stabilize the flow of the simulation branch 16 at a first flow value, the first flow value is greater than the test required flow value; stabilize the temperature of the simulation branch 16 at a first temperature value, the first temperature value is greater than Test required temperature value;

[0063] Step S30: Stabilize the flow of the real branch 17 at the test required flow value;

[0064] Step S40: Stabilize the temperature of the real branch 17 at a temperature value required by the test.

[0065] Further, in the step S10, the first regulating valve J1, the second regulating valve J2, the second ball valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com