Waste paper regeneration environment-friendly equipment

An environmental protection equipment and technology for waste paper, applied in papermaking, paper recycling, textiles and papermaking, etc., can solve the problems of easy retention, reduced pulp flow, and reduced pulp fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

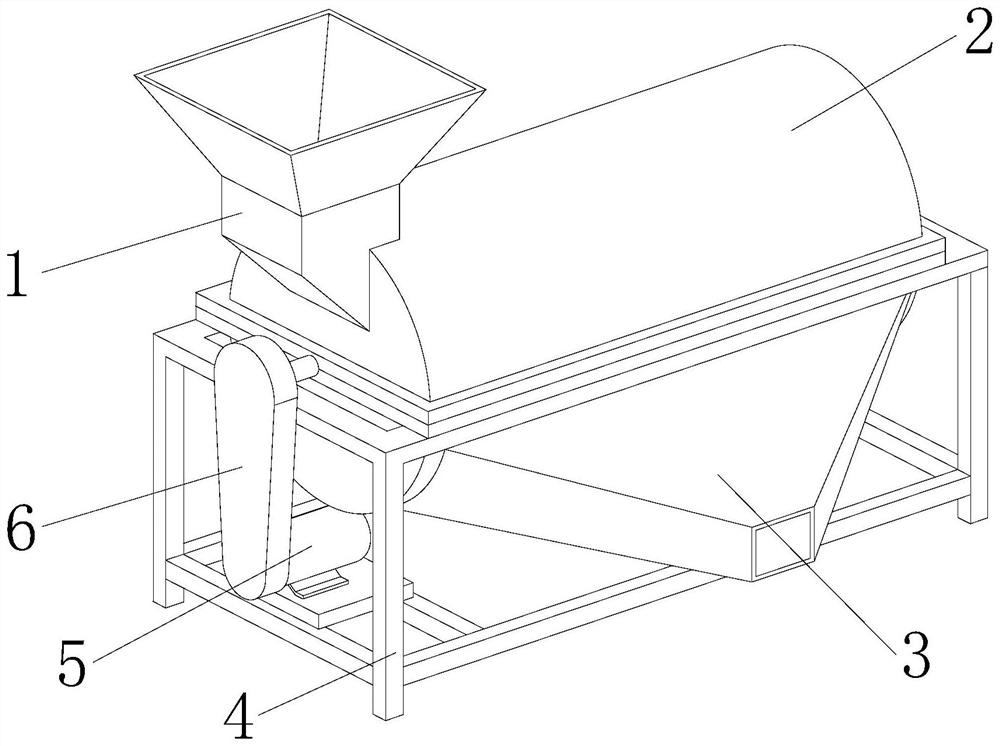

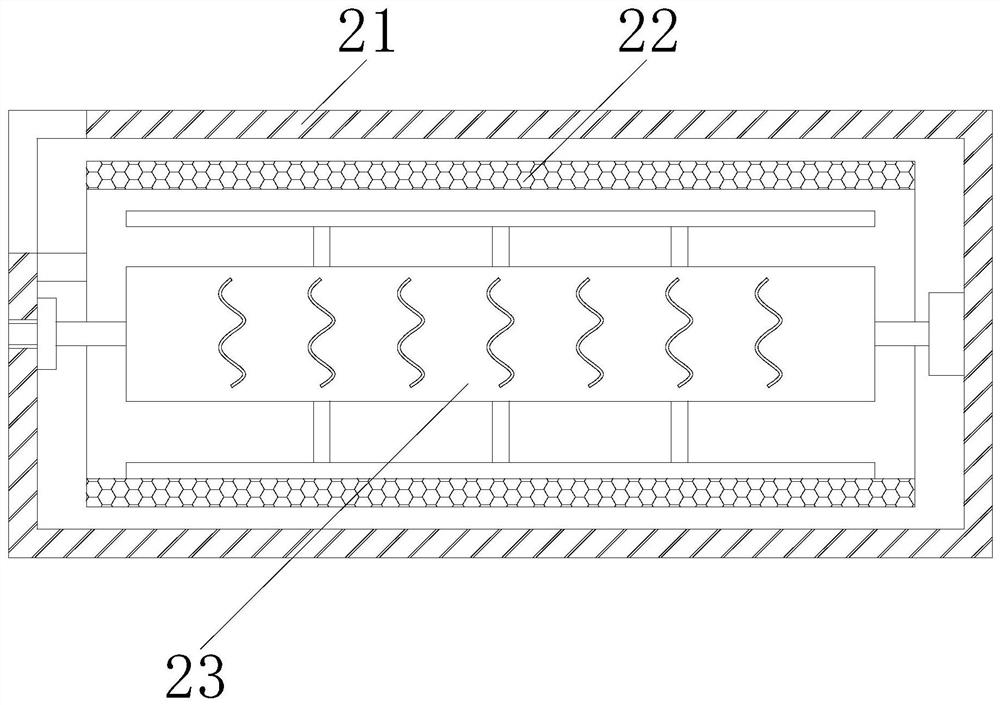

[0022] as attached figure 1 to attach Figure 5 Shown:

