A kind of flour processing equipment and processing method

A processing equipment and flour technology, applied in the field of grain processing, can solve the problems of the loss of nutrients in wheat and the inability to achieve mass production, and achieve the effects of continuous flour collection, ensuring natural purity, and avoiding high-temperature oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

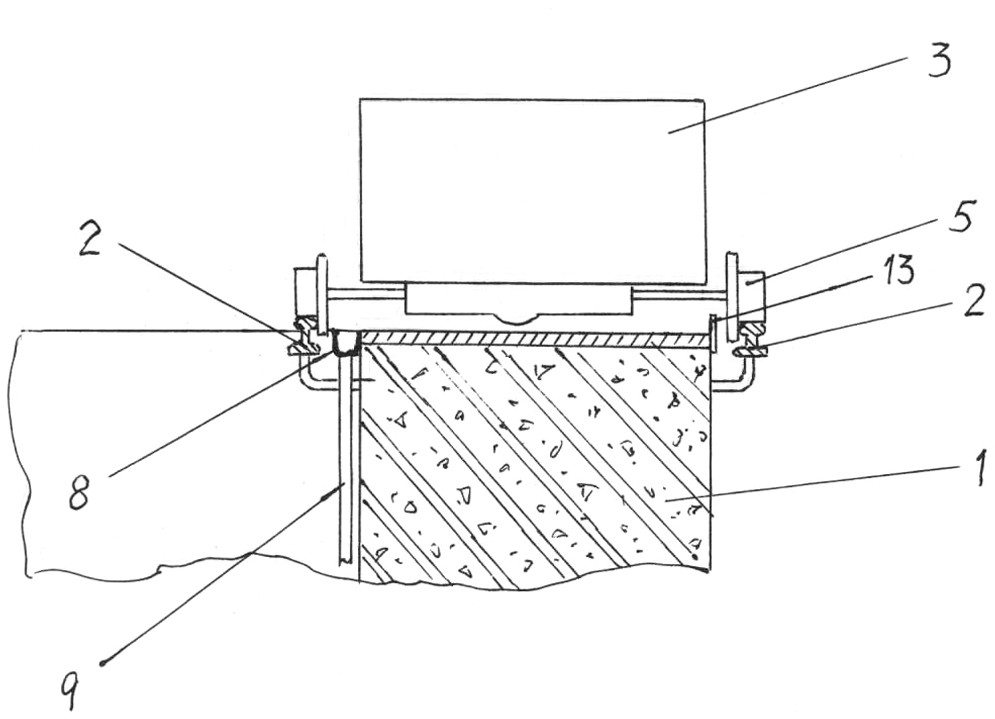

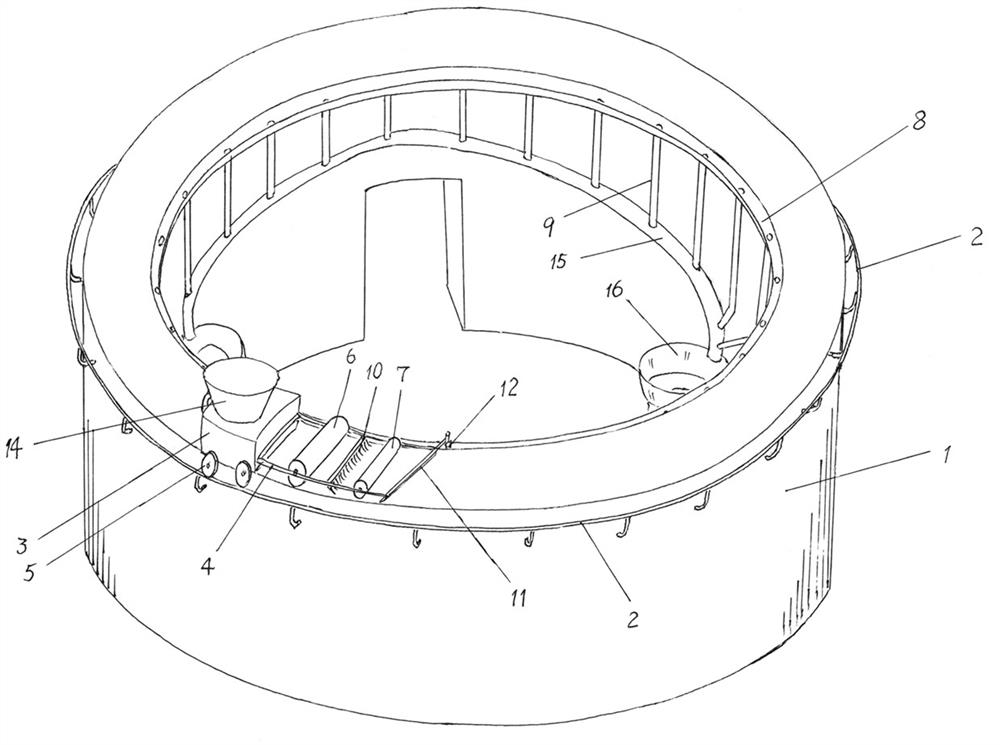

[0026] Such as figure 1 , figure 2 As shown, the flour processing equipment of the present invention includes parts such as base platform 1, track 2 and rolling car 3. The abutment 1 is a masonry structure, in the form of a cylinder, with an inner diameter of 30-100 meters. The top surface of the abutment 1 is paved with smooth granite slabs to form a circular operating table. The working platform has a width of 2-3 meters, which can be a horizontal plane, but preferably has a certain slope and is a slope with a low inside and a high outside. A baffle plate 13 ( figure 2 ) to prevent wheat grains from jumping out of the working surface during the rolling process. On the inner side wall of the abutment 1, a receiving groove 8 surrounding the inner wall of the abutment is provided, and the bottom of the receiving groove 8 is connected with a plurality of upright receiving pipes 9, and the upper end of the receiving pipe 9 communicates with the receiving groove 8. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com