Method for depositing decorative coating on iron-cobalt magnetically soft alloy and product

A soft magnetic alloy, decorative coating technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve problems such as poor adhesion, improve product quality, improve service life, expand Effects of available conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

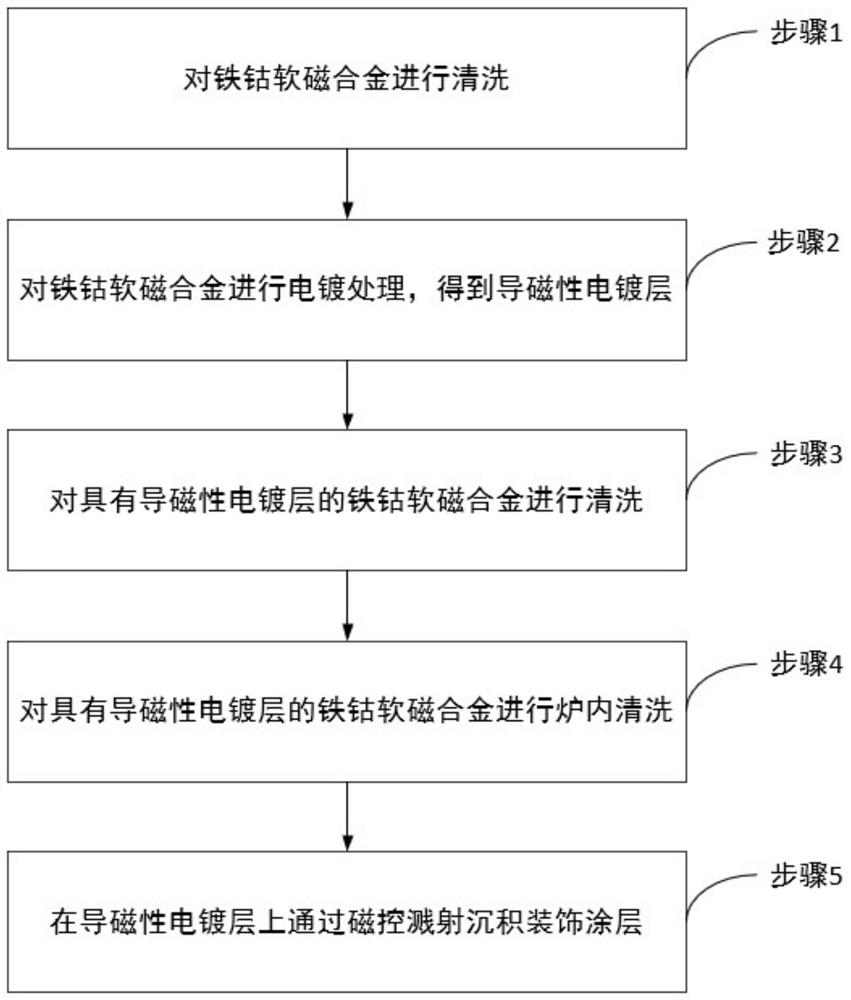

[0034] See attached figure 1 , the present embodiment provides a method for depositing a decorative coating on an iron-cobalt soft magnetic alloy, which specifically includes the following steps:

[0035] Step 1: Carry out targeted cleaning on the iron-cobalt soft magnetic alloy. The cleaning process ensures that the iron-cobalt soft magnetic alloy is clean and does not cause corrosion to the iron-cobalt soft magnetic alloy. The specific plan is as follows:

[0036] 1.1: Put the iron-cobalt soft magnetic alloy in the cleaning solution for ultrasonic cleaning. The pH value of the cleaning solution is 7-12 and the temperature is 30-80°C, which can effectively remove the oil on the surface of the iron-cobalt soft magnetic alloy. In order to further improve the degreasing ability of the cleaning agent, the pH value of the cleaning agent is preferably 8.5-10, and the temperature is 40-60°C.

[0037] 1.2: Activate the surface of the iron-cobalt soft magnetic alloy. The activator u...