[0023] The waste paper recycling and environmental protection equipment of the present invention comprises a hopper 1, a beating device 2, a discharge port 3, a support frame 4, a motor 5, and a belt cover 6, and the hopper 1 is embedded and installed on the upper left of the beating device 2 The middle part of the front end of the beating device 2 is embedded with a discharge port 3 and communicated with each other. The outer middle part of the beating device 2 is welded to the upper end of the support frame 4, and the motor 5 is arranged at the lower left end of the support frame 4. The output end of the motor 5 is installed inside the lower end of the belt cover 6, and the upper end of the belt cover 6 is located in the middle of the left end of the beating device 2. The inside of the beating device 2 rotates synchronously with the output end of the motor 5. The beating device 2 includes a beating cylinder 21 , filt...

Embodiment 2

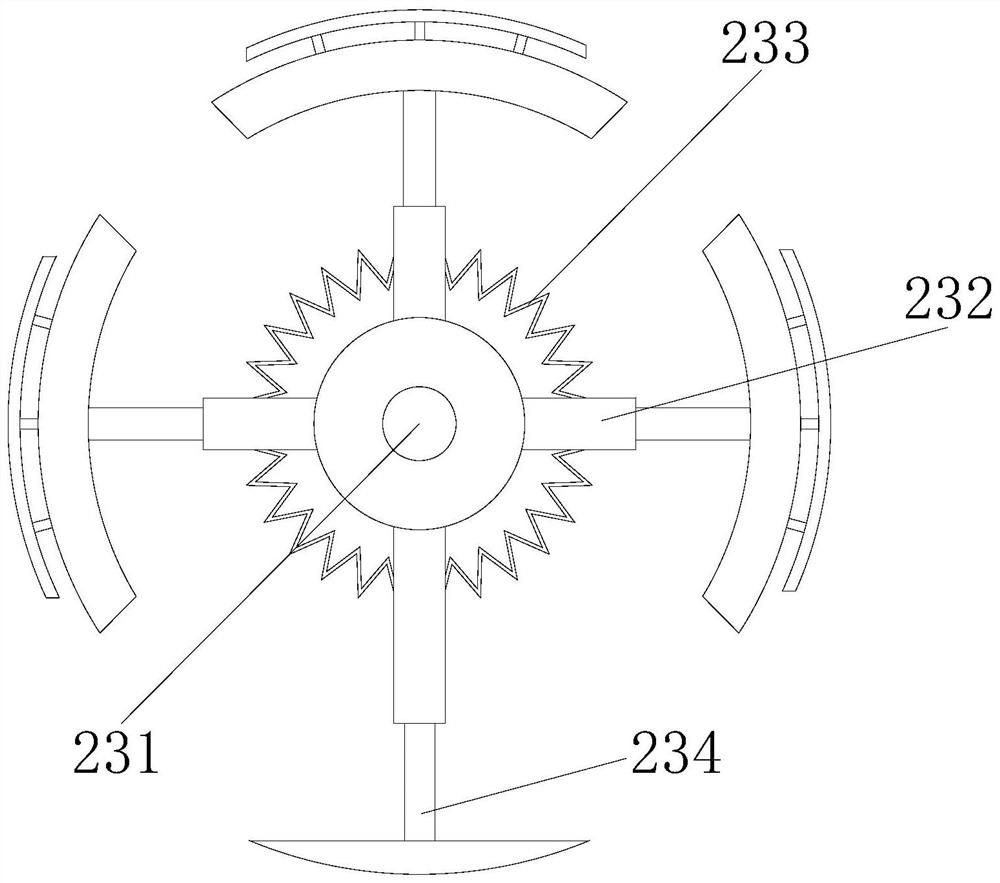

[0030] as attached Image 6 to attach Figure 7 Shown:

[0031] Wherein, the cleaning device 234 includes a pole 341, a partition 342, and a scraping mechanism 343, the top of the pole 341 is welded to the lower end of the rotating shaft 231, and the lower end of the pole 341 is welded to the middle of the upper surface of the partition 342. The partition 342 is located inside the upper end of the scraping mechanism 343, and the support rod 341 and the partition 342 are all provided with three, and the three support rods are all arranged at the upper end of the partition 342 in the middle, so that the support rod 341 is arranged on the upper end of the scraping mechanism. 343 to support the ability, and at the same time, the scraped pulp can be blocked by the three partitions 342, so that the pulp is rotated to the top and then falls, and the secondary beating is continued to improve the fineness of the pulp.

[0032] Wherein, the scraping mechanism 343 includes a scraping g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com