Heat preservation and floor heating integrated reinforced concrete two-way laminated slab and pouring process thereof

A technology of laminated slab and reinforced concrete, which is applied in the direction of floor slabs, buildings, building components, etc., can solve the problems of high installation cost and no self-insulation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

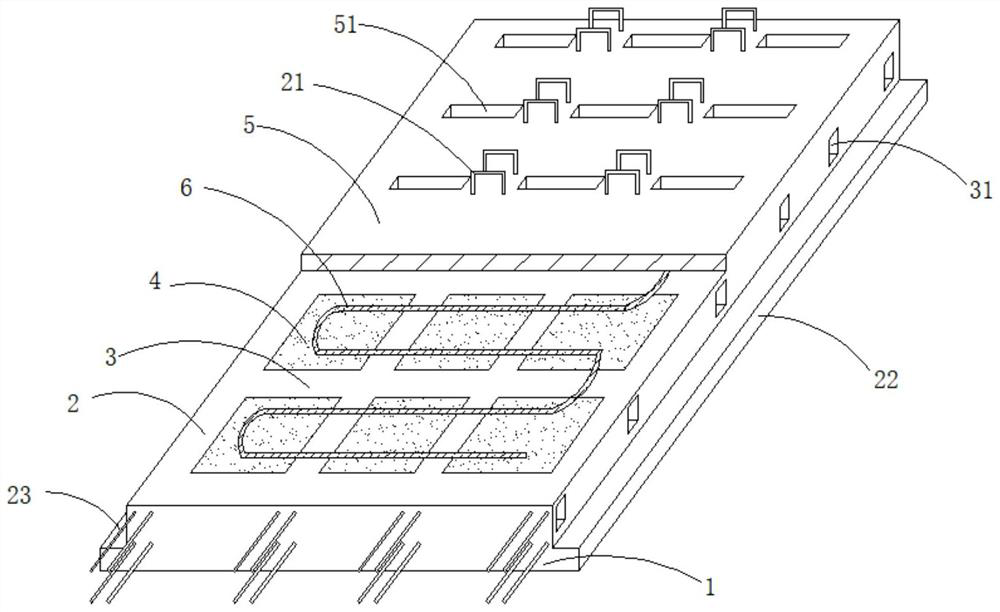

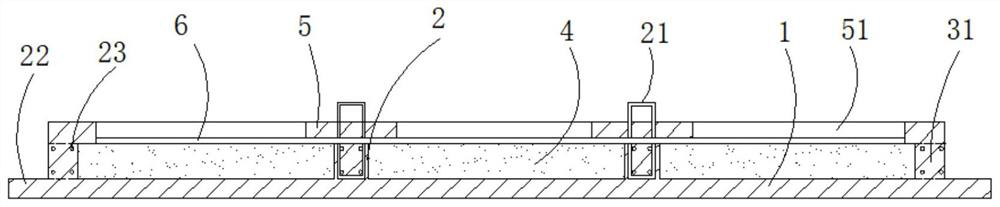

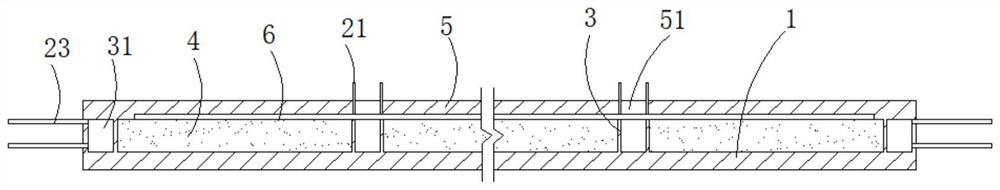

[0042] refer to Figure 1-3 , a reinforced concrete two-way dense rib sandwich laminated panel with thermal insulation and floor heating, including a bottom plate 1, a longitudinal rib beam 2 and a transverse rib beam 3, a foam block 4 and a panel 5, and the foam block 4 is located between the bottom plate 1 and the longitudinal rib beam 2. In the cavity formed by the transverse rib beam 3 and the bottom plate 5, a floor heating pipe 6 is laid between the foam block 4 and the panel 5 for heating.

[0043] Further, a transverse through hole 31 is provided inside the transverse rib beam 3 , and a transverse connecting steel bar for the laminated slab can be inserted into the transverse through hole 31 for the transverse connection of the laminated slab.

[0044] Further, above the transverse rib beam 3, the panel 5 is provided with a strip-shaped square hole 51 whose bottom is connected with the transverse through-hole 31, and after pouring concrete, the strip-shaped square hole...

Embodiment 2

[0052] This embodiment proposes a prefabricated pouring process based on the integrated reinforced concrete two-way laminated slab with upper insulation and floor heating, including the following steps:

[0053] Step A1: laying the bottom mold and side molds;

[0054] Step A2: Lay the base plate 1, and mark the placement position of the foam block 4 on the base plate 1;

[0055] Step A3: Place the foam block 4 on the bottom plate 1 according to the marked position, and fix the connecting steel bar 23 and stirrup 21 at the position of the longitudinal rib beam 2, and place a module with the same shape as the transverse through hole at the position of the transverse rib beam 3 A;

[0056] Step A4: Pouring the longitudinal rib beam 2 and the transverse rib beam 3, keeping the longitudinal rib beam 2, the transverse rib beam 3 and the foam block 4 on the same plane;

[0057] Step A5: laying the floor heating pipe 6 on the upper surfaces of the longitudinal rib beam 2, the transv...

Embodiment 3

[0062] This embodiment also proposes an on-site pouring process based on the above-mentioned thermal insulation and floor heating integrated reinforced concrete two-way laminated slab, which includes the following steps:

[0063] Step B1: laying a bottom form on the beam, and fixing and positioning the connecting steel bar 23, where the connecting steel bar 23 does not protrude from the longitudinal rib beam 2;

[0064] Step B2: Lay the bottom plate, and mark the placement position of the foam block 4 on the bottom plate;

[0065] Step B3: Place the foam block 4 on the bottom plate 1 according to the marked position;

[0066] Step B4: Pouring the longitudinal rib beam 2 and the transverse rib beam 3, keeping the longitudinal rib beam 2, the transverse rib beam 3 and the foam block 4 on the same plane;

[0067] Step B5: laying the floor heating pipe 6 on the upper surfaces of the longitudinal rib beam 2, the transverse rib beam 3 and the foam block 4;

[0068] Step B6: Direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com