Self-cleaning type dust removal system of dust collector for smart home

A technology of smart home and dust removal system, applied in vacuum cleaners, suction filters, household appliances, etc., can solve the problems of fan resistance, motor damage of fans, and reduced ventilation effect of cloth bags, so as to achieve good ventilation and prevent clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

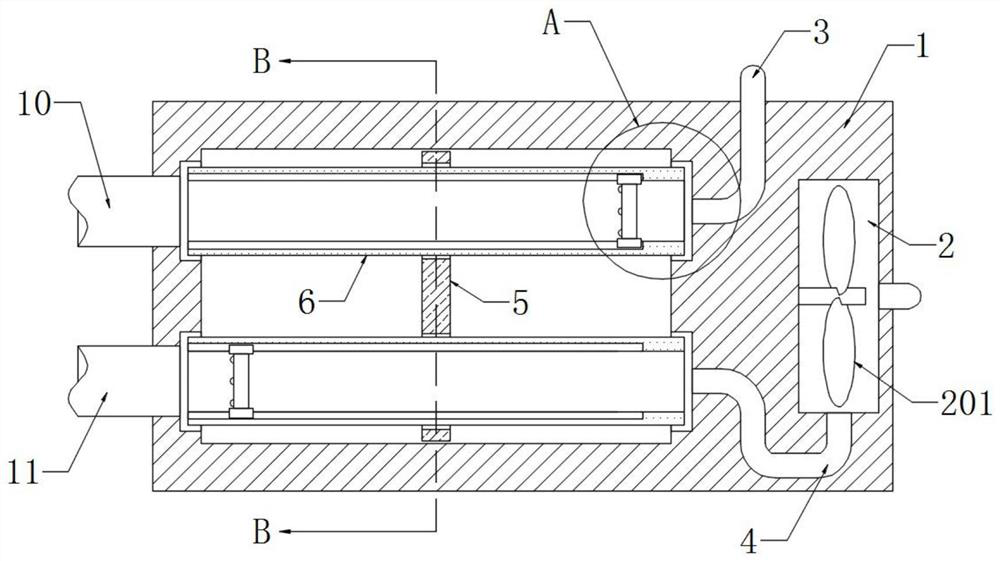

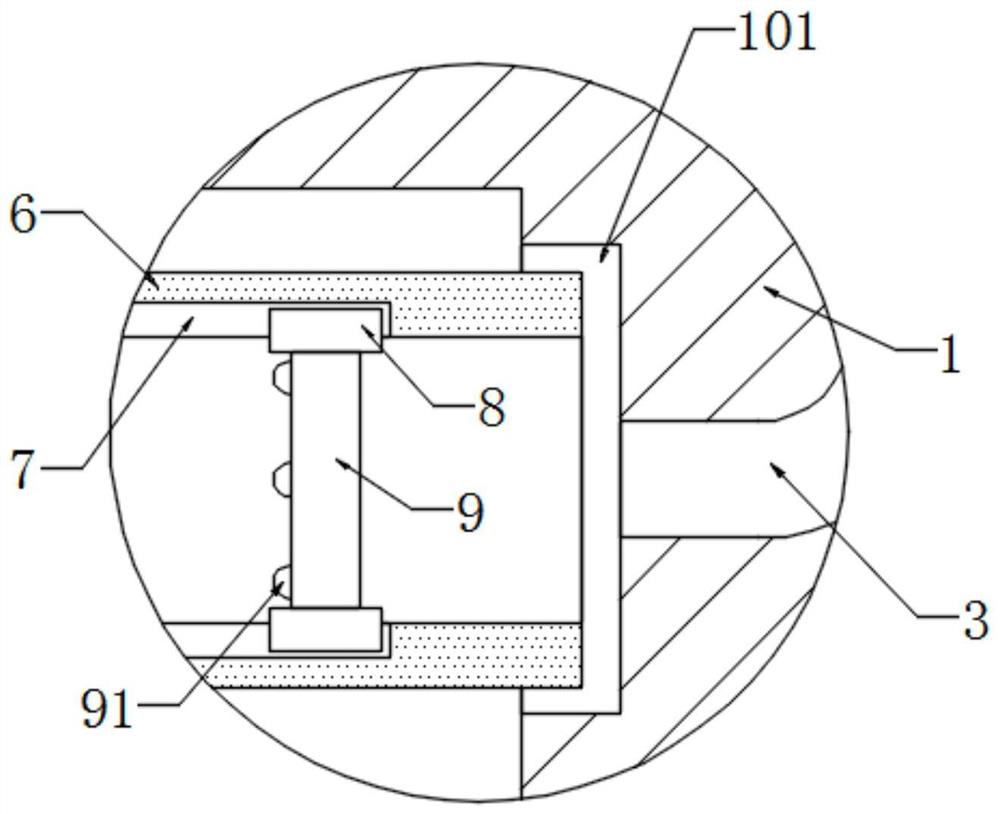

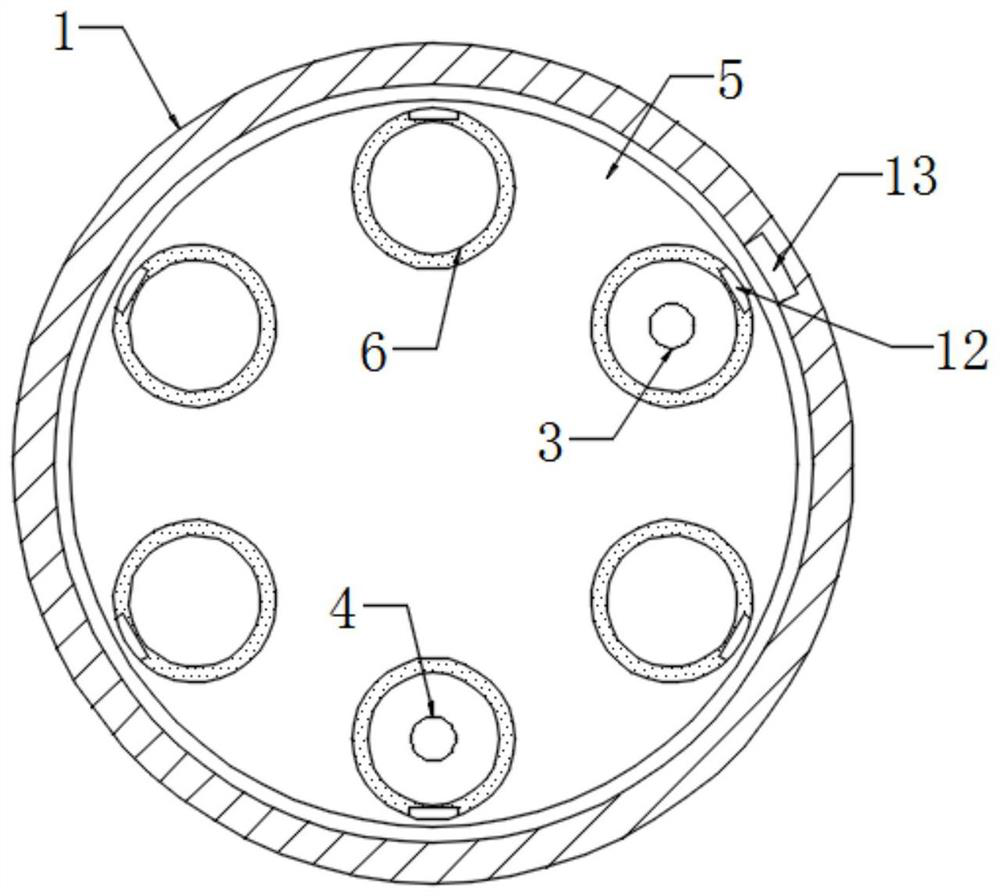

[0024] refer to Figure 1-3 , a self-cleaning dust removal system for smart household vacuum cleaners, comprising a dust collection box 1, a negative pressure tank 2 is provided on the side wall of the dust collection box 1, a negative pressure fan 201 is installed in the negative pressure tank 2, and the negative pressure tank 2 and The dust collection box 1 is connected with an air inlet pipe 3 and an air outlet pipe 4. The dust collection box 1 is rotatably connected with a rotating plate 5, and the rotating plate 5 is provided with a plurality of dust collection cylinders 6. It should be noted that the dust collection box 1 Annular grooves 101 are formed on the two opposite inner walls, and the two ends of the dust suction cylinder 6 are in close contact with the inner walls of the annular grooves 101 . There is a dust filter bag 9 slidably connected in the dust suction tube 6, and a plurality of pads 91 are fixedly connected to the side wall of the dust filter bag 9. It s...

Embodiment 2

[0031] refer to Figure 4-5 , different from Embodiment 1, the side wall of the dust outlet pipe 11 is provided with a plurality of extrusion grooves 15, and the two opposite inner walls of the extrusion groove 15 are elastically connected by a conductive spring 16, and the guide block 8 is made of a magnetic material. The vacuum tube 6 is embedded with multiple groups of helical coils 14 electrically connected to the conductive springs 16. Specifically, each group of helical coils 14 is separated by a certain distance, and when the guide block 8 moves in the guide groove 7, it will pass through each group in turn. Helical coils 14, so that each group of helical coils 14 can be energized once in turn. In addition, each conductive spring 16 is only electrically connected with one helical coil 14. Therefore, during the movement of the guide block 8, each conductive spring 16 can be sequentially energized. Stretch once. The outer wall of the dust outlet pipe 11 is made of hard p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com