Graphite spheroidizing and crushing device for lithium batteries and processing method

A crushing device and technology of graphite balls, which are applied in chemical instruments and methods, solid separation, filtration, etc., can solve the problems of high tap density, unreachable tap density, sharp edges and corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

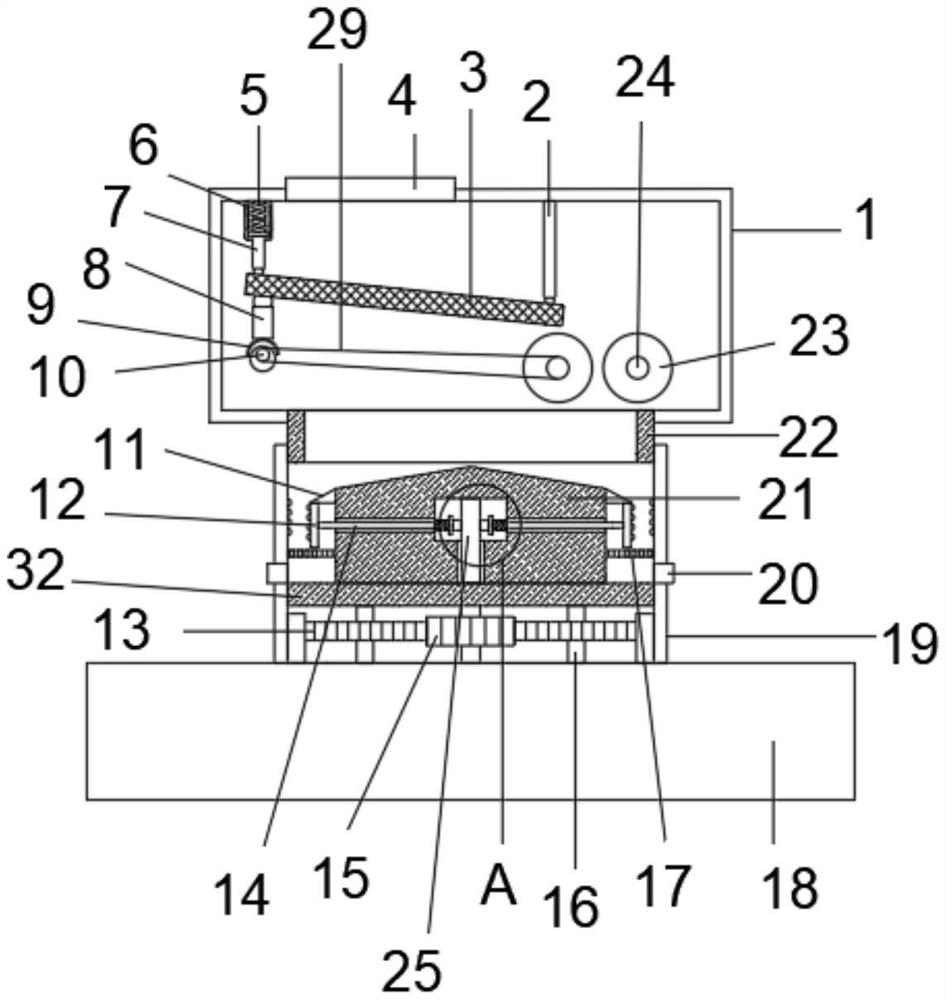

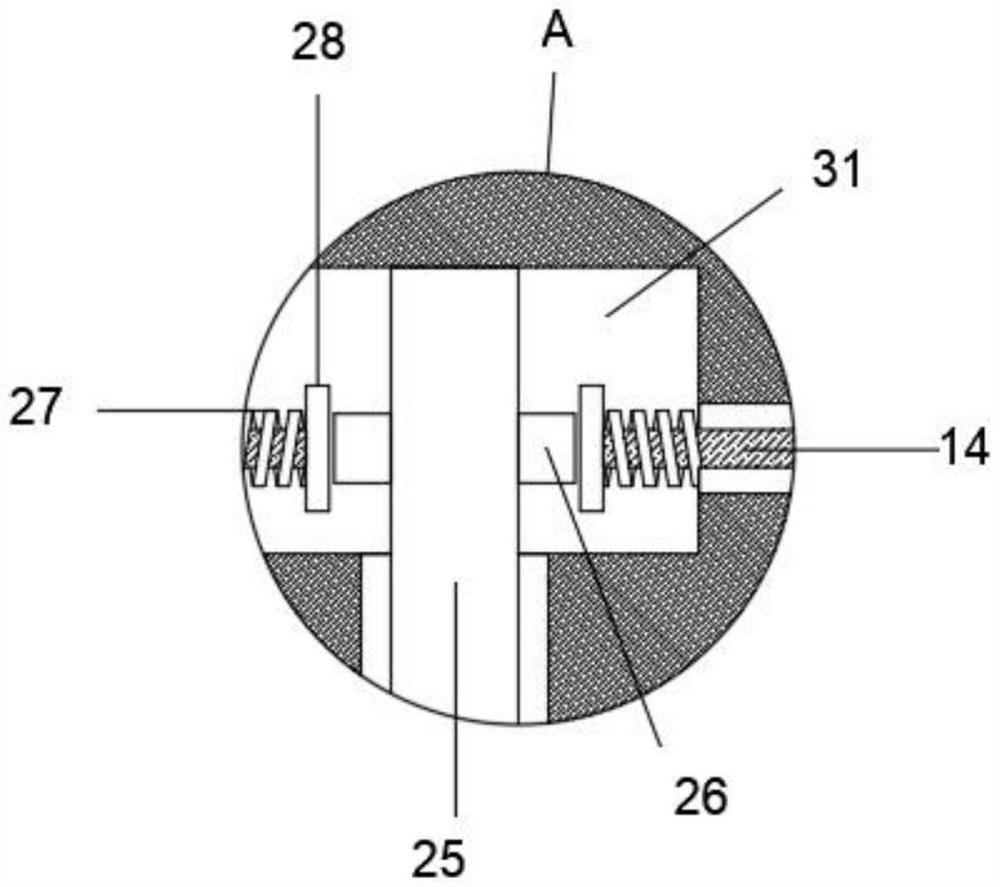

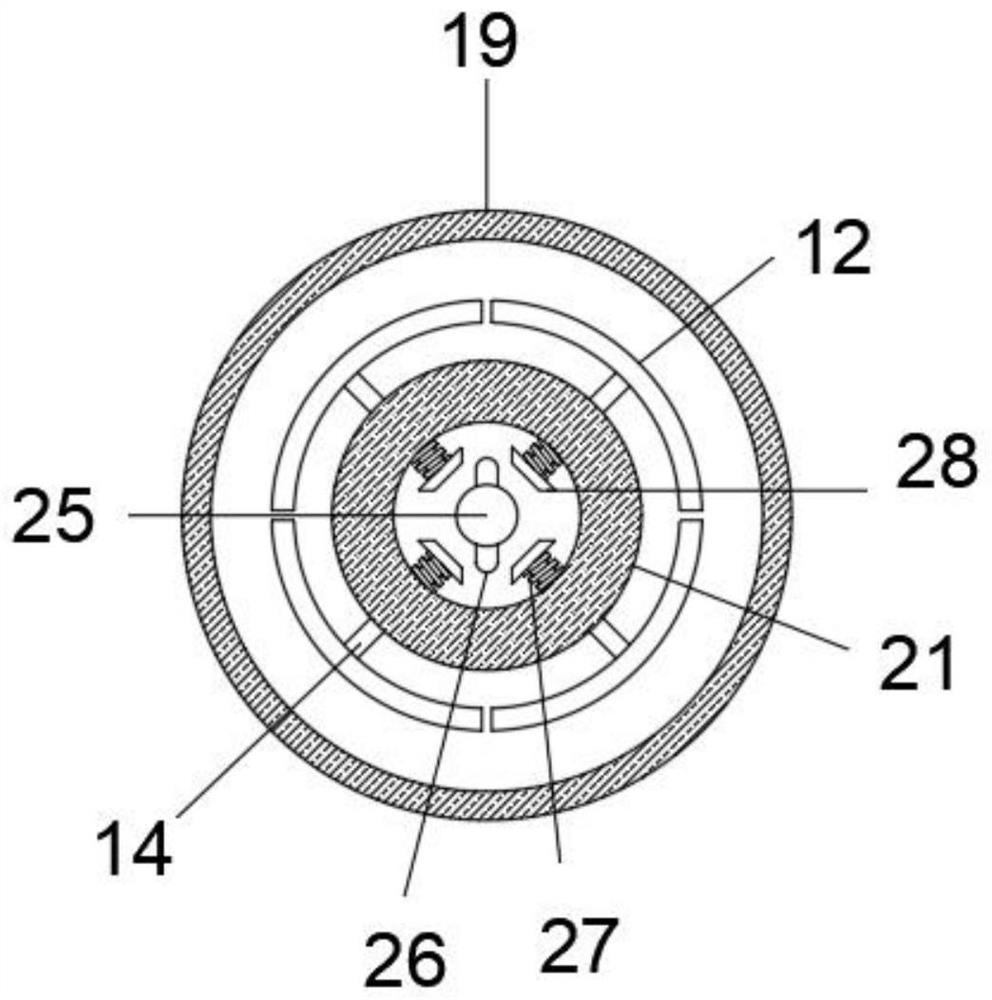

[0030] refer to Figure 1-4 , a graphite spheroidizing device for a lithium battery, comprising a base 18, the base 18 is rotatably connected with a drum 19, the drum 19 is rotatably connected with a partition 32, and the partition 32 is fixedly connected with a fixed block 21, the fixed block 21 is sleeved with a mesh plate 17, and the mesh plate 17 is slidably connected to the drum 19. The mesh plate 17 can filter particles of acceptable size, and the oversized graphite particles remain on the upper end of the mesh plate 17 for repeated grinding. The fixed block 21 One end away from the dividing plate 32 is conically arranged, and the slide plate 11 is set in a cir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap