Test method for simulating tunnel to pass through columnar jointed rock mass

A technology of columnar joints and test methods, applied in the direction of applying stable tension/compression to test material strength, preparation of test samples, and measurement devices, etc., can solve the problems of poor overall mechanical properties, complex mechanical properties of tunnel surrounding rock, tunnel surrounding Rock stress redistribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

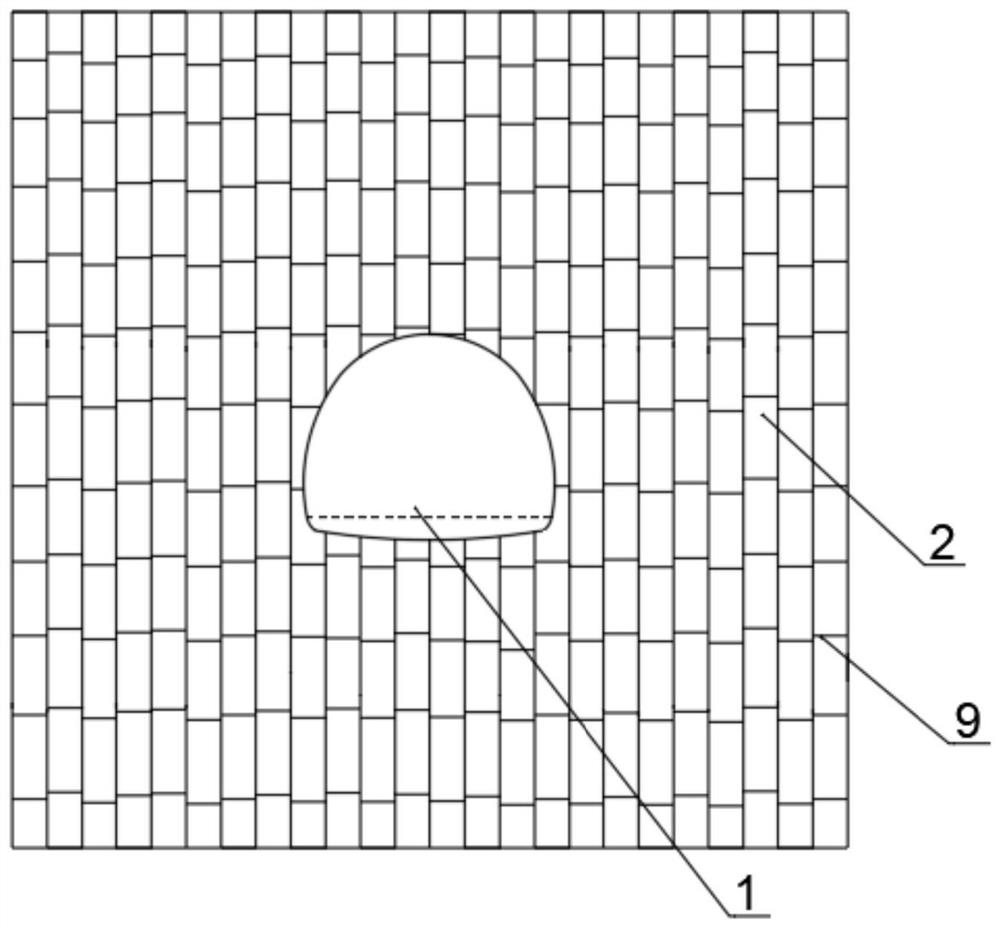

[0049] Such as Figure 1 to Figure 12 As shown in Fig. 1, a test method for simulating a tunnel passing through a columnar jointed rock mass, including making a columnar jointed rock mass model, tunnel excavation, tunnel load pressurization, and data monitoring of displacement and stress.

