Method and system for collecting shrinkage rate and accuracyof product

A technology of shrinkage rate and accuracy rate, which is applied in the collection method and system field of product shrinkage rate accuracy rate, can solve the problems of prolonging product development time, increasing mold cost, and low qualified rate of mold opening size, so as to reduce product development cycle and Development cost, effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

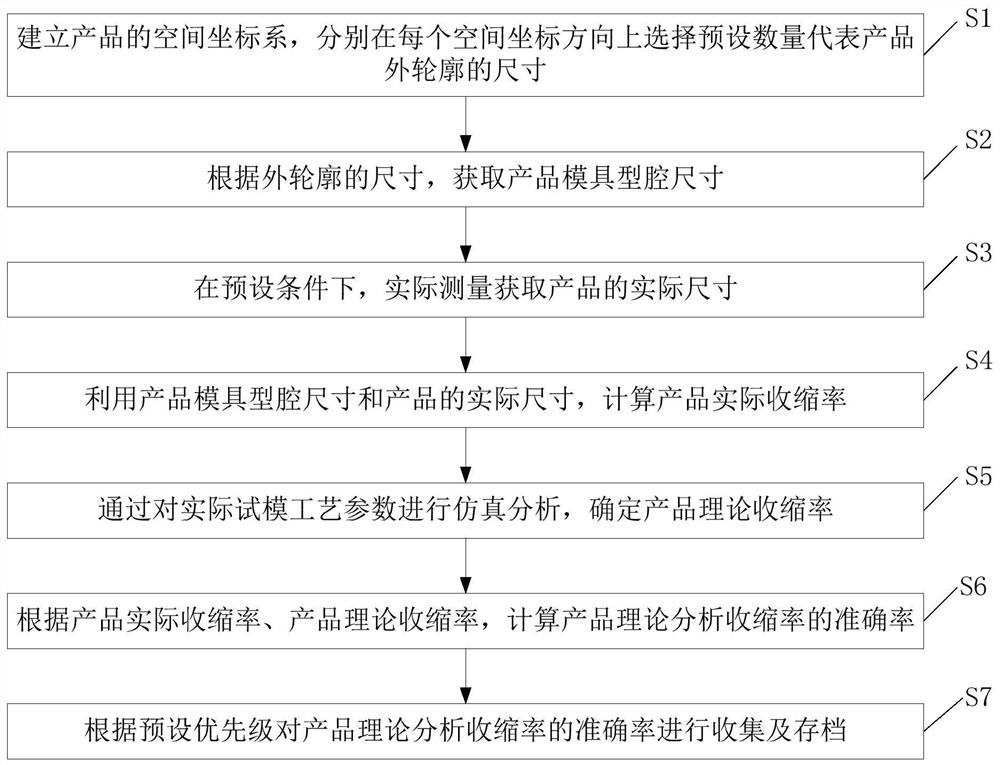

[0042] A method for collecting the accuracy of product shrinkage rate provided by an embodiment of the present invention, such as figure 1 shown, including the following steps:

[0043] Step S1: Establish a space coordinate system of the product, and select a preset number in each space coordinate direction to represent the size of the outer contour of the product.

[0044] In the embodiment of the present invention, selecting a preset number of sizes representing the outer contour of the product in each space coordinate direction includes: avoiding the warping position of the product in each space coordinate direction, and selecting at least three dimensions representing the outer contour of the product. The size of the outline is just an example and not limited thereto. In practical applications, the corresponding preset number is selected according to actual needs to represent the size of the outer outline of the product.

[0045] Step S2: According to the spatial coordina...

