Building spoil drying device for ceramsite production

A construction spoil and drying device technology, which is applied in the production of ceramic materials, drying, dryers, etc., can solve the problems of insufficient drying of construction spoil, failure of stirring rods to stir construction spoil, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

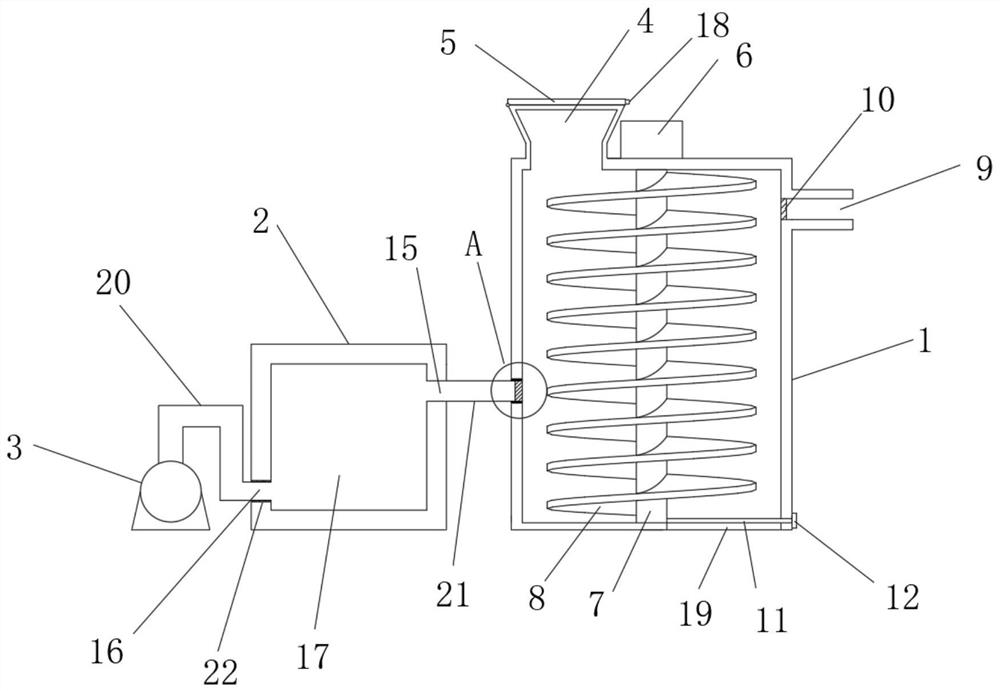

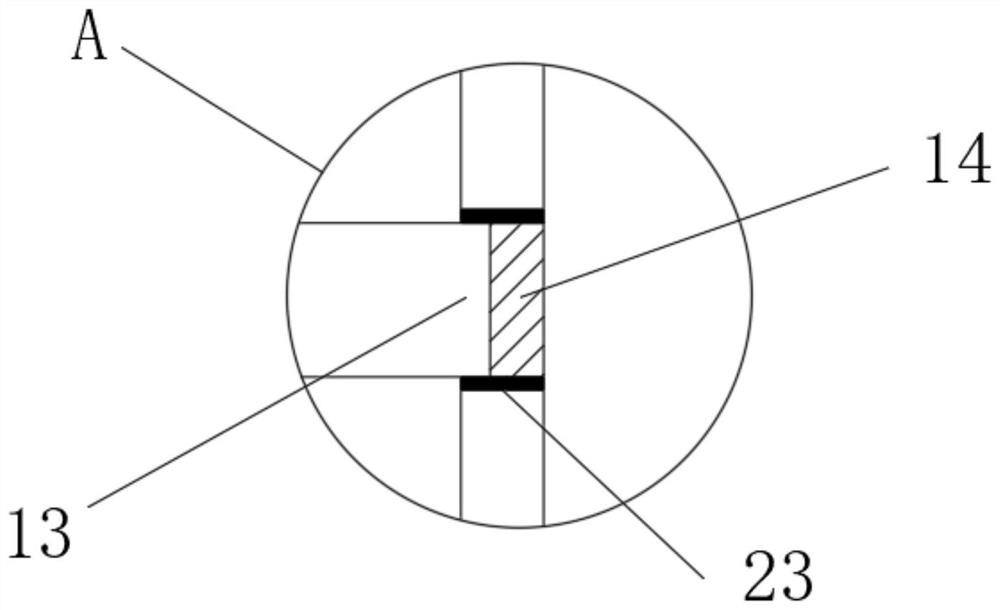

[0022] A construction waste soil drying device for ceramsite production. In order to solve the problem that most of the construction waste soil drying devices for ceramsite production on the market currently use conical containers to hold construction waste soil, there is a lot of space to waste, and the stirring rod The building spoil at the bottom cannot be stirred, so that the building spoil at the bottom cannot be fully dried, and the resulting building spoil does not meet the requirements for making ceramsite. As a preferred embodiment, such as figure 1 with figure 2 As shown, it includes a drying chamber 1 and a cold air heating chamber 2. The top of the drying chamber 1 is provided with a construction spoil feed port 4, and a cover 5 is installed on the top of the construction spoil feed port 4, and one side of the cover 5 is provided There is a handle 18, a motor 6 is arranged on the right side of the building spoil feed port 4, a rotating shaft 7 is installed inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com