Battery charging circuit, battery pack and battery pack charging system

A battery charging and circuit technology, which is applied to battery disconnecting circuits, battery circuit devices, circuit devices, etc., can solve the problems of high cost and large volume, and achieve the effects of low cost, strong overcurrent capability and low heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

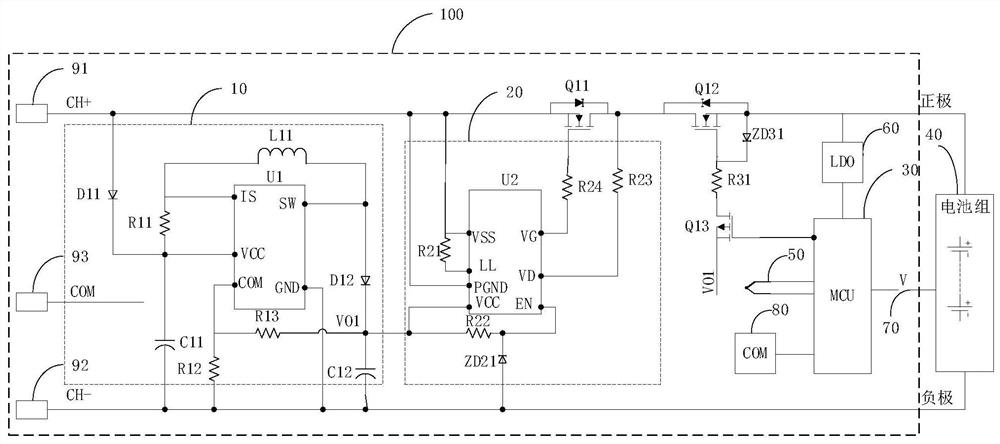

[0080]In this embodiment, iffigure 1 As shown, the battery charging circuit 100 is applied to a DC charging high side control, the power supply unit 10, is powered at a charge terminal, and the battery charging circuit 100 passes through the charging terminal andFigure 6 The output terminal of the DC charger 600 is connected, the NMOS tube Q11 is an NMOS tube having a body diode.

[0081]Specifically, such asfigure 1 As shown, the power supply unit 10 includes a boost circuit chip U1 (model, for example, MC34063), resistance R11, resistor R12, resistor R13, diode D11, diode D12, inductance L11, capacitor C11, and capacitance C12; the diode D11; The anode is connected to the source of the charging positive terminal 91 and the NMOS tube Q11, and the cathode of the diode D11 is connected to the charging negative terminal 92 via a capacitor C11, and the cathode of the diode D11 is respectively charged. The VCC pin of the circuit chip U1 and one end of the resistor R11 are connected, and th...

