Split-flow treatment device for sewage treatment

A treatment device and sewage treatment technology, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of time-consuming and labor-intensive moving process, easy blockage of filter plate, increased labor intensity of staff, etc., to reduce labor intensity , the effect of preventing filter hole clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

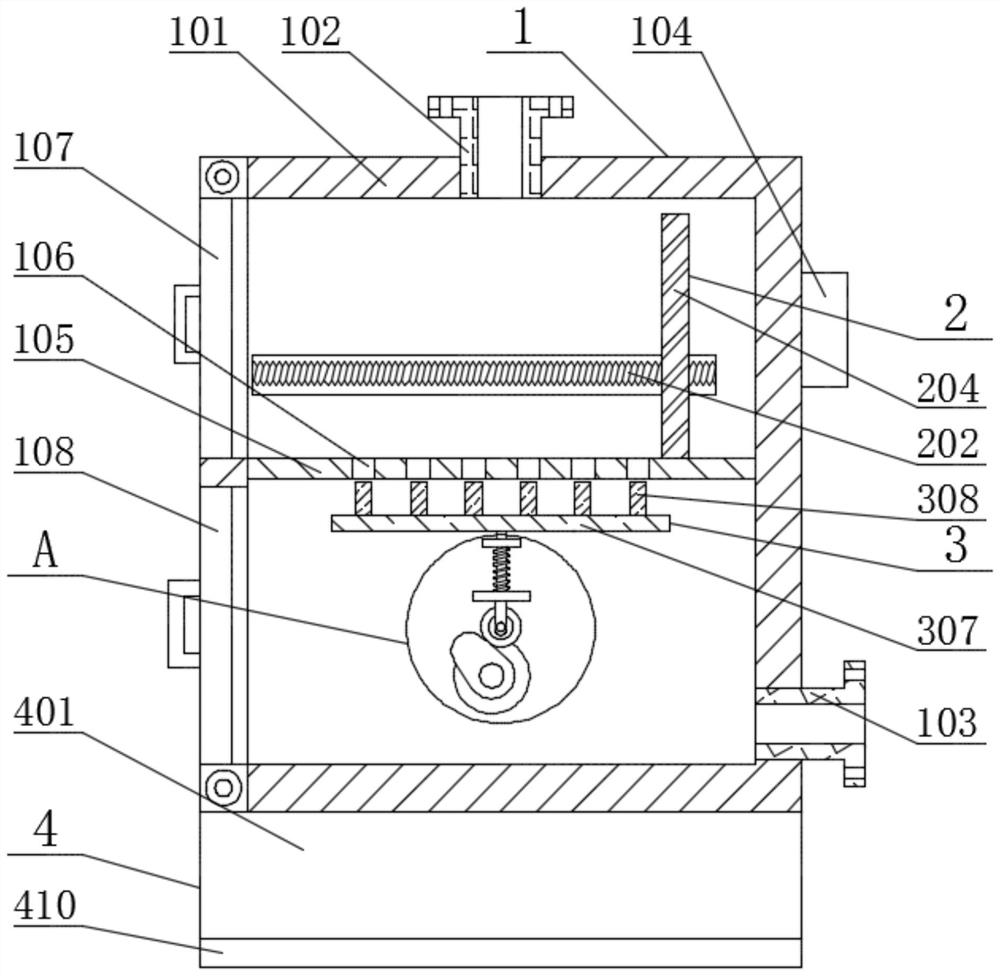

[0033] see figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

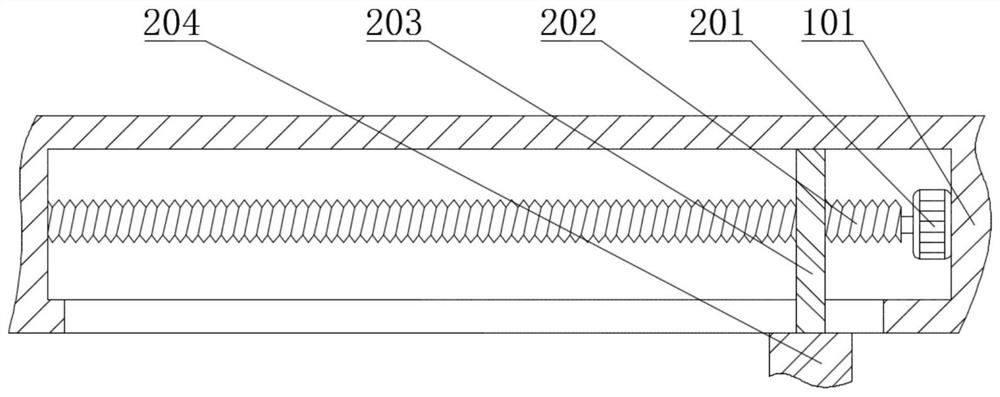

[0034]A diversion treatment device for sewage treatment, comprising a main device 1, a pushing device 2, a cleaning device 3 and a moving device 4, the main device 1 includes a diversion box 101, a controller 104 is fixedly connected to the top of the right end of the diversion box 101, and the diversion A filter plate 105 is fixedly connected to the center of the inner side of the box 101, and a filter hole 106 is opened on the filter plate 105. A first box door 107 is hinged on the top of the left end of the splitter box 101, and a second box door is hinged on the bottom of the left end of the splitter box 101. 