Intelligent monitoring and purifying system for exhaust emission of thermal power plant

A technology for exhaust emission and intelligent monitoring, applied in emission prevention, incinerators, chemical instruments and methods, etc., can solve problems such as damage and dangerous equipment, and achieve the effect of reducing environmental pollution and reducing personnel demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

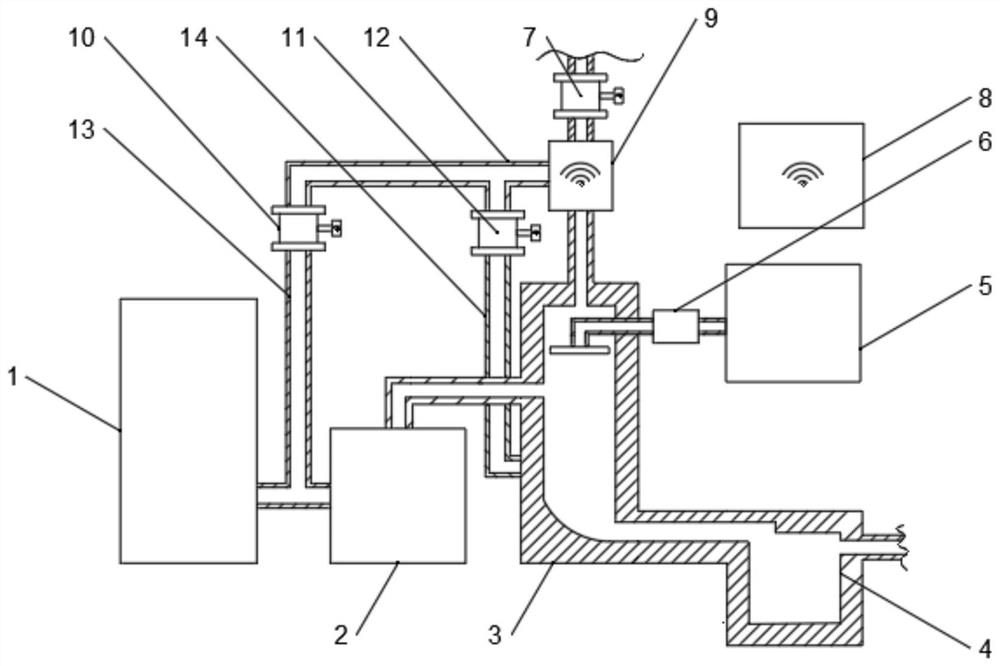

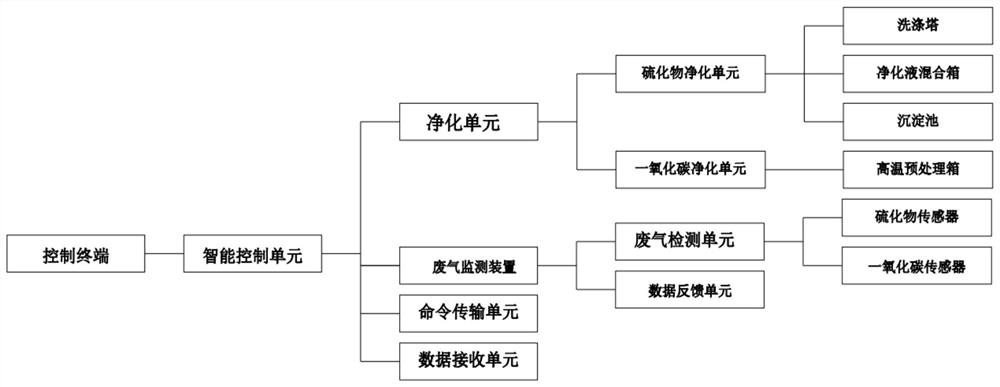

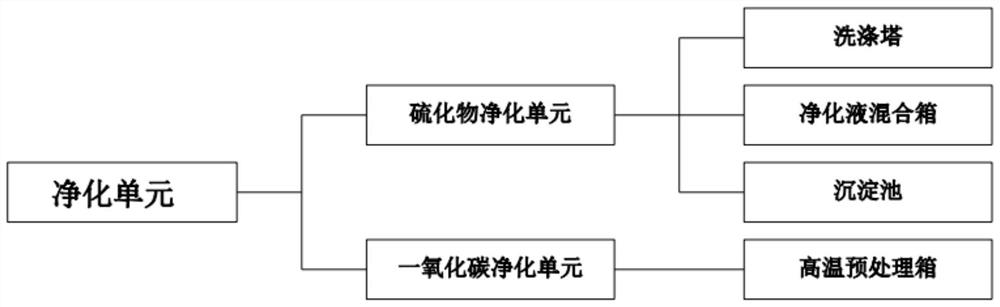

[0026] Example: such as Figure 1-4 As shown, a thermal power plant waste gas emission intelligent monitoring and purification system of the present invention includes a boiler 1 and a control terminal 8, a high-temperature pretreatment box 2 is provided on one side of the boiler 1, and a washing tower 3 is provided on one side of the high-temperature pretreatment box 2, One side of the washing tower 3 is provided with a sedimentation tank 4, and one end of the sedimentation tank 4 is provided with a purification liquid mixing tank 5, the purification liquid mixing tank 5 is connected to the washing tower 3 through pipelines, and a water pump 6 is installed between the purification liquid mixing tank 5 and the washing tower 3 , the upper end of the washing tower 3 is equipped with an exhaust gas monitoring device 9, the upper end of the exhaust gas monitoring device 9 is provided with a smoke exhaust pipe, and the third electronic valve 7 is set on the smoke exhaust pipe, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com