Connecting method of prefabricated box girder and transition layer and prefabricated box girder structure

A connection method and transition layer technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as cracks, and achieve the effects of increasing durability, increasing friction, and enhancing shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for connecting the prefabricated box girder and the transition layer of the present application comprises the following steps:

[0028] (1) Binding the main reinforcement of the box girder;

[0029] (2) After the binding of the main steel bars of the box girder is completed, a plurality of hook steel bars are arranged on the top of the main steel bars of the box girder, and the tops of the multiple hook steel bars pass through the top plate of the box girder and penetrate into the transition layer;

[0030] (3) Install the formwork, pour the concrete, and ensure its compactness. After the pouring is completed, ensure that the curing is in place. After the initial setting of the pouring is completed, the surface of the mortar is roughened to increase the friction between it and the transition layer.

[0031] Specifically, the tops of multiple hook steel bars exceed the top plate of the box girder by 5cm and extend into the transition layer to enhance the conne...

Embodiment 2

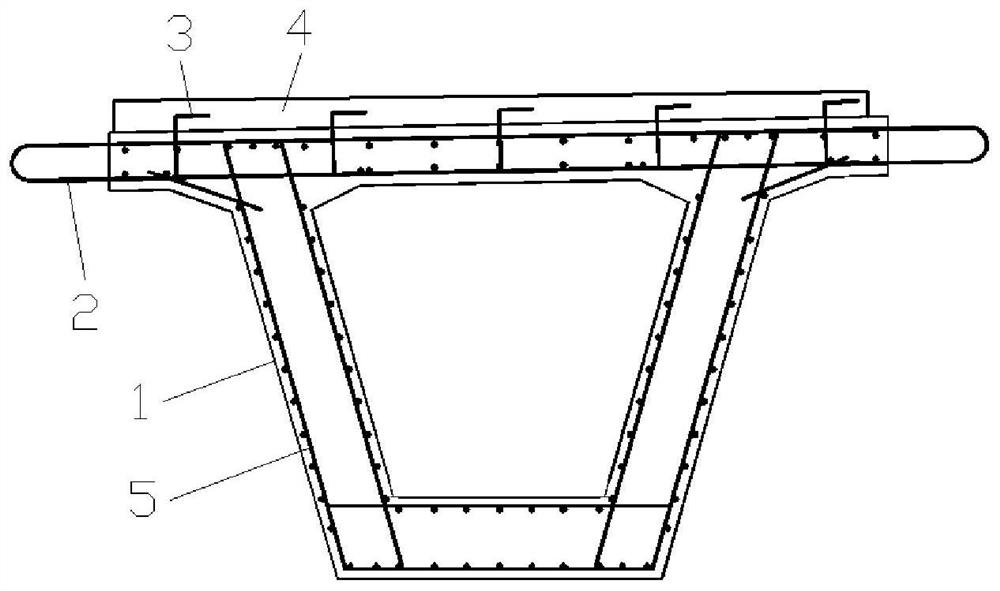

[0034] Such as figure 1 - figure 2 As shown, the prefabricated box girder structure provided in the second embodiment includes a box girder main body 1, a box girder top plate 2, a plurality of hooks 3 and a transition layer 4, and the box girder main body 1 is embedded with box girder main steel bars 5, The box girder top plate 2 is installed above the box girder main body 1, the surface of the box girder top plate 2 is brushed, the transition layer 4 is arranged on the box girder top plate 2, the bottoms of a plurality of hooks 3 are connected with the top of the box girder main steel bar 5, and many The top of each hook 3 passes through the top plate 2 of the box girder and penetrates into the transition layer 4, thereby enhancing the connection effect and firmness of the transition layer 4 and the main body 1 of the box girder.

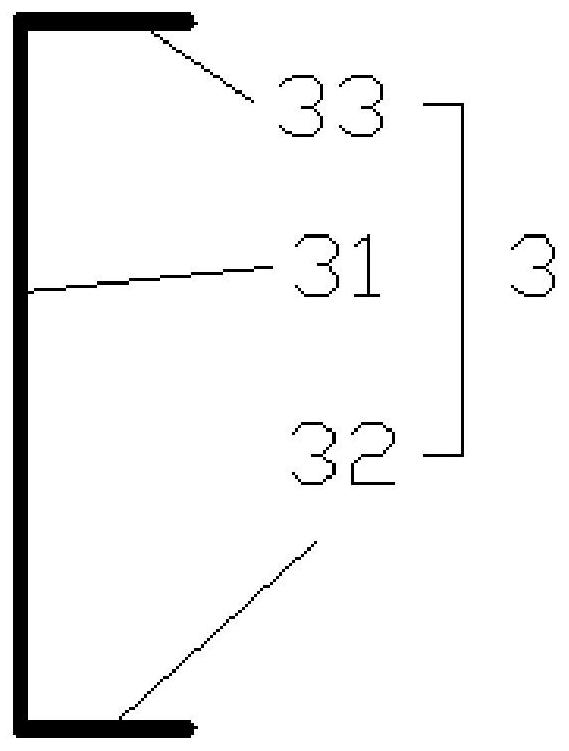

[0035] Specifically, the crotch member 3 includes a rod body 31, a first crotch 32 and a second crotch 33, the rod body 31 is vertically arrang...

Embodiment 3

[0037] The prefabricated box girder structure provided in the third embodiment is a further improvement on the prefabricated box girder structure provided in the second embodiment. figure 1 - figure 2 On the basis of , the prefabricated box girder structure provided in Example 3 includes a box girder main body 1, a box girder top plate 2, a plurality of hooks 3 and a transition layer 4, and box girder main body 1 is embedded with box girder main steel bars 5 , the box girder top plate 2 is installed above the box girder main body 1, the surface of the box girder top plate 2 is brushed, the transition layer 4 is arranged on the box girder top plate 2, and the bottoms of a plurality of hooks 3 are connected to the top of the box girder main steel bar 5, The tops of the plurality of hooks 3 pass through the top plate of the box girder 2 and go deep into the transition layer 4, thereby enhancing the connection effect and firmness of the transition layer 4 and the main body 1 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com