Electrified defect elimination method and device for post insulator of cable terminal

A technology for post insulators and cable terminals, which is applied in the directions of supporting insulators and equipment for connecting/terminating cables, etc. It can solve the problems of long power outage application process, low efficiency of operation methods, long time-consuming process of eliminating defects, etc., and achieve fast elimination methods. , The effect of improving low efficiency and shortening operation process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

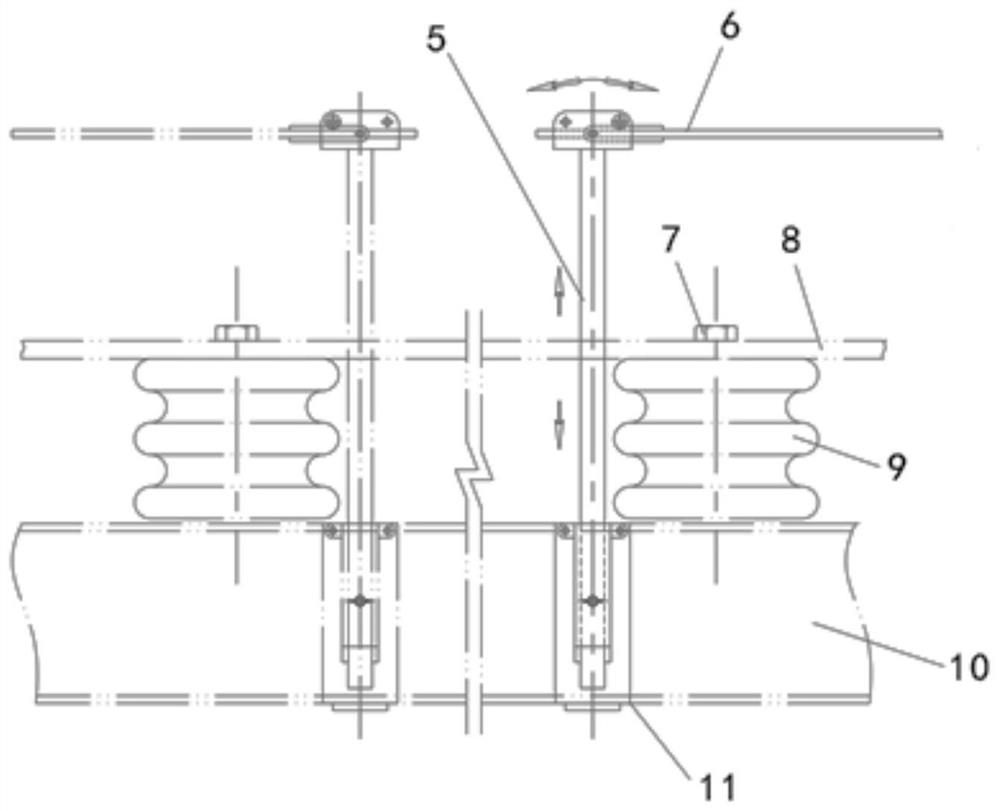

[0063]The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

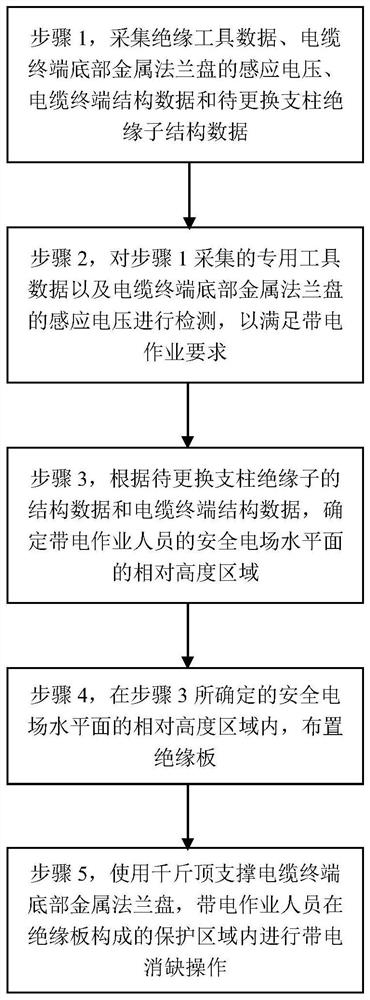

[0064] like figure 1 , the steps of the live defect elimination method for the cable terminal post insulator are as follows:

[0065] Step 1. Collect the data of insulating tools, the induced voltage of the metal flange at the bottom of the cable terminal, the structural data of the cable terminal and the structural data of the post insulator to be replaced.

[0066] specifically,

[0067] In step 1,

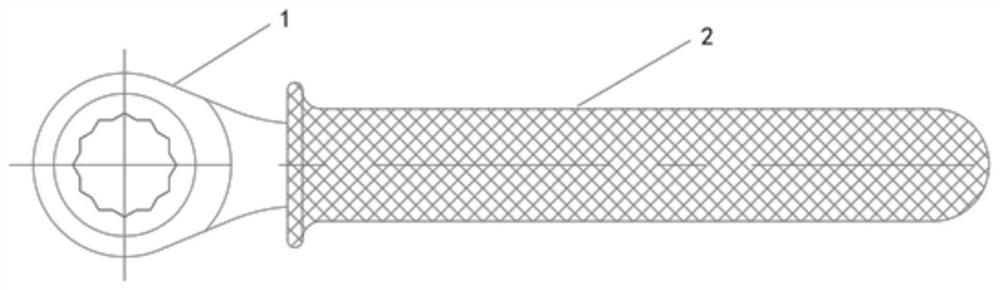

[0068] Insulation tool data include: insulation test validity period and insulation integrity of insulation baffle, insulation test validity period and insulation integrity of insulation wrench;

[0069] The structural data of the cable terminal includes: the installation height of the shed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com