Method for detecting iron notch depth by using iron notch drill

The technology of a taphole machine and taphole is applied in the field of using taphole machine to detect taphole depth, and can solve problems such as taphole depth error detected by taptop machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

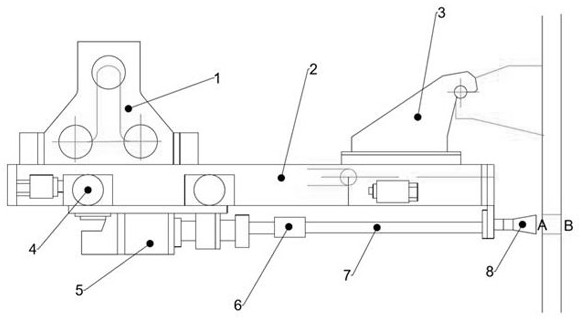

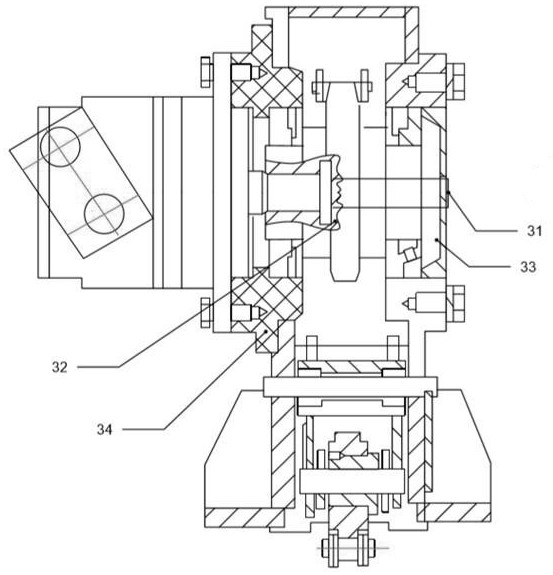

[0029] Such as Figure 1-4 As shown, it is a tap hole machine that can detect the depth of the tap hole, including a driving device 1, a traveling trolley 4, and a hydraulic rock drill 5 arranged on the traveling trolley 4. The hydraulic rock drill 5 is connected with a drilling device, and the drilling device consists of The drill pipe sleeve 6, drill pipe 7, and drill bit 8 installed on the hydraulic rock drill 5 successively from left to right; The driving device 1 includes a transmission shaft 31 , a transmission chain 32 , an end cover 33 and a base 34 , and one end of the transmission shaft 31 drives the traveling trolley 4 to run through the transmission chain 32 .

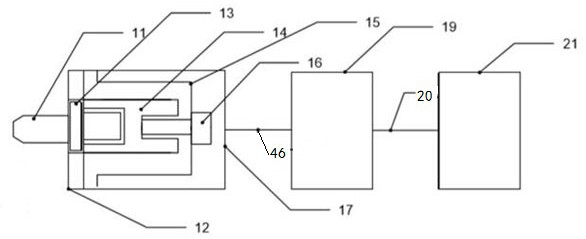

[0030] A detection system is also provided on the taphole machine, the detection system is installed on the end cover 33 of the driving device 1 through the flange 12, and the bearing 13 is installed in the flange 12; the detection system includes a tapered joint 11, a flexible coupling Device 14, encoder ...

Embodiment 2

[0034] Such as Figure 5As shown, when the iron hole needs to be opened, the trolley 4 drives the drill pipe 7 to drill forward. At this time, the drill bit 8 of the drill pipe 7 moves from point A to point B. Since this distance is an empty stroke, the speed is very fast. , the speed is 70mm / s, when it touches the gun mud B and starts to drill and punch the gun mud, the speed is 9-10mm / s, when drilling to point C, the drill bit needs to be replaced due to the damage of the drill bit, so the drill pipe can only be withdrawn, record at this time The first distance is BC. When the drill bit is replaced, it starts drilling again. The speed from the beginning to point D is an empty stroke, so the speed is faster than 70mm / s, so this distance is not recorded. When drilling from point D When reaching point E, the speed is 9-10mm / s. When drilling to point E, the drill bit needs to be replaced due to the damage of the drill bit, so the drill pipe can only be withdrawn. At this time, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com