Nano composite migration type steel bar corrosion inhibitor suitable for concrete in marine environment

A steel rust inhibitor and nano-composite technology, applied in the field of building materials, can solve the problems of poor migration performance and weak post-protection ability of migratory rust inhibitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

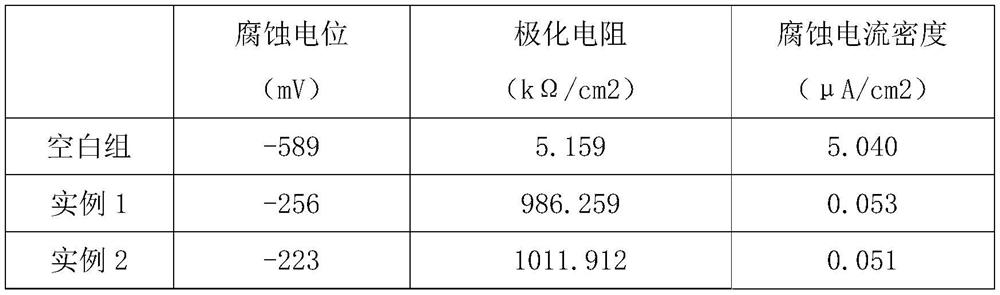

Examples

Embodiment 1

[0029] The formula of the nanocomposite migratory steel bar rust inhibitor used is: 15% of aminomethyl propanol; 5% of monoethanolamine benzoate; 5% of sodium monofluorophosphate; the rest is water, and the sum of the above components is 100%.

Embodiment 2

[0031] The formula of the nano-composite migratory steel rust inhibitor used is: 15% of aminomethyl propanol; 5% of monoethanolamine benzoate; 5% of sodium monofluorophosphate; 2% of sodium hexametaphosphate; 2% of sodium polyacrylate; Divided into water, the sum of the above components is 100%.

Embodiment 3

[0033] The formula of the nanocomposite migratory steel rust inhibitor used is: 15% of aminomethyl propanol; 5% of monoethanolamine benzoate; 5% of sodium monofluorophosphate; 5% of sodium hexametaphosphate; 5% of sodium polyacrylate; Divided into water, the sum of the above components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com