108. The pushing device 2 includes a first motor 201, the first motor 201 is fixedly connected to the splitter box 101, the end of the main shaft of the first motor 201 is fixedly connected to a first threaded shaft 202, and the first threa...

Embodiment 2

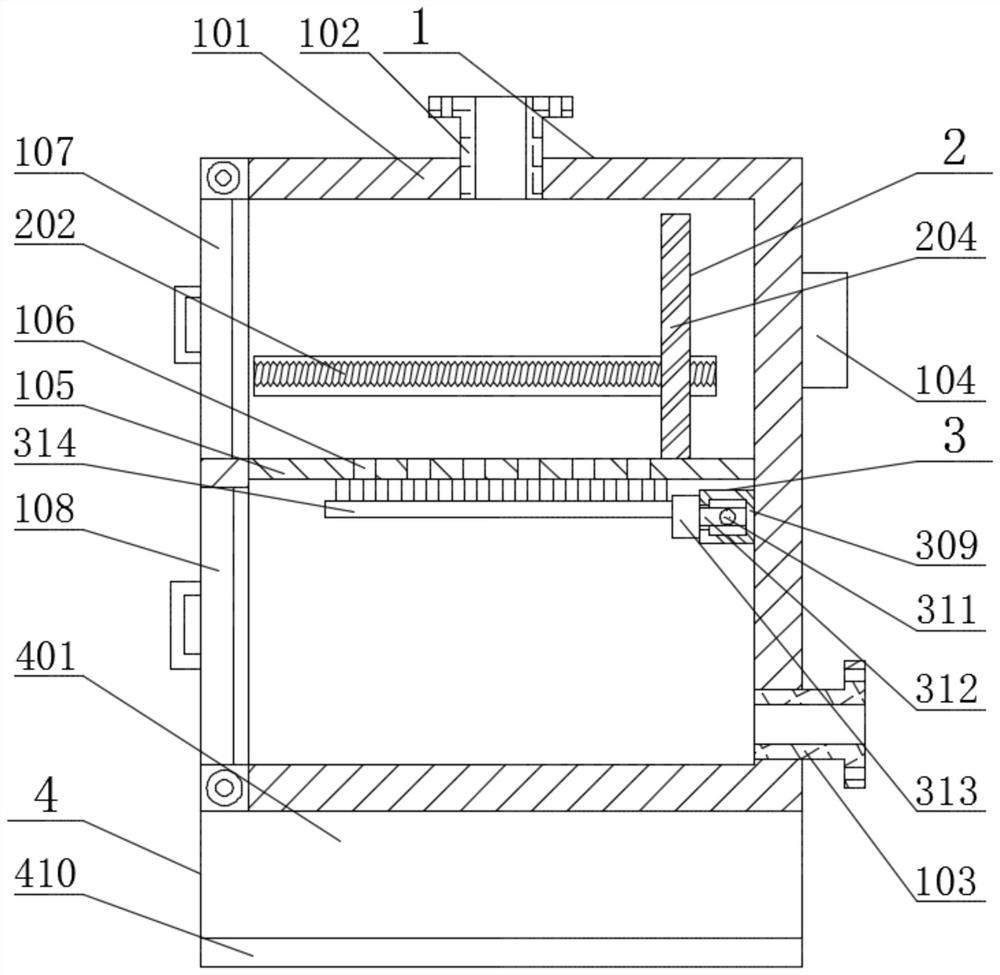

[0038] In embodiment 2, the same part as in embodiment 1 will not be repeated, please refer to the different parts figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0039] The cleaning device 3 includes a fixed plate 309 and a cleaning brush 314, the fixed plate 309 is fixedly connected with the splitter box 101, the inner side of the front end of the fixed plate 309 is fixedly connected with a third motor 310, and the end of the main shaft of the third motor 310 is fixedly connected with a second threaded shaft 311, the second threaded shaft 311 is rotationally connected with the fixed plate 309, the second threaded shaft 311 is spirally connected with the second slider 312 outside, the second slider 312 runs through the fixed plate 309, and the second slider 312 is slidably connected with the fixed plate 309 , the outer side of the second slider 312 is fixedly connected with a connecting block 313, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com