A high-temperature superconducting maglev train synchronous landing system and field cooling method

A magnetic levitation train and high-temperature superconducting technology, applied in sliding/floating railway systems, motor vehicles, electric vehicles, etc., can solve the problems of large position control error, lack of automatic control system, and difficulty in ensuring synchronous lifting field cooling, etc., to achieve improved The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

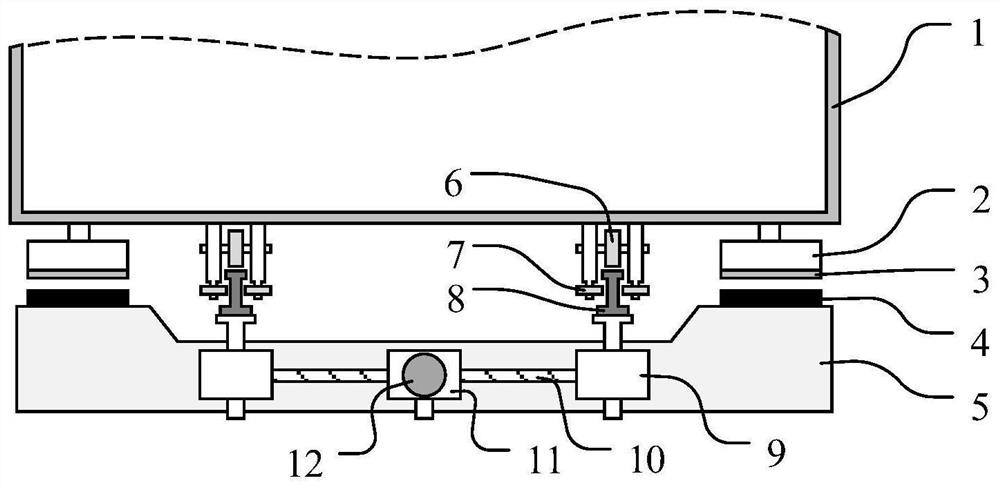

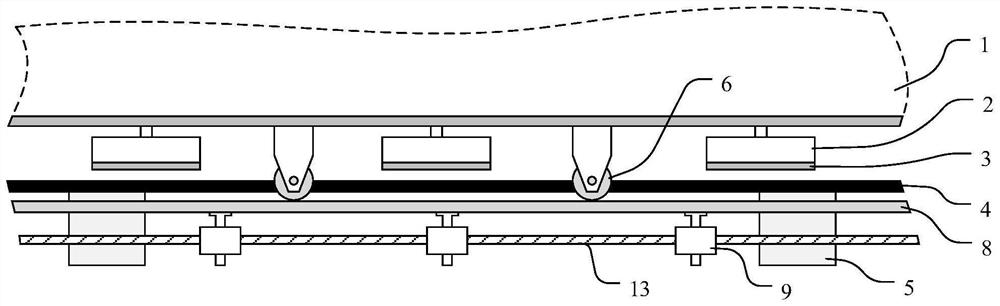

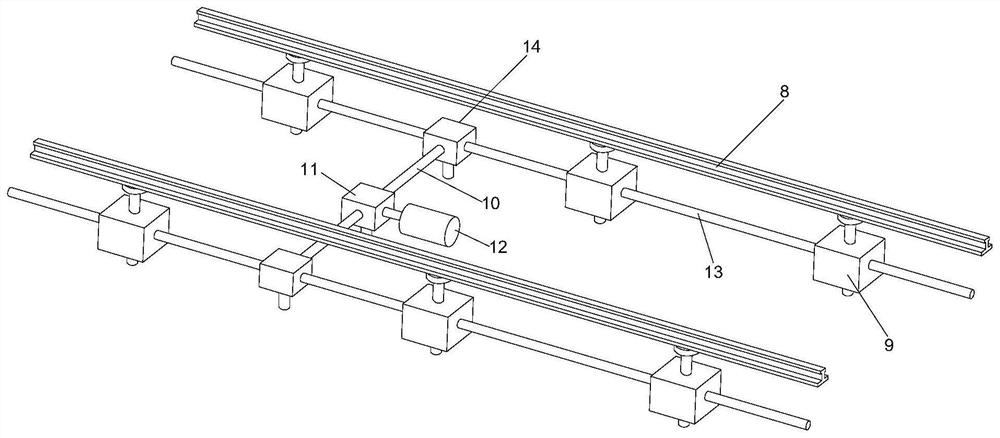

[0039] like Figure 1-3 As shown in the figure, the present invention is a high-temperature superconducting maglev train synchronous take-off and landing system. Suspended Dewars 2 are respectively provided on both sides of the bottom of the train body 1, and high-temperature superconducting materials 3 are fixed at the bottom of the suspended Dewars. There is a permanent magnet track 4 fixed on the sleeper 5 directly below the tile 2; the synchronous landing system includes a synchronous landing unit and an auxiliary support mechanism, and the synchronous landing unit includes a motor 12, a reversing system, a transmission shaft system and Multiple screw lifts 9, the motor 12 is connected with the multiple screw lifts 9 through the reversing system and the transmission shaft system, and the motor 12 rotates to drive the respective screw lifts 9 to rise and fall synchronously; the auxiliary support mechanism includes support wheels 6, The lateral guide wheel 7 and the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com