Spinning ball removing device

A technology of walking bracket and roller, which is applied in the direction of textiles and papermaking, fabric surface trimming, etc., and can solve the problems of textile fabric damage, pilling again, and textile fabric off-line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

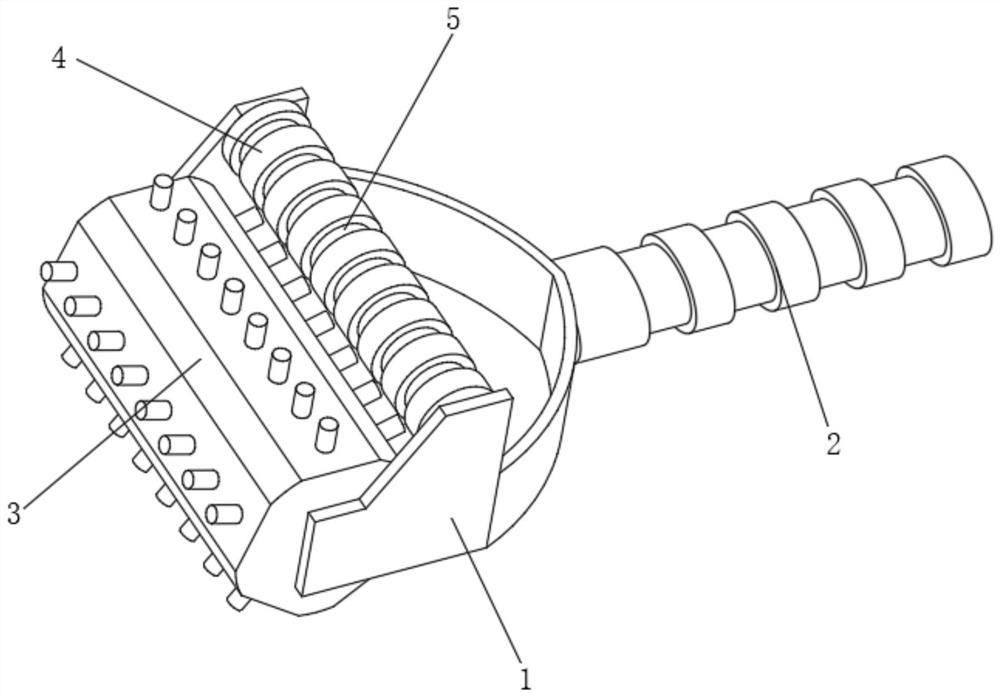

[0033] Such as Figure 1-2 As shown, the present invention provides a technical solution: a textile deballing device, including a walking frame 1, a drive handle 2 is fixedly connected to the middle position on the back of the walking frame 1, and a driving handle 2 is fixedly connected to the position near the front side of the walking frame 1. There is a contact stripping mechanism 3, and the walking bracket 1 is internally measured and is fixedly connected to the position above the back of the contact stripping mechanism 3. There is a cleaning sweep wheel 4, and the outer surface of the cleaning sweep wheel 4 is uniformly provided with scraping grooves 5;

