Mud-sealed rock mass supporting method suitable for argillization rock

A shale rock and sludge technology, applied in the field of mining equipment, can solve the problems of difficult support work, unfavorable continuous shotcrete operation and safe operation, serious physical energy consumption of human body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

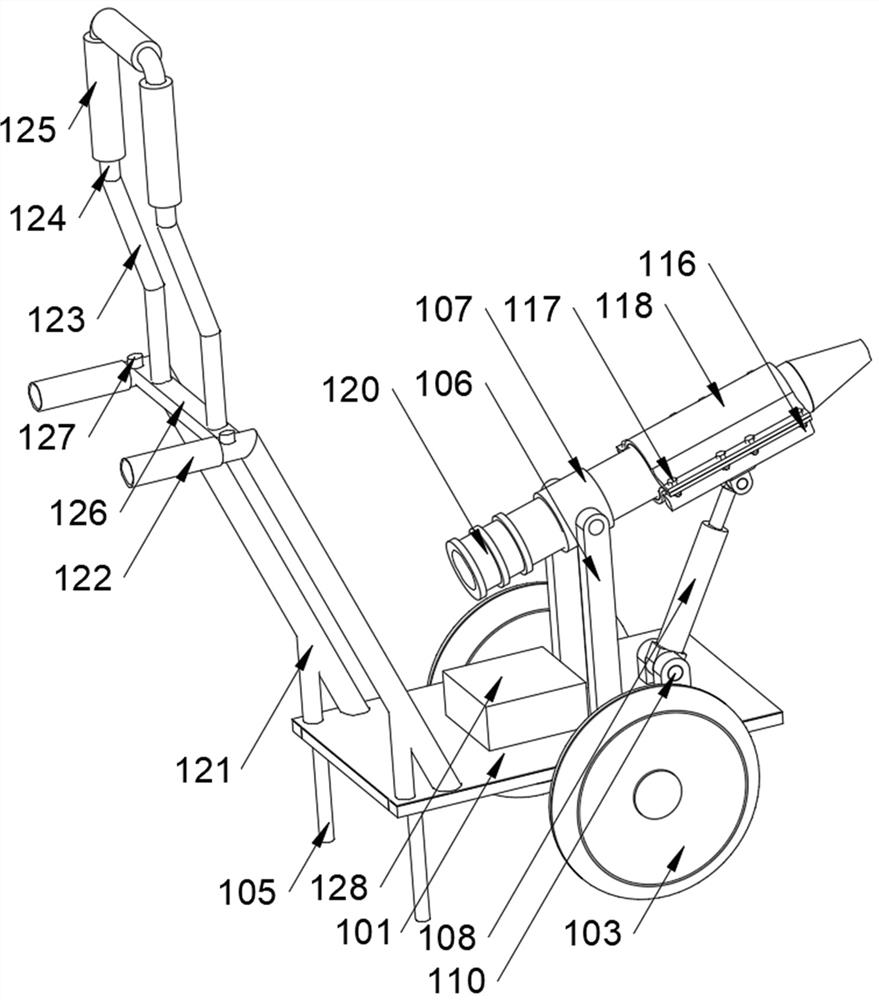

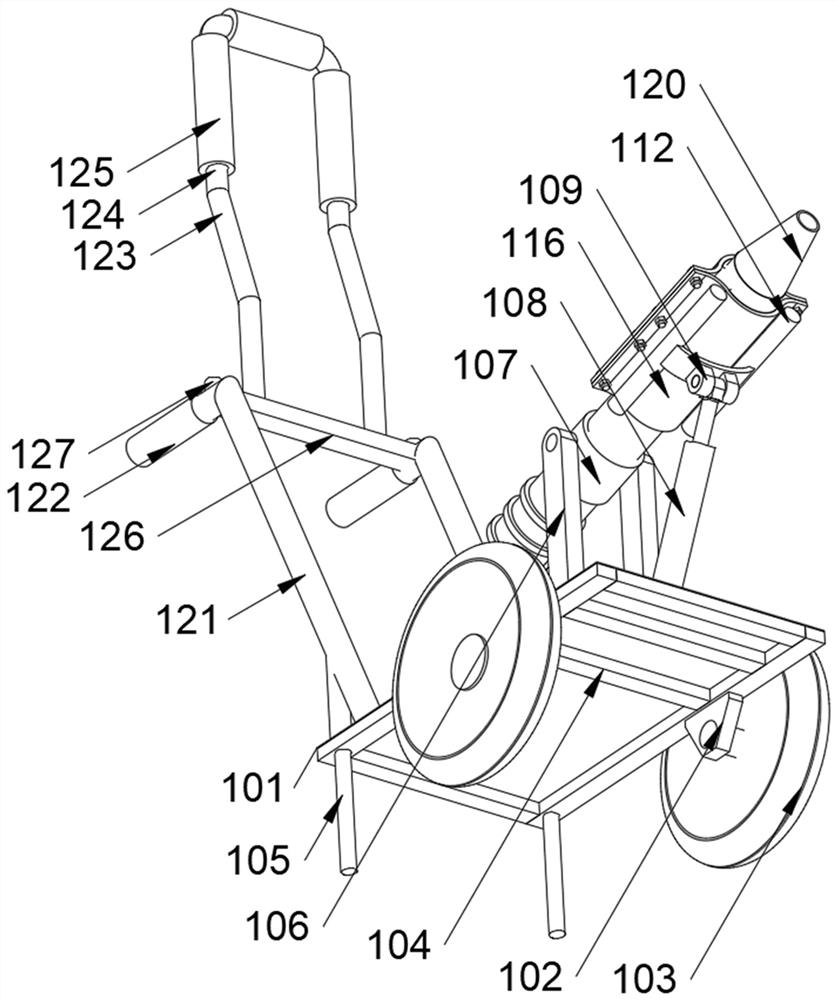

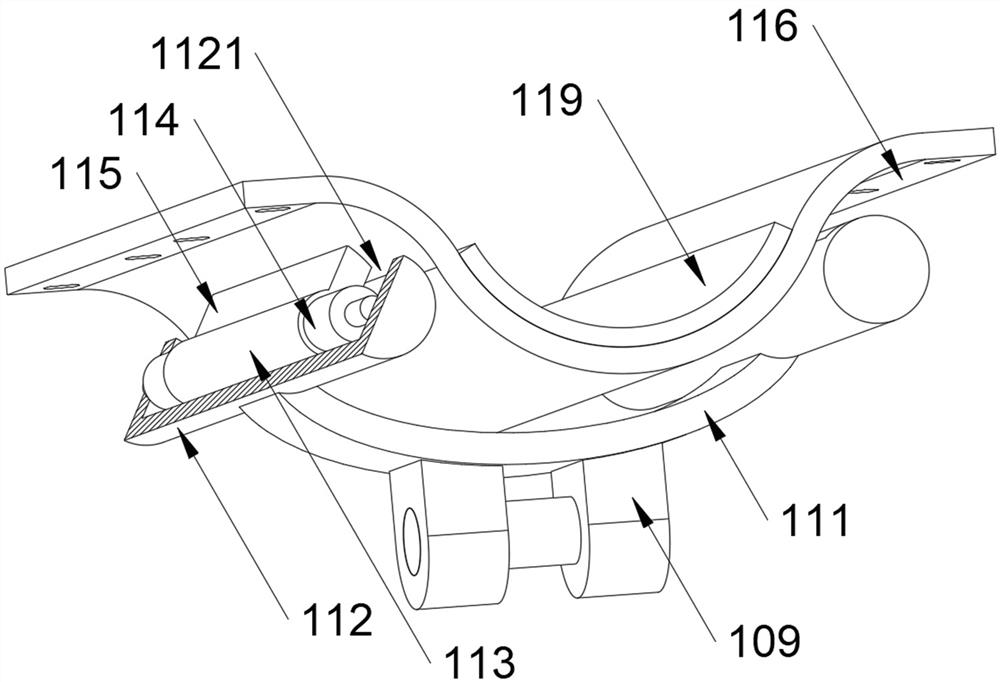

[0029] see Figure 1-Figure 3, the present invention provides the following technical solutions: a mud-sealed rock support method suitable for argillaceous rocks, including a walk-behind spraying mechanism 1, and the walk-behind spraying mechanism 1 includes a bottom plate 101, and the bottom plate The left and right sides of the bottom of 101 are equipped with supporting wheels 103 through the support 102, and the top surface of the bottom plate 101 is fixedly equipped with a rear fixing seat 106 and is connected to the bottom end of the electric push rod 108 through the lower connecting seat 110. The bottom surface of the base plate 101 below the fixing seat 106, the lower connecting seat 110 and the edge of the bottom surface of the base plate 101 are welded with reinforcing ribs 104, and the rear end of the reinforcing rib 104 bottom surface is welded with a rear leg 105, and the rear support leg 105 of the rear fixing seat 106 The top end is rotatably connected to the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com