Three-dimensional coil coefficient calibration method based on optical pump nuclear magnetic resonance

A coil coefficient and nuclear magnetic resonance technology, which is applied in the direction of magnetic resonance measurement, magnetic variable measurement, etc., can solve problems such as calibration, large calibration error accuracy, and the size and shape of the magnetometer probe cannot be placed in the center of the coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

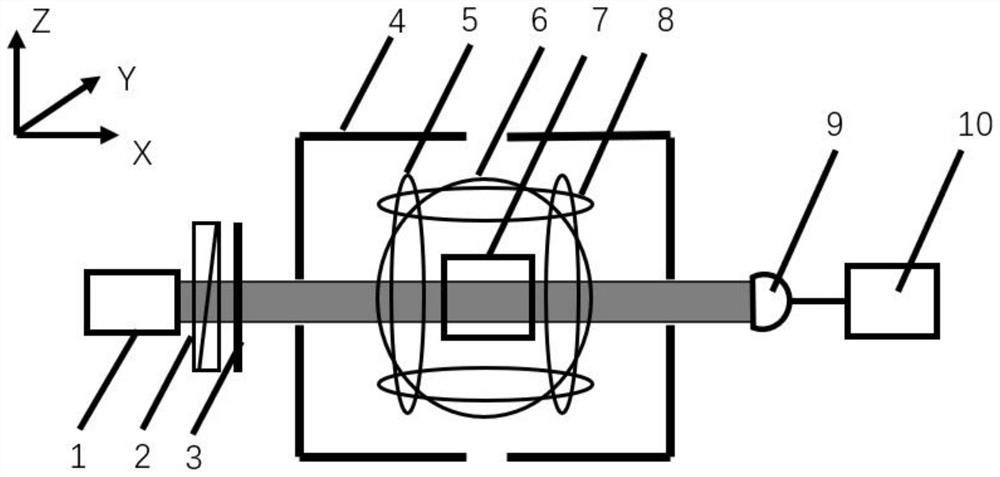

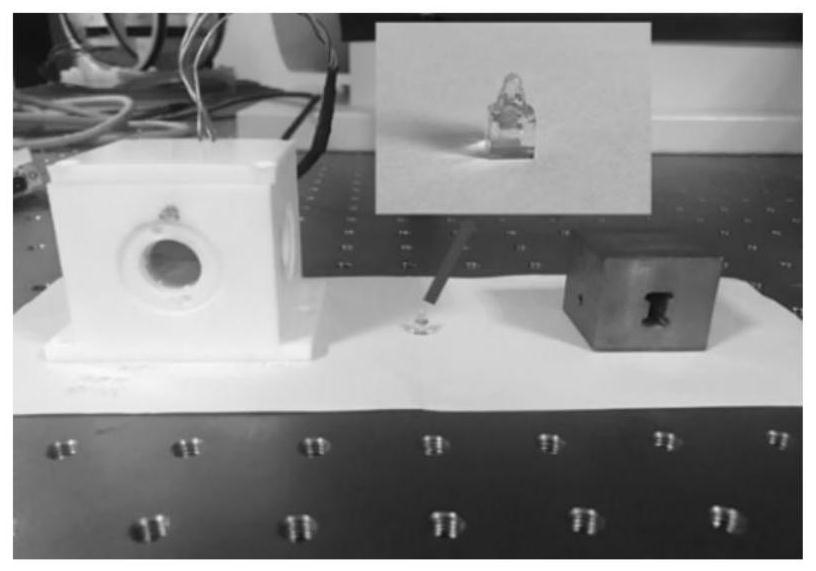

[0015] Such as Figure 1 ~ Figure 3 As shown, this embodiment relates to a three-dimensional coil coefficient calibration device based on optical pump nuclear magnetic resonance, including: a pump laser light source 1, a linear polarizer 2, and a λ / 4 wavelength optical lens that are sequentially arranged on the side of the magnetic shielding cylinder 4 3, and the photodetector 9 and the lock-in amplifier 10 arranged in turn on one side of the magnetic shielding cylinder 4, wherein: the three-dimensional Helmholtz coils 5, 6, 8 are assembled from the inside to the outside and placed in the center of the magnetic shielding cylinder 4 , the cesium atom gas cell 7 is fixed in the center of the three-dimensional Helmholtz coil, the laser light generated by the pump laser source 1 is converted into left-handed circularly polarized light through the linear polarizer 2 and the λ / 4 wavelength optical lens 3 in turn, and the left-handed circularly polarized light passes through The outg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com