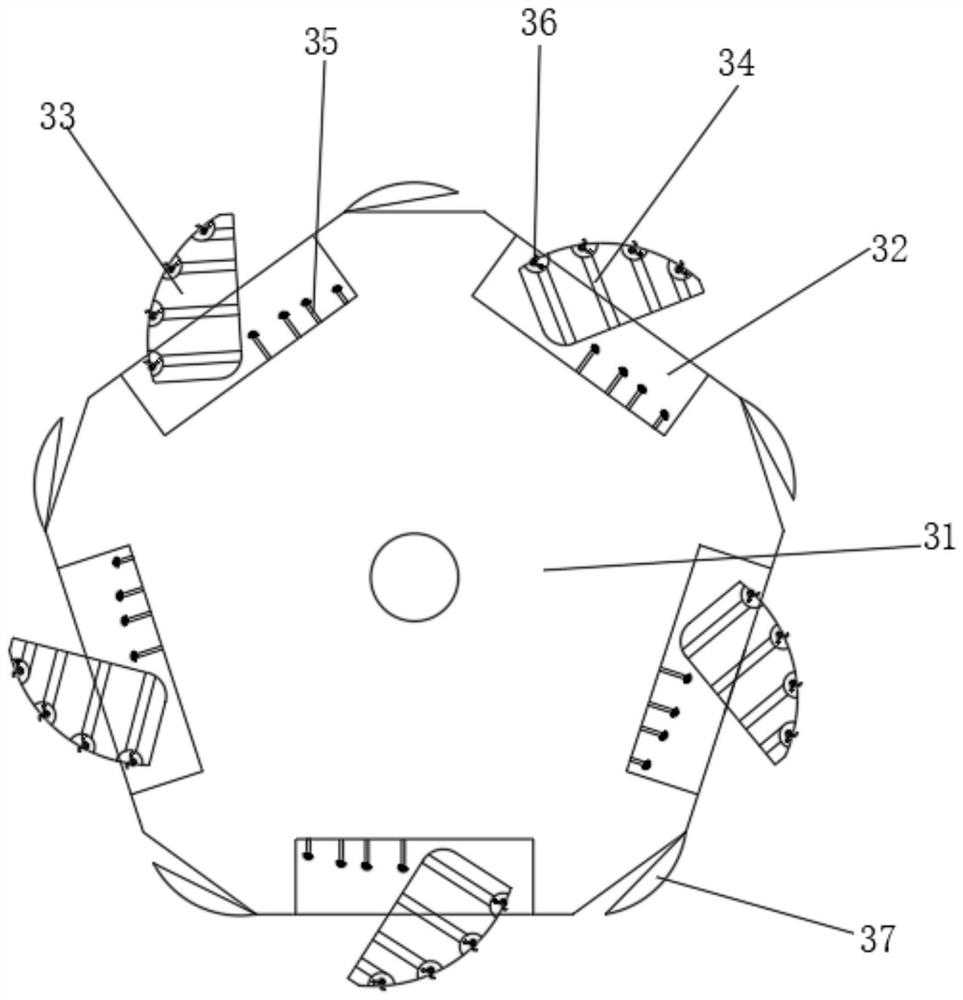

[0034]The contact and deballing mechanism 3 includes a walking roller 31, the two sides of the walking roller 31 are rotationally connected with the walking support 1, the outer surface of the walking roller 31 is evenly provided with a movable retaining groove 32, and one side of the movable retaining groove 32 is rotata...

Embodiment 2

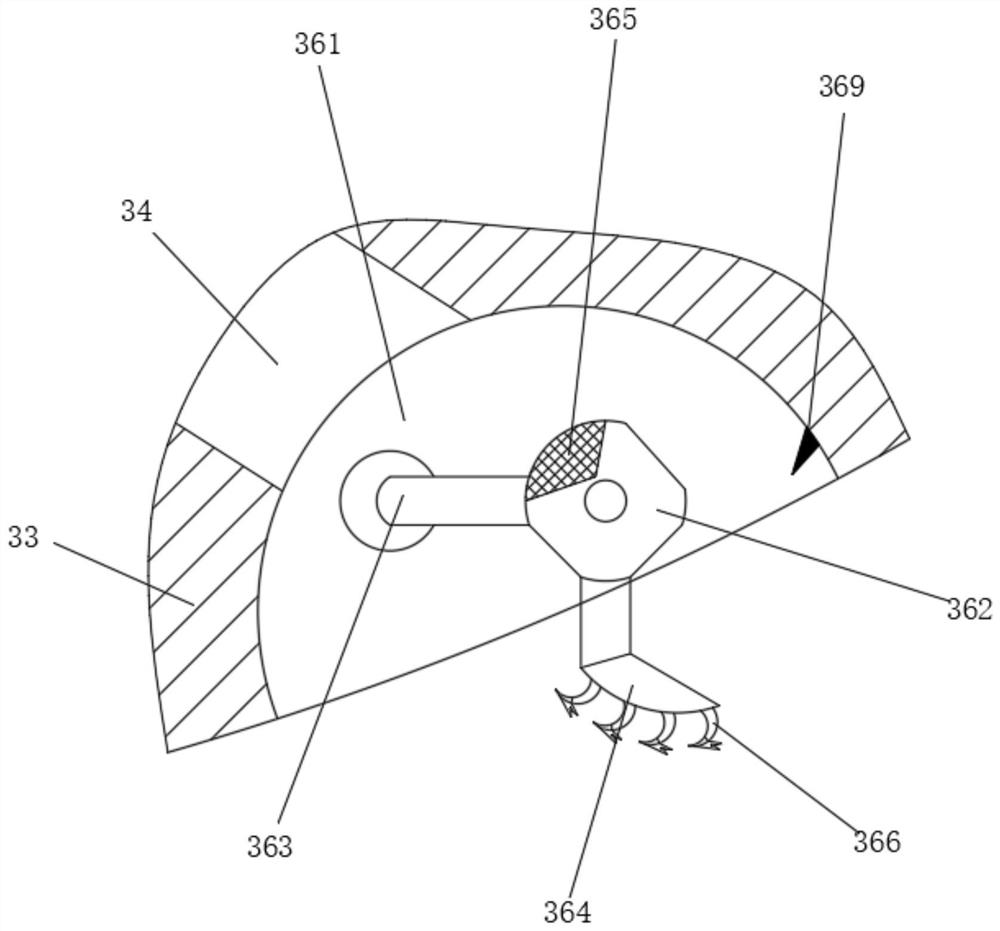

[0036] Such as Figure 3-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a textile deballing device, the contact scraper assembly 36 includes an adjustment circular groove 361, and the adjustment circular groove 361 is arranged on the contact drag reduction arc block 33 Inside, the adjusting circular groove 361 communicates with the conduction inner groove 34 , the inside of the adjusting circular groove 361 is rotatably connected with a transmission disk 362 , and the outer surface of the transmission disk 362 is fixedly connected with a drag reducing roller 363 .

[0037] The outer surface of the transmission disc 362 is fixedly connected with a fitting extrusion block 364, and the fitting extrusion block 364 is vertically arranged with the drag reducing roller 363. The outer surface of the transmission disc 362 is provided with a directional conductive groove 365, and the directional conductive groove 365 and the The conduction...

Embodiment 3

[0041] Such as Figure 5-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a textile deballing device, the end cutting assembly 37 includes a support carrier 371, and the top of the support carrier 371 is in contact with the walking The roller 31 is fixedly connected, and the bottom of the support carrier 371 is fixedly connected with a lamination scraper 372 .

[0042] The surface of the front surface of the laminating scraper 372 is evenly provided with guiding and restricting conical grooves 373 , and the front of the support carrier 371 is evenly provided with surplus material storage grooves 374 , and the back of the guiding and restricting tapered grooves 373 communicates with the surplus material storage grooves 374 .

[0043] A cutting blade 375 is evenly and fixedly connected to both ends of the fitting scraper 372 , and a transmission guide wheel 376 is connected to the back of the fitting scraper 372 in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com