Memory card and mass production method thereof

A memory card, mass production technology, applied in the field of memory cards, can solve problems such as inflexibility and troublesome use, and achieve the effect of convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

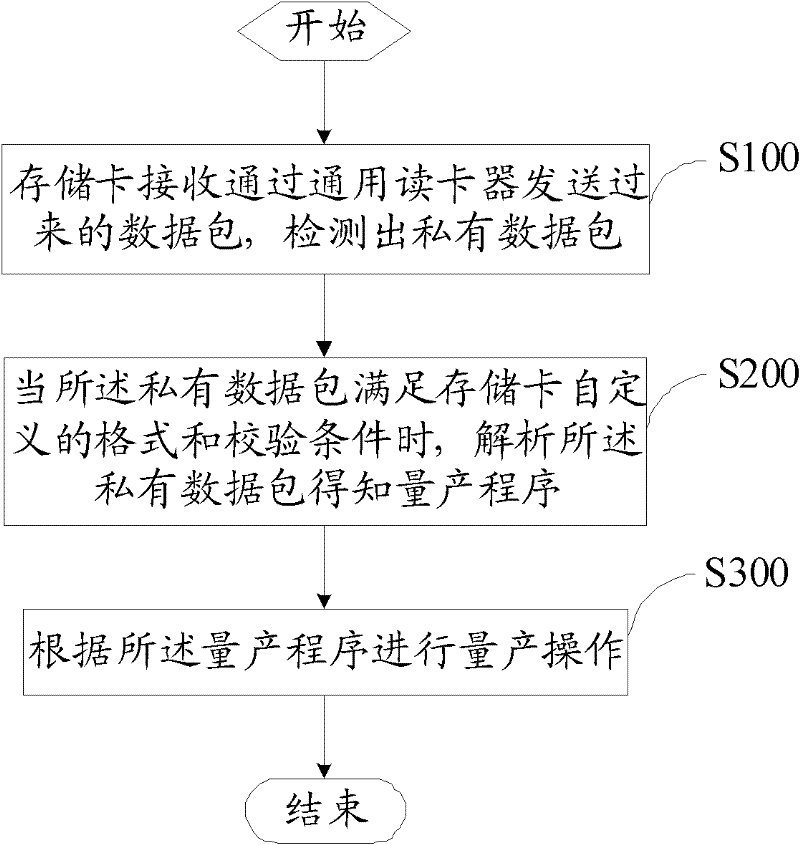

[0025] refer to figure 2 , propose an embodiment of a mass production method of a memory card of the present invention, which includes the following steps:

[0026] Step S100, the memory card receives the data packet sent by the general-purpose card reader, and detects the private data packet; the above-mentioned data packet can be sent through the PC platform or other mass production sending platforms, including ordinary data packets and private data packets, the data packet Contains mass production information and conforms to certain rules.

[0027] Step S200, when the above-mentioned private data packet satisfies the format and verification conditions defined by the memory card, analyze the above-mentioned private data packet to obtain the mass production program.

[0028] Step S300, mass production of the memor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com