Cement-based polyurethane permeable waterproof material and preparation method thereof

A waterproof material, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the adhesion defects of coatings and primer materials, and the compatibility between coatings and two-component polyurethane is not good, not suitable for Hybrid sports fields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the urethane permeable waterproof material described in the above technical solution, comprising the following steps:

[0037] Dehydration and degassing of polyether polyol N220 and polyether polyol N330 under reduced pressure at 110°C for 100 minutes to obtain dehydrated polyether polyol;

[0038] Add the dehydrated polyether polyol into a container with a thermometer and a stirrer, cool down to 60°C, then add isocyanate MDI-50, raise the temperature to 78°C, react at constant temperature for 2 hours, then cool down to 60°C and add dilution agent, silicone coupling agent and nano-alumina, stirred and mixed at a temperature below 60°C for 30 minutes to obtain the urethane permeable waterproof material.

[0039] In the present invention, the construction method of the cement-based polyurethane permeable waterproof material is preferably: use a roller brush to apply the above polyurethane permeable waterproof mat...

Embodiment 1

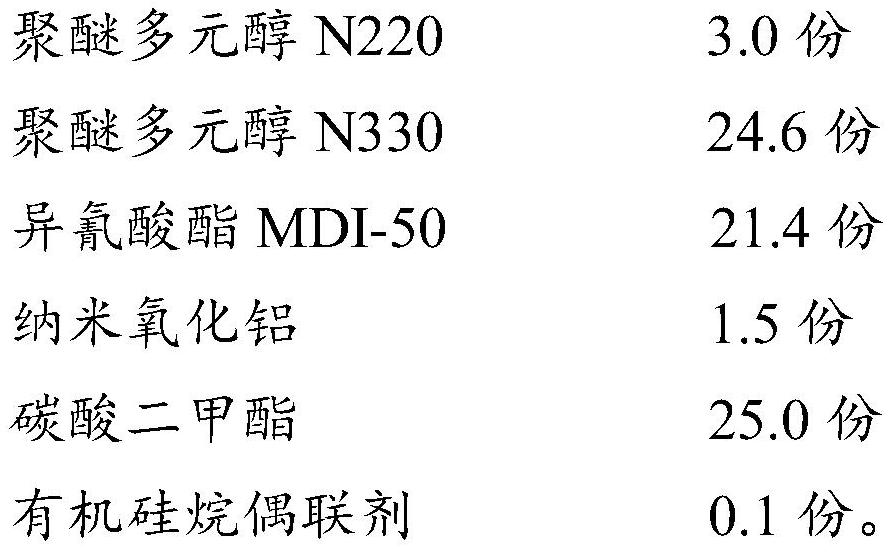

[0042] Composition of polyurethane permeable waterproofing materials based on cement base:

[0043] 3.0 parts of polyether polyol N220, 24.6 parts of polyether polyol N330, 21.4 parts of isocyanate MDI-50, 1.5 parts of nano-alumina, 25.0 parts of dimethyl carbonate and 0.1 part of organosilane coupling agent; the polyether polyol The molecular weight of N220 is 2000; the molecular weight of the polyether polyol N330 is 3000; the isocyanate is modified diphenylmethane diisocyanate, which is liquid at normal temperature;

[0044] Preparation:

[0045] Dehydration and degassing of polyether polyol N220 and polyether polyol N330 under reduced pressure at 110°C for 100 minutes to obtain dehydrated polyether polyol;

[0046] Add the dehydrated polyether polyol into a container with a thermometer and a stirrer, cool down to 60°C and then add isocyanate MDI-50, raise the temperature to 78°C, react at constant temperature for 2 hours, then cool down to 60°C and add carbonic acid Dime...

Embodiment 2

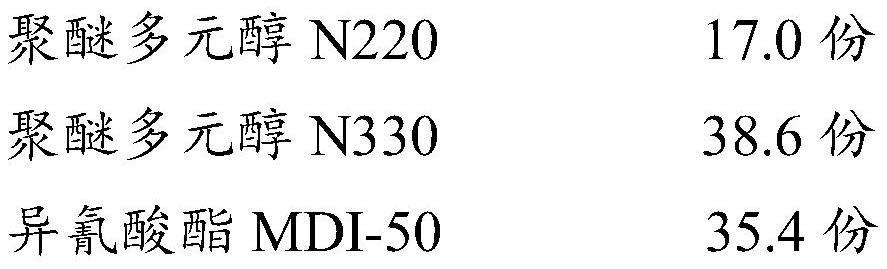

[0050] Composition of polyurethane permeable waterproofing materials based on cement base:

[0051] 17.0 parts of polyether polyol N220, 38.6 parts of polyether polyol N330, 35.4 parts of isocyanate MDI-50, 2.9 parts of nano-alumina, 30.0 parts of dimethyl carbonate and 0.3 part of organosilane coupling agent; the polyether polyol The molecular weight of N220 is 2000; the molecular weight of the polyether polyol N330 is 3000; the isocyanate is modified diphenylmethane diisocyanate, which is liquid at normal temperature;

[0052] Preparation:

[0053] Dehydration and degassing of polyether polyol N220 and polyether polyol N330 under reduced pressure at 110°C for 100 minutes to obtain dehydrated polyether polyol;

[0054] Add the dehydrated polyether polyol into a container with a thermometer and a stirrer, cool down to 60°C, then add isocyanate MDI-50, raise the temperature to 78°C, react at constant temperature for 2 hours, then cool down to 60°C and add carbonic acid Dimeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com