A Simulation Method Considering Non-Uniformly Distributed Root Cracks

A technology of non-uniform distribution and simulation method, applied in design optimization/simulation, instrument, geometric CAD, etc., can solve the problems of insignificant dynamic response of a single slice tooth, unable to accurately simulate the effect of meshing force, etc., and achieve accurate theoretical guidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

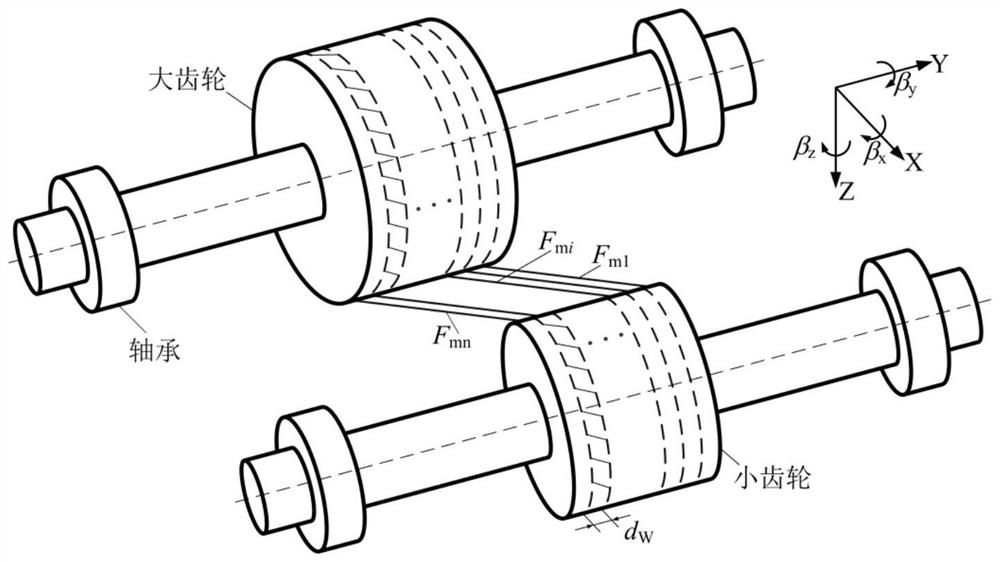

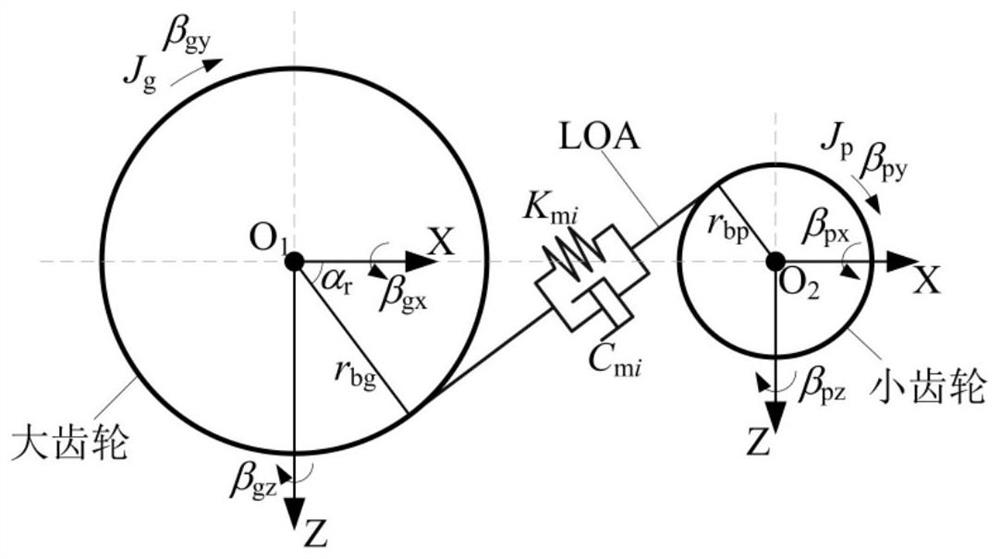

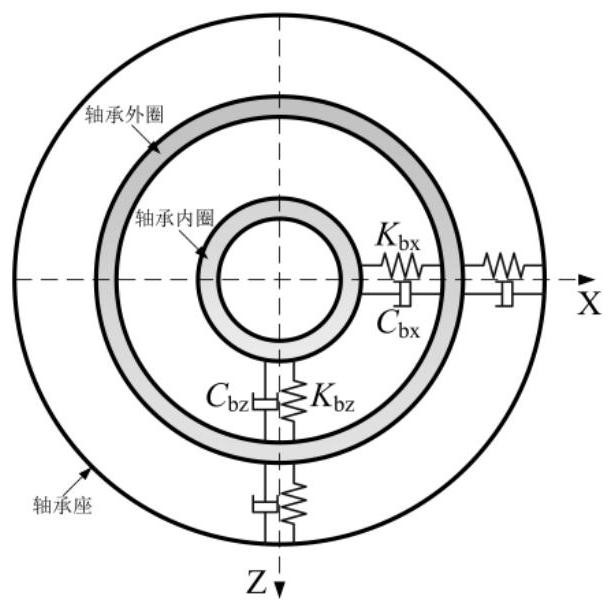

[0041] figure 1 A dynamic model of a gear transmission system under non-uniformly distributed root crack excitation of an exemplary embodiment of the present invention is shown, in this model, the prescribed positive directions of the longitudinal, transverse, vertical, roll, nod, and yaw degrees of freedom are as follows: figure 1 shown; bearing mass M b Focusing on the center of mass of the object, the big and small gears and the shaft are regarded as a whole, and its mass M g \M p and moment of inertia J g \J p All are concentrated on the center of mass of the gear. The gear meshing, the contact between the inner and outer rings of the bearing, and the contact between the outer ring of the bearing and the bearing seat are equivalent to spring-damping units, regardless of the rotation and revolution of the rolling elements inside the bearing and their dynamic interactions with the cage and the inner and outer rings. , and assume that the meshing force of each slicing too...

Embodiment 2

[0088] The design parameters of the gears to be simulated in the gear transmission system are shown in Table 1:

[0089] Table 1 Gear design parameters

[0090]

[0091] Further, for the current usage of the gear to be simulated (including the age of the gear, the application environment, etc.: the smaller the crack depth of the gear with a short service life, the larger the crack depth and length of the gear with complex working environment and large environmental vibration). According to the evaluation results, set the crack parameters of the gear to be simulated (including: crack length, crack depth, crack angle), collect the design parameters of the current gear to be simulated, and substitute the design parameters and crack parameters into In the dynamic equation of the gear transmission system based on the sliced teeth, the dynamic response of the current gear to be simulated is obtained by solving. In this example, the relevant crack parameters are: the crack dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com