Air conditioner fin mold longitudinal cutting device and cutting mode thereof

A technology of air-conditioning fins and cutting devices, which is applied in the direction of shearing devices, shearing machine accessories, manufacturing tools, etc., can solve problems such as loud noise, poor shock absorption and buffer performance, and a large amount of dust, so as to reduce pollution and improve The effect of shock absorption and cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

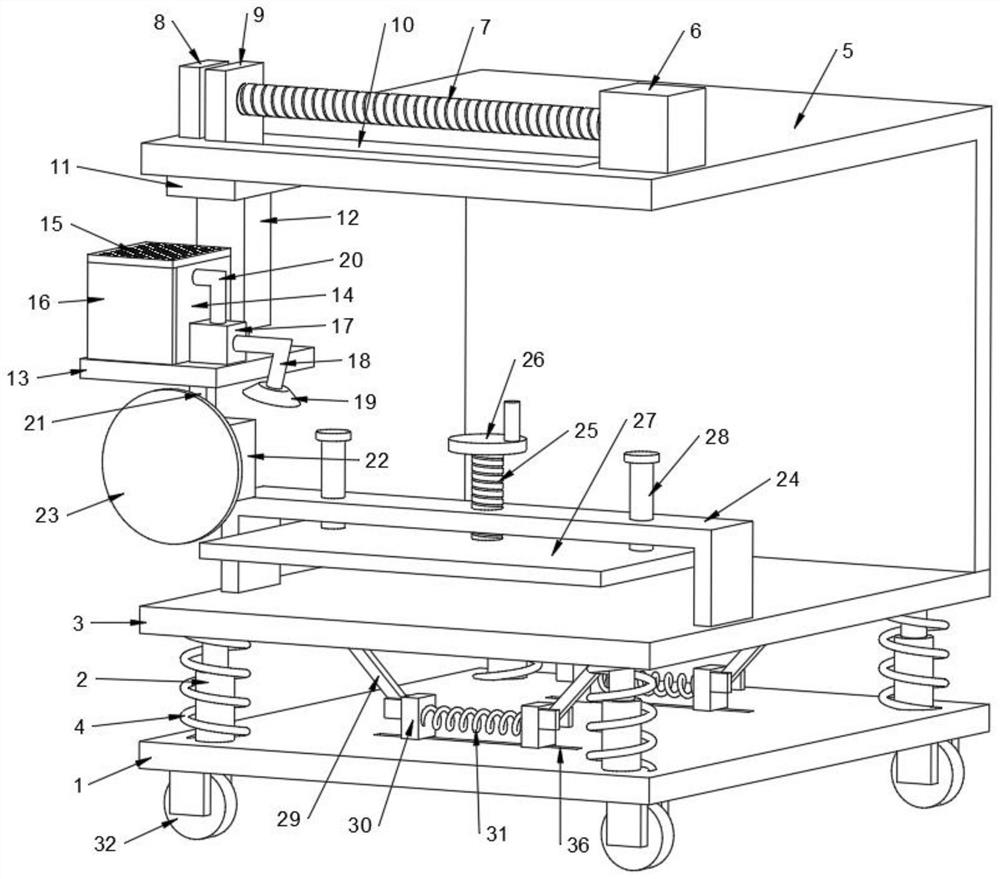

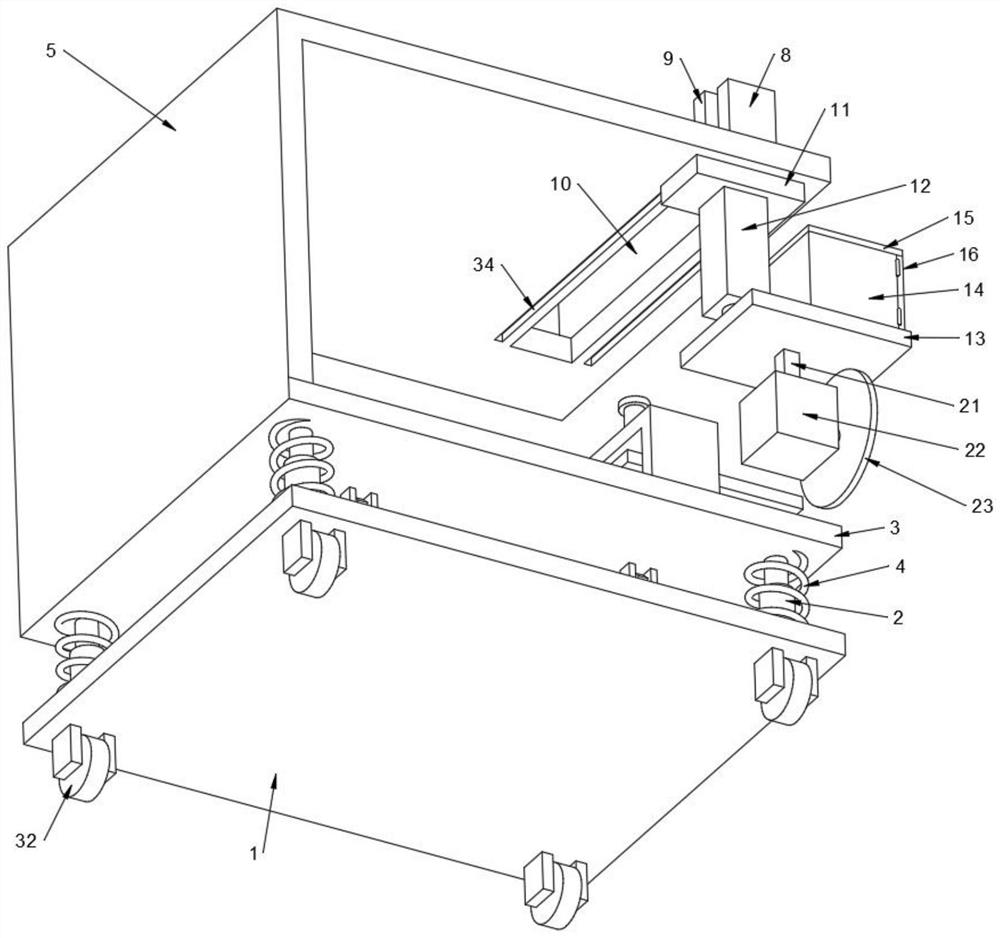

[0030] see Figure 1-6 , the present invention provides the following technical solutions: a slitting and cutting device for air-conditioning fin molds, including a base 1, telescopic sleeves 2 are fixed on the top four corners of the base 1, and support plates 3 are fixed on the tops of the four telescopic sleeves 2, The outside of the telescopic sleeve 2 is provided with a first spring 4, and the two ends of the first spring 4 are respectively fixedly connected with the top of the base 1 and the bottom of the support plate 3, and the top of the support plate 3 is fixed with an L-shaped plate 5, L A servo motor 6 is fixed on one end of the top of the plate 5, a first screw rod 7 is fixed on the output shaft of the servo motor 6, a bracket plate 8 is fixed on the top of the L-shaped plate 5, and one end of the first screw rod 7 passes through the bearing and the bracket plate The side wall of 8 is rotationally connected, and the surface of the first screw mandrel 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com