Plastic packaging press

A technology of a press and a first flow channel, applied in the field of plastic sealing presses, can solve the problems of a large number of air bubbles and the inability of the plastic sealing material to fill the mold hole air, etc., and achieve the effects of reducing air bubbles, facilitating cleaning, and improving the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The following will be further described in detail below with reference to specific embodiments:

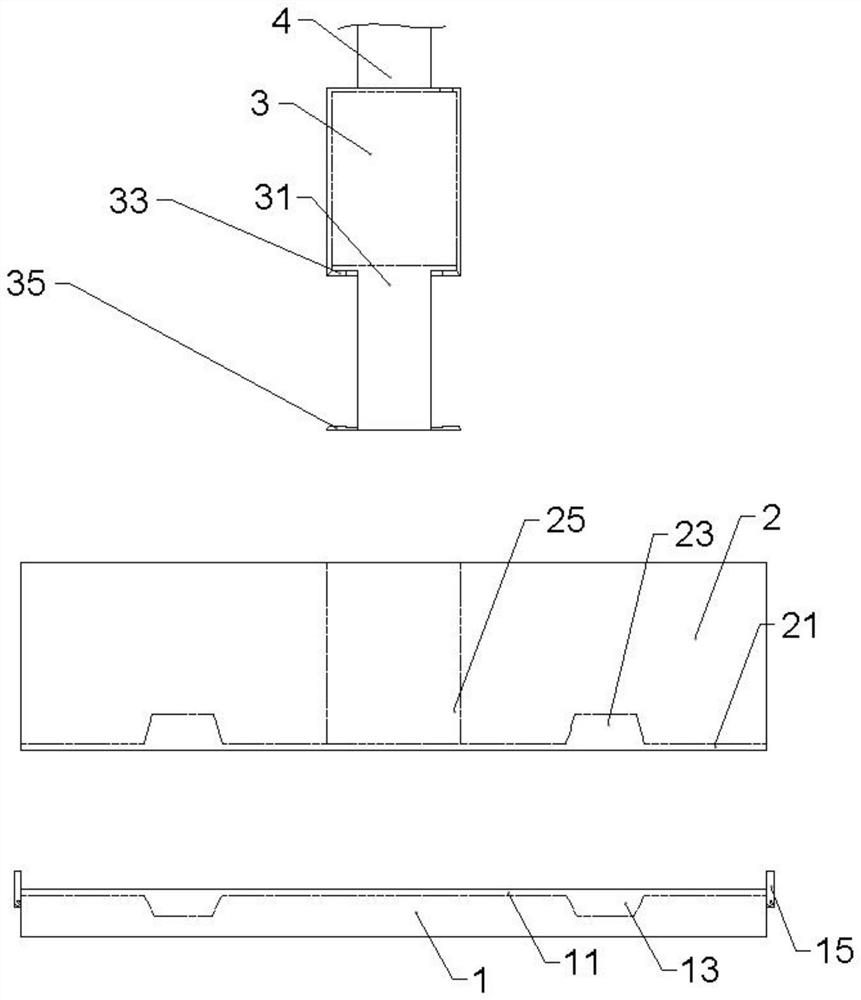

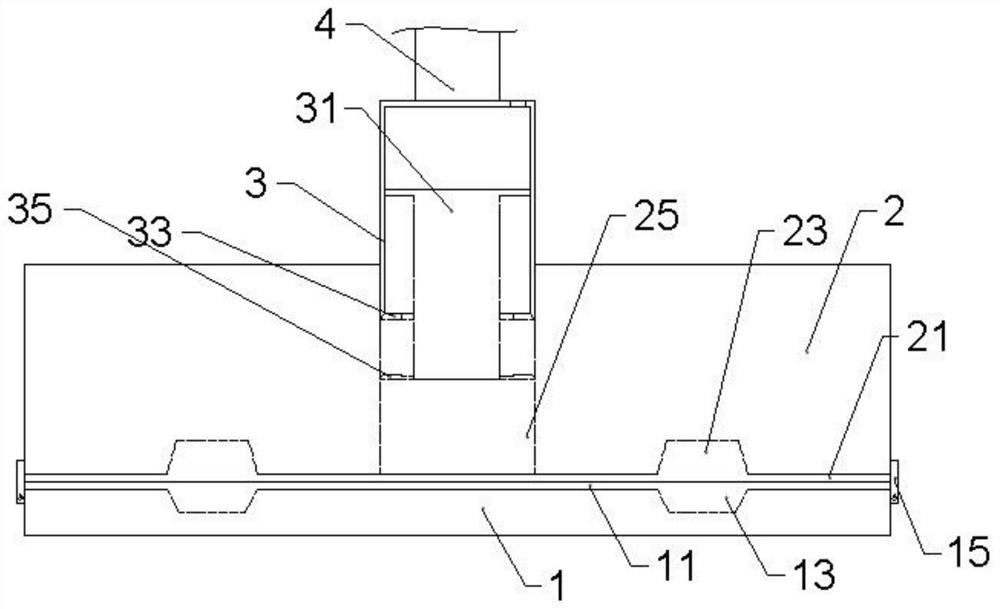

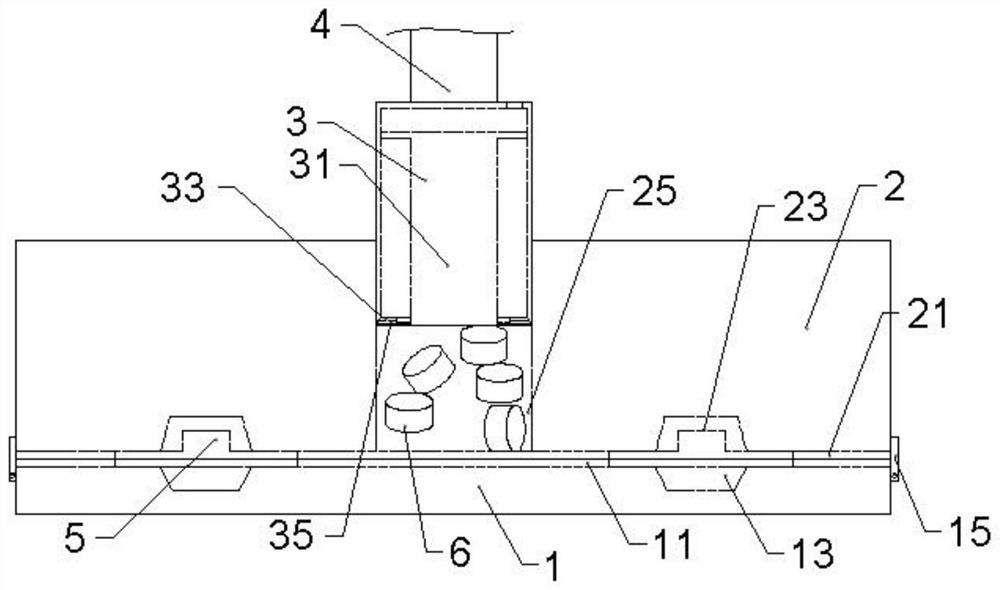

[0022]Reference numerals in the accompanying drawings include: supporting lower mold 1, first flow path 11, first placed hole 13, baffle 15, second flow channel 21, upper mold 2, second placement hole 23, feed channel 25 The second through hole 33, the injection rod 31, the outer casing 3, the blade 35, the drive rod 4, the wafer 5, and the plastic seal 6.

[0023]Embodiments are basicallyfigure 1 As shown: a plastic sealing machine, including a rack (not shown) and a plastic seal structure, the plastic structure from the bottom, in turn, the upper mold 1, upper mold 2, heating mechanism (not shown) and The injection head is fixed to the rack, and the upper mold 2 is slidably connected to the frame, and the upper mold 2 can be pressed on the support lower mold 1, and the upper surface of the upper surface 1 is opened with the first placement hole 13 and in communication. The first flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com