Stirring device for road and bridge construction

A technology of mixing device and mixing mechanism, which is applied to cement mixing device, unloading device, clay preparation device, etc., can solve the problems of uneven mixing of concrete mixing device in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

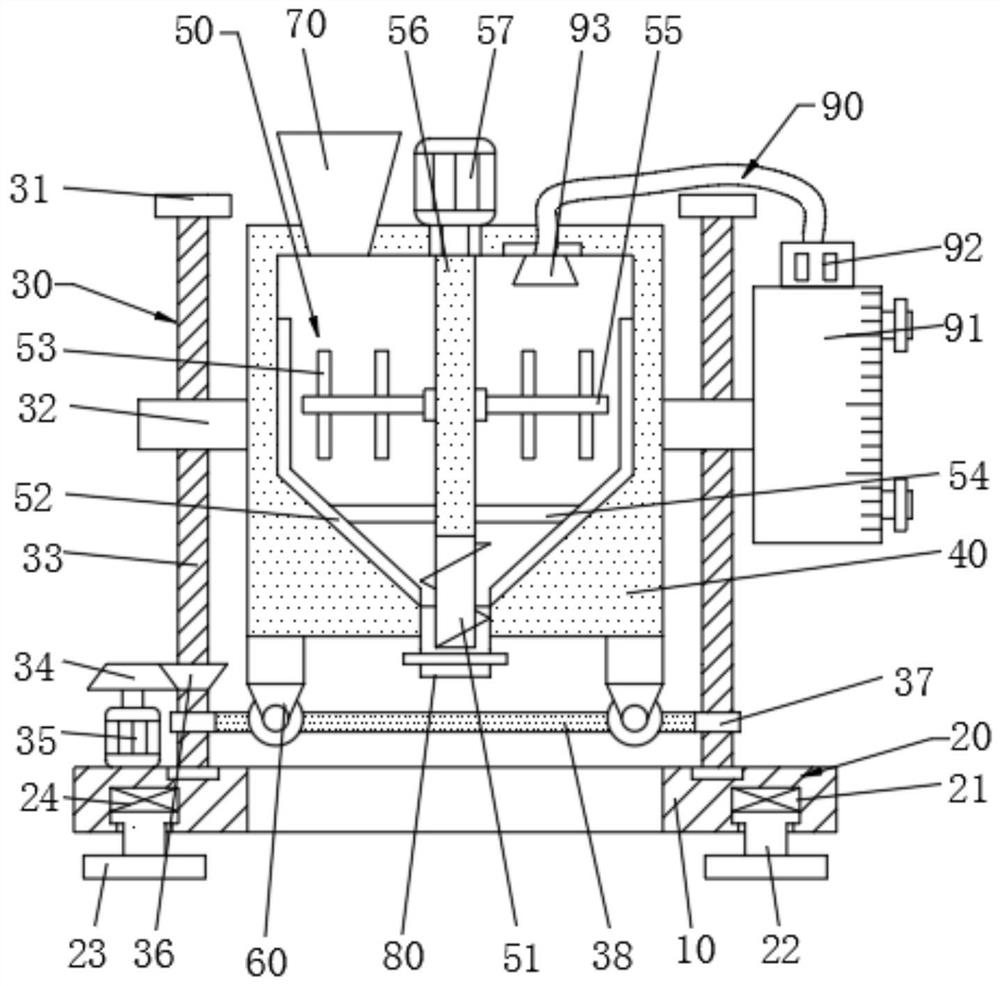

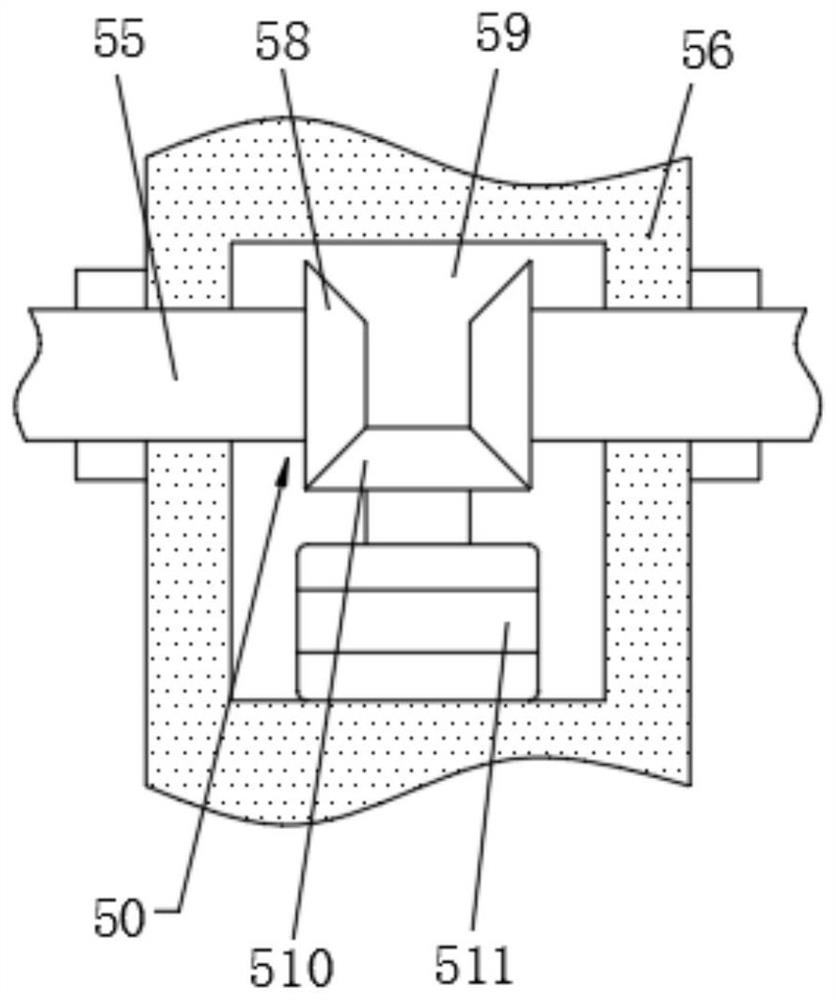

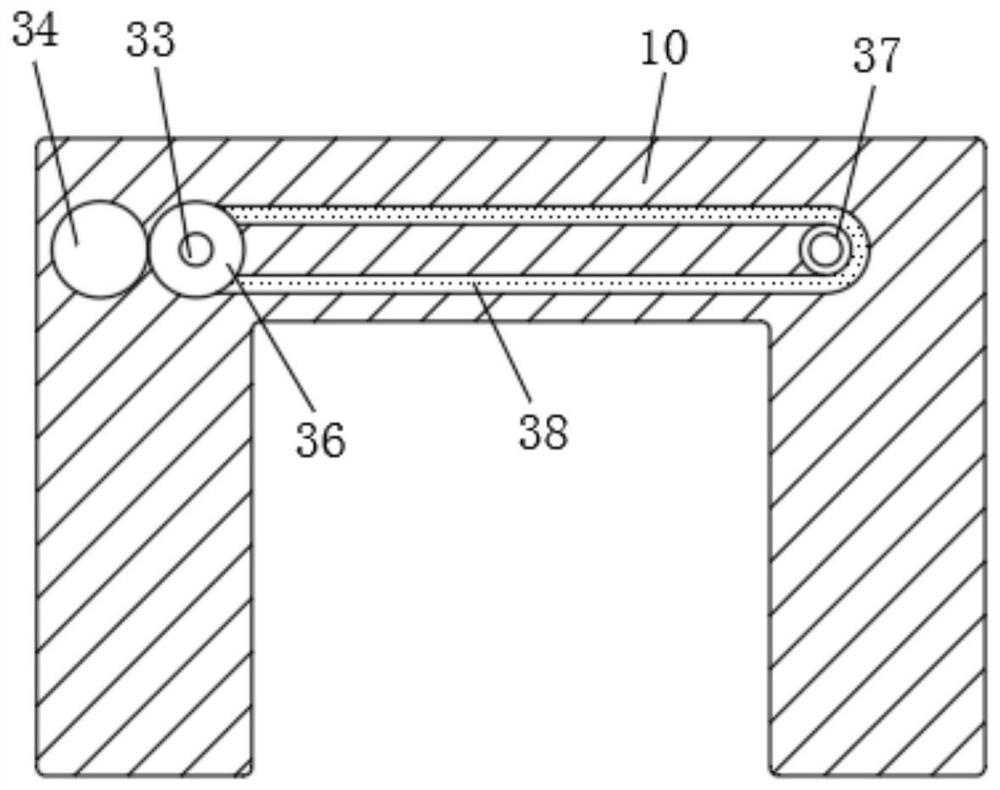

[0019] see Figure 1-Figure 4 , a road and bridge construction stirring device, comprising a base 10, the shape of the base 10 is U-shaped, the base 10 is provided with a lifting mechanism 30, the lifting mechanism 30 is provided with a cylinder body 40, and the cylinder body 40 is provided with a stirring mechanism 50, One side of lifting mechanism 30 is provided with water adding mechanism 90, and the bottom end of base 10 is provided with support mechanism 20, and stirring mechanism 50 comprises first motor 57, and the model of first motor 57 is TCB8024B3, by being provided with first motor 57, starts To drive the rotating rod 56 to rotate, the end of the rotating shaft of the first motor 57 runs through the cylinder body 40 and is provided with a rotating rod 56. The bottom end of the rotating rod 56 is provided with a helical wing 51, which facilitates uniform discharge The rotating rod 56 is provided with a connecting rod 54, and the number of the connecting rod 54 is tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com