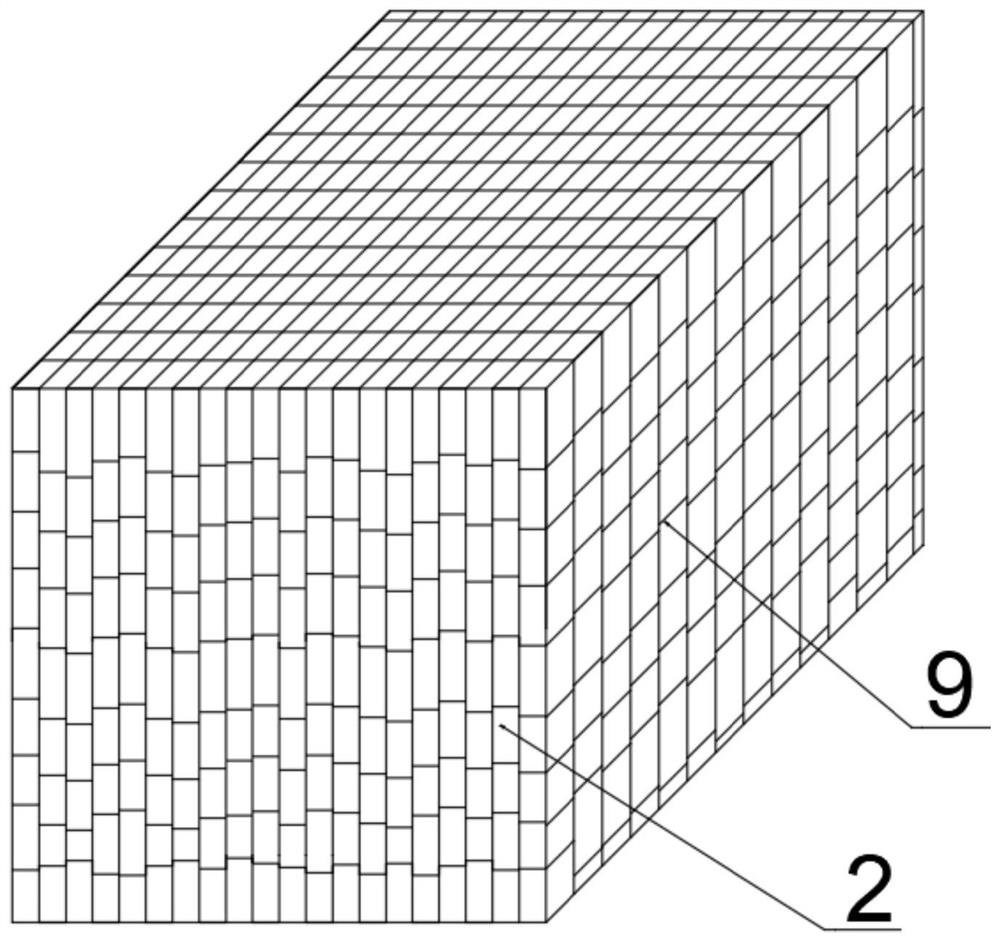

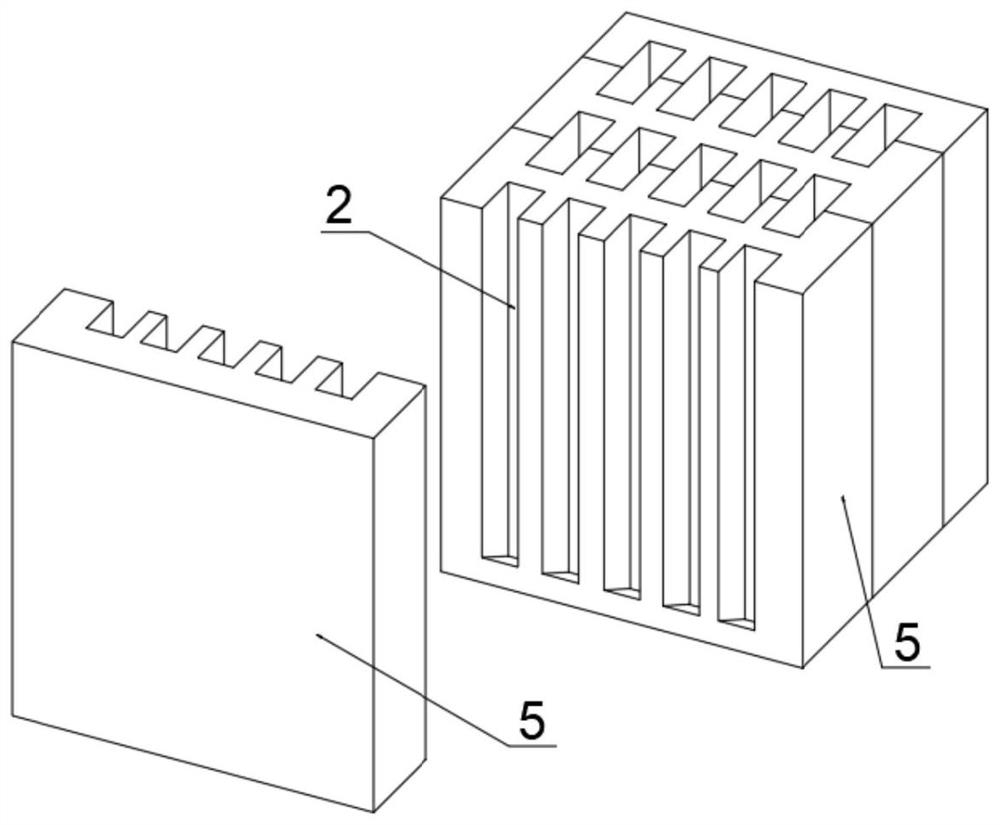

[0050] Firstly, the columnar joint rock mass model is made. Choose colorless plexiglass plates 5 to splice into a square prism mold with an overall cross-sectional size of 1m×1m, such as image 3 As shown, the material for making the columnar joint rock mass model is a mixture of water and lime in a certain proportion. According to the actual engineering situation, gypsum with different strengths is made by adjusting the water-cement ratio to simulate rock models under different surrounding rock grades. The rock models made are spliced with shale fillers, which form the rock model structure surface 9, thereby further making the columnar rock mass model. In this embodiment, the shale fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com