Embodiment 2

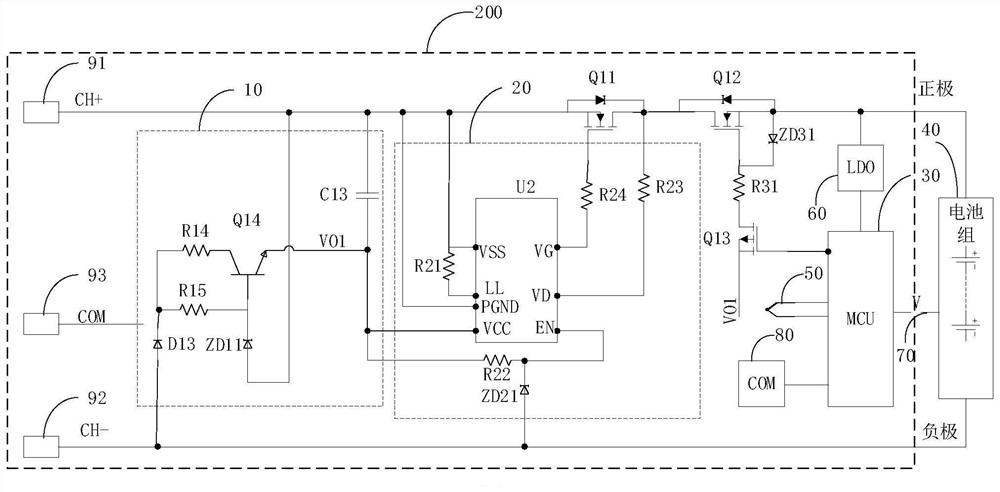

[0088]In this embodiment, iffigure 2 As shown, the battery charging circuit 200 is applied to AC charging high side control, the power supply unit 10 is powered at a charge terminal, and the battery charging circuit 200 is passed through the charging terminal andFigure 7 The output terminal of the AC charger 700 is connected, the NMOS tube Q11 is an NMOS tube having a body diode.

[0089]Specifically, such asfigure 2 As shown, the power supply unit 10 includes a resistor R14, a resistor R15, an NPN triode Q14, a capacitor C13, a diode D13, and a regulator diode ZD11; the base of the NPN triode is respectively composed to the cathode of the regulator diode ZD11, respectively. One end of the resistor R15 is connected, and the anode of the voltage regulator diode ZD 11 is connected to the source of the charging positive terminal 91 and the NMOS tube Q11, and the other end of the resistor R15 respectively corresponds to one end and the diode of the resistor R14, respectively. The cathode c...

Embodiment 3

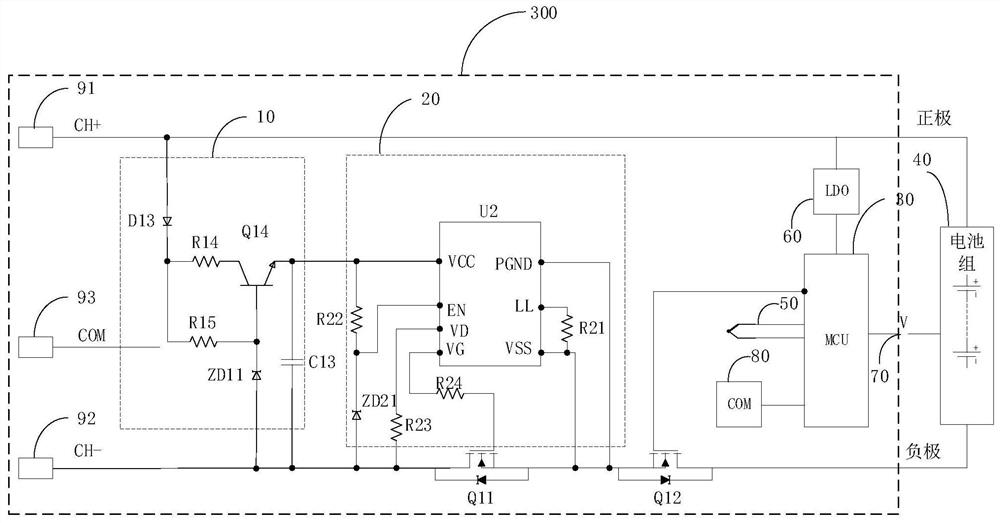

[0096]In this embodiment, ifimage 3 Design, the battery charging circuit 300 is suitable for a DC charging low-side control, the power supply unit 10 is powered at a charge terminal, and the battery charging circuit 300 passes through the charging terminal andFigure 6 The output terminal of the DC charger 600 is connected to the NMOS tube Q11 is an NMOS tube having a body diode.

[0097]Specifically, such asimage 3 As shown, the power supply unit 10 includes a resistor R14, a resistor R15, an NPN triode Q14, a capacitor C13, a diode D13, and a regulator diode ZD11; the base of the NPN triode is respectively composed to the cathode of the regulator diode ZD11, respectively. One end of the resistor R15 is connected, and the anode of the regulator diode ZD 11 is connected to the drain of the charging negative terminal 92 and the NMOS tube Q11, and the other end of the resistor R15 is respectively connected to one end and the diode D13 of the resistor R14, respectively. The cathode connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com