Embodiment 2

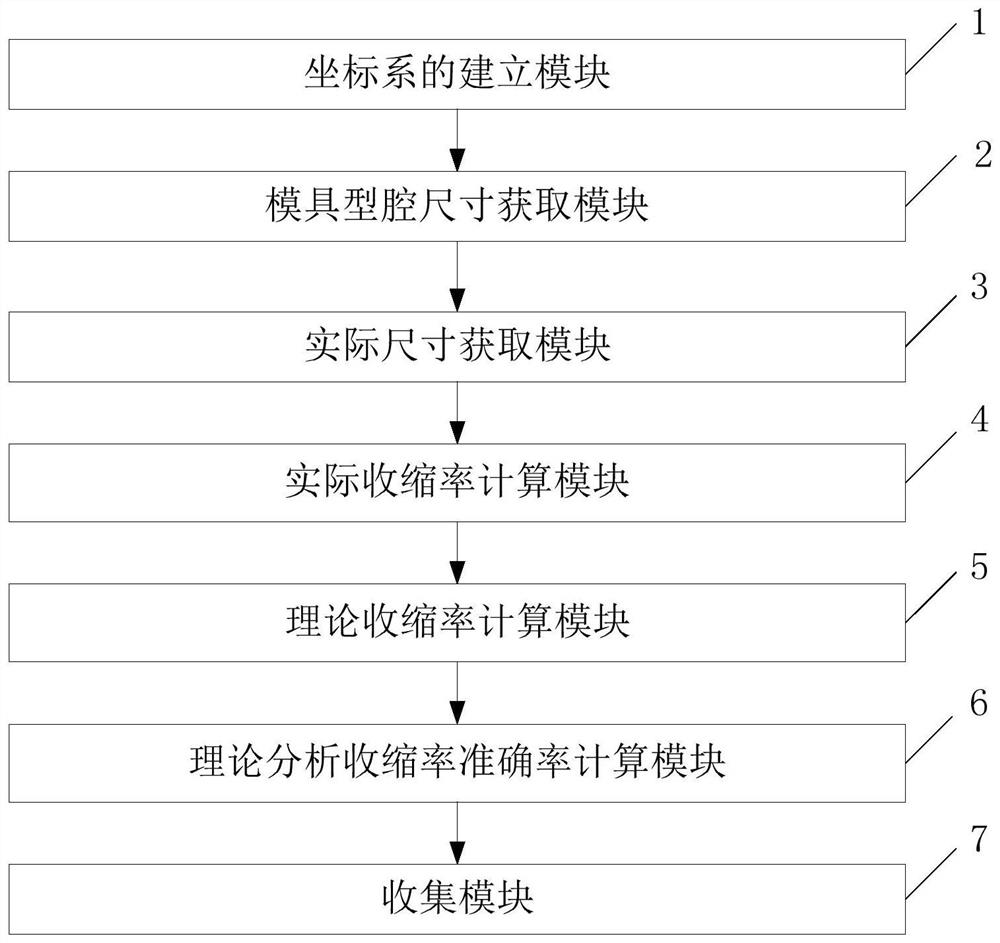

[0064] An embodiment of the present invention provides a collection system for the accuracy of product shrinkage, such as figure 2 shown, including:

[0065] The establishment module 1 of the coordinate system is used to establish the spatial coordinate system of the product, and selects a preset number to represent the size of the outer contour of the product in each spatial coordinate direction; this module executes the method described in step S1 in Embodiment 1, I won't repeat them here.

[0066] The mold cavity size obtaining module 2 is used to obtain the product mold cavity size according to the size of the outer contour; this module executes the method described in step S2 in Embodiment 1, which will not be repeated here.

[0067] The actual size acquisition module 3 is used to actually measure and acquire the actual size of the product under preset conditions; this module executes the method described in step S3 in Embodiment 1, which will not be repeated here.

[...

Embodiment 3

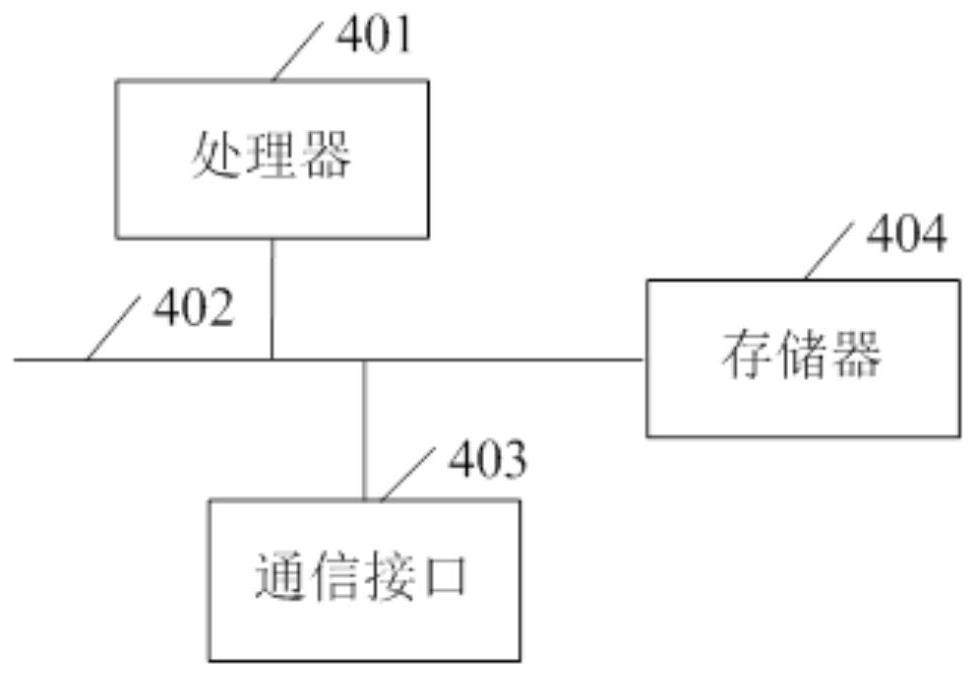

[0074] An embodiment of the present invention provides a terminal, such as image 3 As shown, it includes: at least one processor 401 , such as a CPU (Central Processing Unit, central processing unit), at least one communication interface 403 , memory 404 , and at least one communication bus 402 . Wherein, the communication bus 402 is used to realize connection and communication between these components. Wherein, the communication interface 403 may include a display screen (Display) and a keyboard (Keyboard), and the optional communication interface 403 may also include a standard wired interface and a wireless interface. The memory 404 may be a high-speed RAM memory (Random Access Memory, volatile random access memory), or a non-volatile memory (non-volatile memory), such as at least one disk memory. Optionally, the memory 404 may also be at least one storage device located away from the aforementioned processor 401 . Wherein, the processor 401 may execute the method for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com