Embodiment 2

[0056] This embodiment also provides an example of depositing a decorative coating on an iron-cobalt soft magnetic alloy to verify the effectiveness of the method for preparing the decorative coating of the present invention.

[0057] In step 01, the iron-cobalt soft magnetic alloy is ultrasonically cleaned, the pH value is 9, the cleaning agent concentration is 5%, the temperature is 50° C., and the time is 10 minutes.

[0058] Step 02, activating the surface, the concentration of compound weakly acidic activator is 10%, the pH value is 4, the temperature is room temperature, and the time is 3 minutes.

[0059] Step 03, plating nickel on the iron-cobalt soft magnetic alloy for 5 minutes.

[0060] Step 04, plating copper on the iron-cobalt soft magnetic alloy for 25 minutes.

[0061] Step 05, plating nickel on the iron-cobalt soft magnetic alloy for 60 minutes.

[0062] Step 06, plating chrome on the iron-cobalt soft magnetic alloy for 15 minutes.

[0063] Step 07: Ultrason...

Embodiment 3

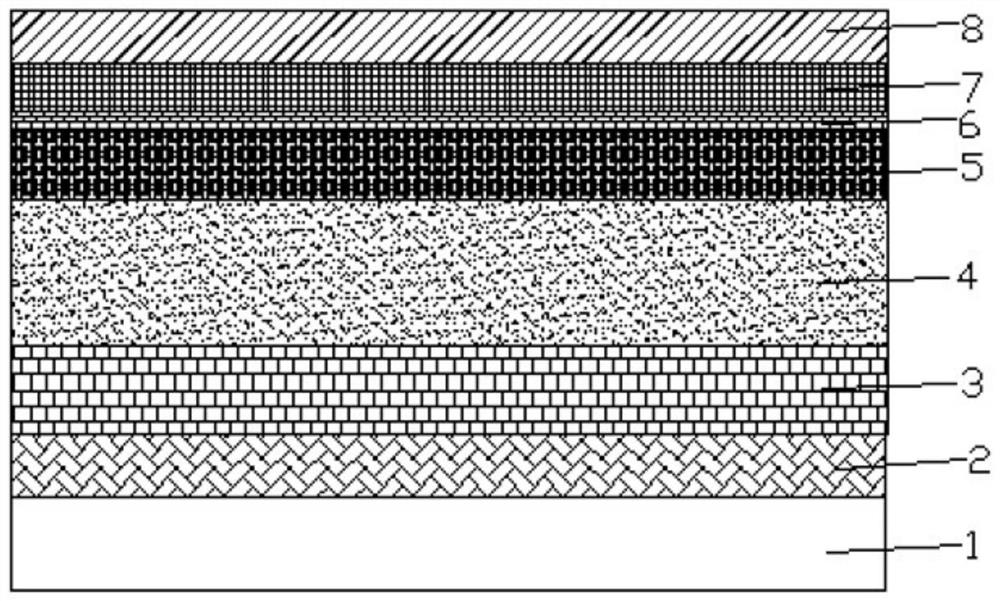

[0074] The decorative coating deposited on the iron-cobalt soft magnetic alloy is obtained by the above-mentioned embodiment, as the description attached figure 2 As shown, from the surface of the substrate 1 to the outside, it includes a magnetically permeable electroplating layer and a decorative coating, wherein the magnetically permeable electroplating layer is the first water nickel plating layer 2, the water copper plating layer 3, and the second water nickel plating layer from the inside to the outside. Layer 4, water chrome plating layer 5, and the decorative coating layer from the inside to the outside are the vacuum coating layer 6, the vacuum coating functional layer 7 and the vacuum coating color layer 8.

[0075] Wherein, the thickness of the first water-plated nickel layer 2 is 0.41 μm; the thickness of the water-plated copper layer 3 is 2.82 μm; the thickness of the second water-plated nickel layer 4 is 6.83 μm; the thickness of the water-plated chromium layer 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com