Sleeve dismounting device and method based on asynchronous multi-frequency induction heating

An induction heating device and induction heating technology, applied in the field of heat treatment, can solve the problems of material waste, inability to guarantee the penetration depth of the heating area, and inconvenient removal of the casing, so as to reduce costs, ensure rapidity and uniformity, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

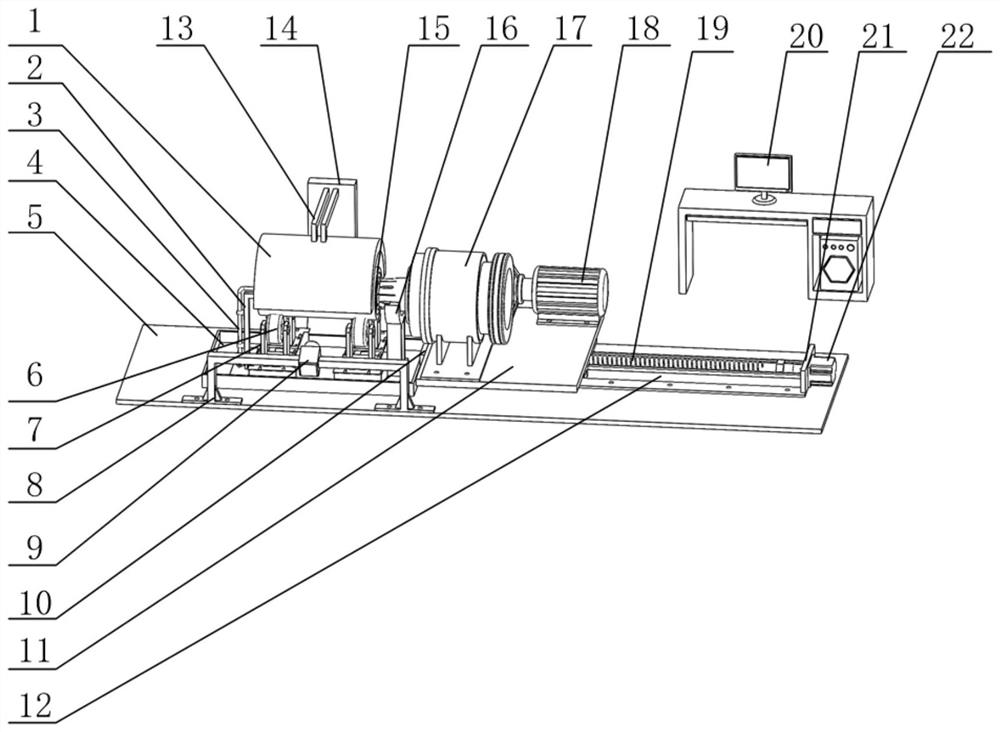

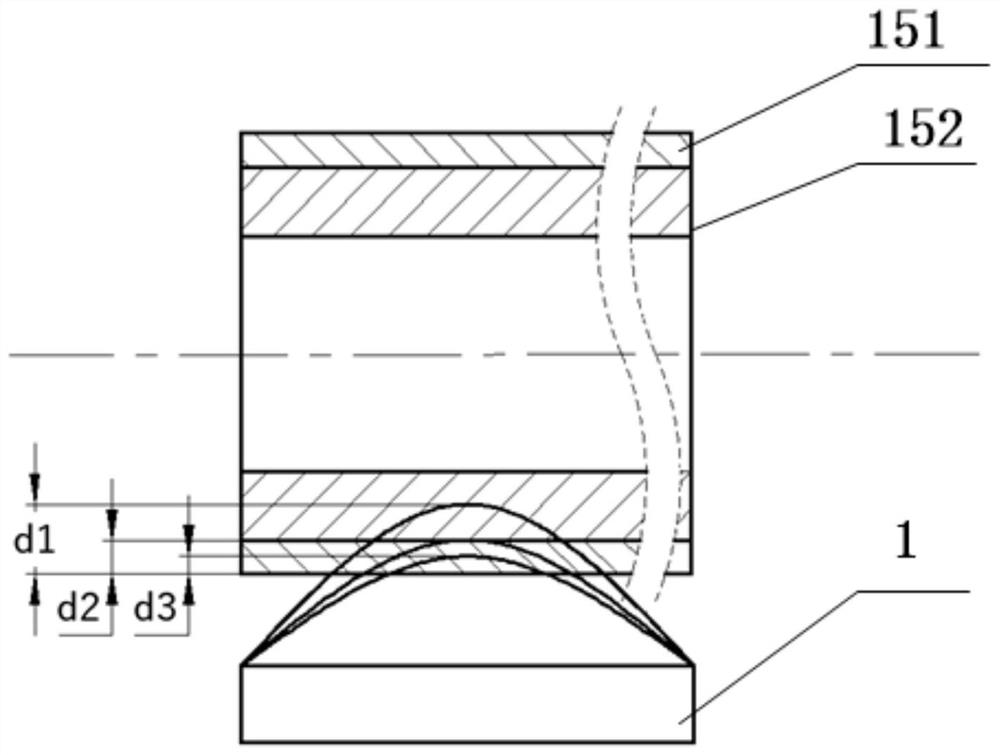

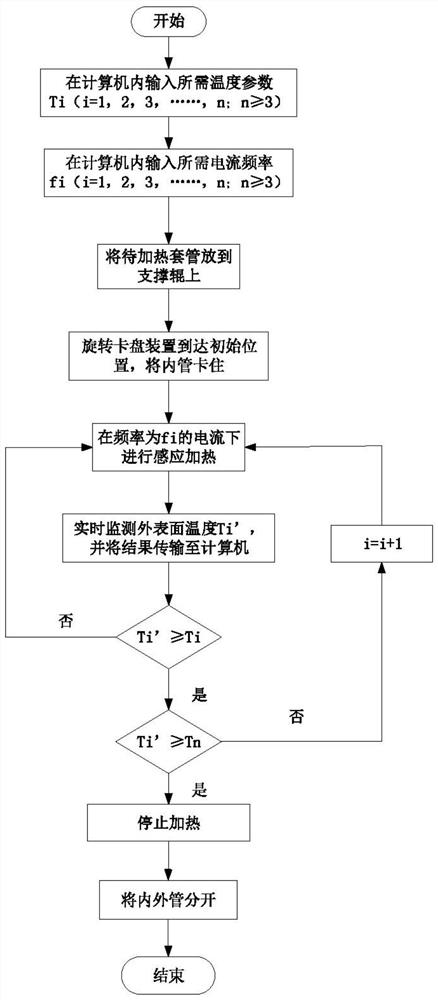

[0030] Such as figure 1As shown, a sleeve pipe removal device based on asynchronous multi-frequency induction heating includes a computer 20, a platform 5, a cooling device arranged on the platform 5, and is fixed on the platform 5 for catching the ejection from the cooling device. The cooling water tank 4, the frame 7 fixed on the platform 5, the support roller 6 arranged on the frame 7, the vertical power supply platform 14 fixed on the side of the platform 5, the multi-frequency induction heating device, Rotating chuck device, horizontal moving device, semicircular baffle plate 16 and temperature measuring device, vertical power supply platform 14 is electrically connected with computer 20; Described multi-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com