Chain assembly line

A technology for assembling lines and chains. It is used in cleaning devices, transportation and packaging, conveyor objects, etc. It can solve the problems of floating between the slider and the side wall of the plate cavity, the obstacle of slider lifting, and the large volume of dust particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

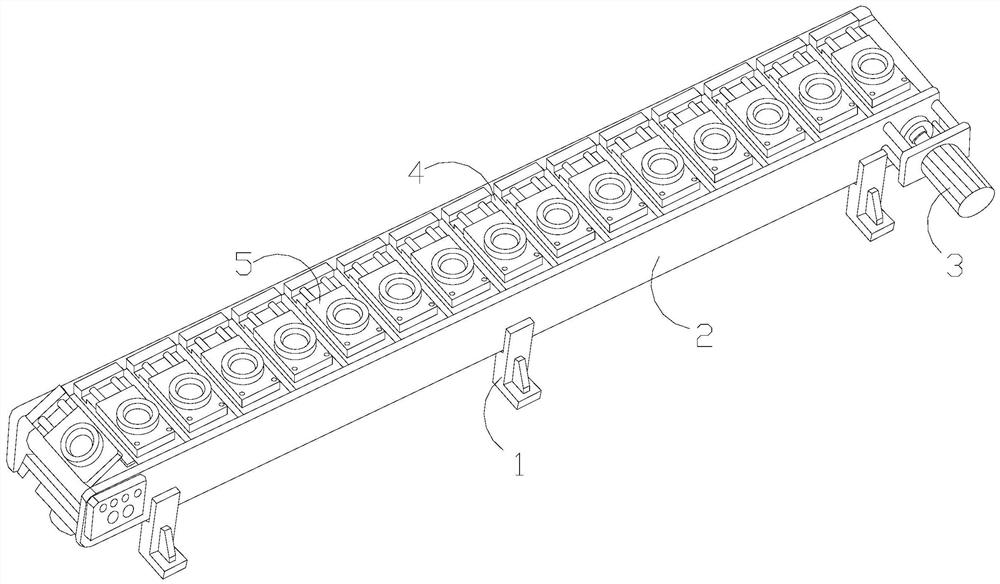

[0029] as attached figure 1 To attach Figure 6 Shown:

[0030] The invention provides a chain assembly line, the structure of which is provided with a foot base 1, a whole board 2, a driving roller 3, a chain 4, and a bearing seat 5. The foot base 1 is embedded and connected under the whole board 2, and the driving The roller 3 is installed through one side of the whole board 2, the chain 4 is movable on the top surface of the whole board 2, and the bearing seat 5 is installed on the chain 4 and movably matched.

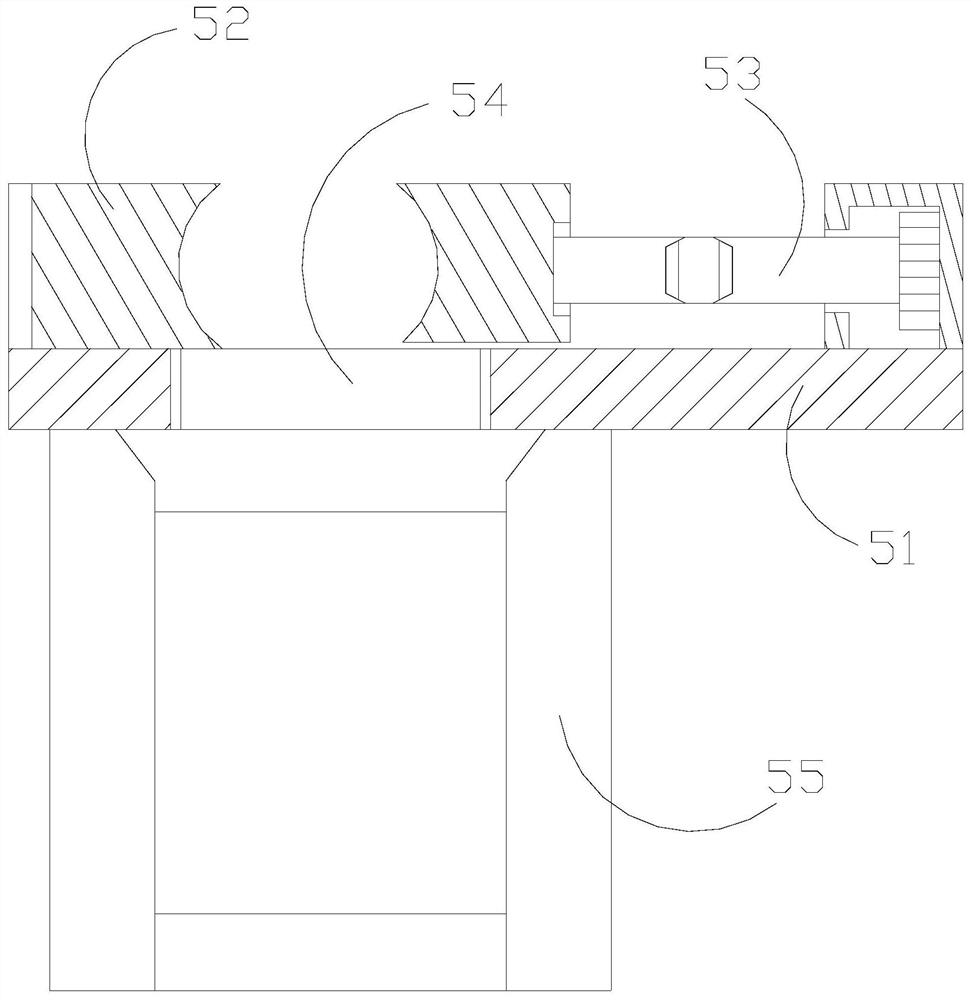

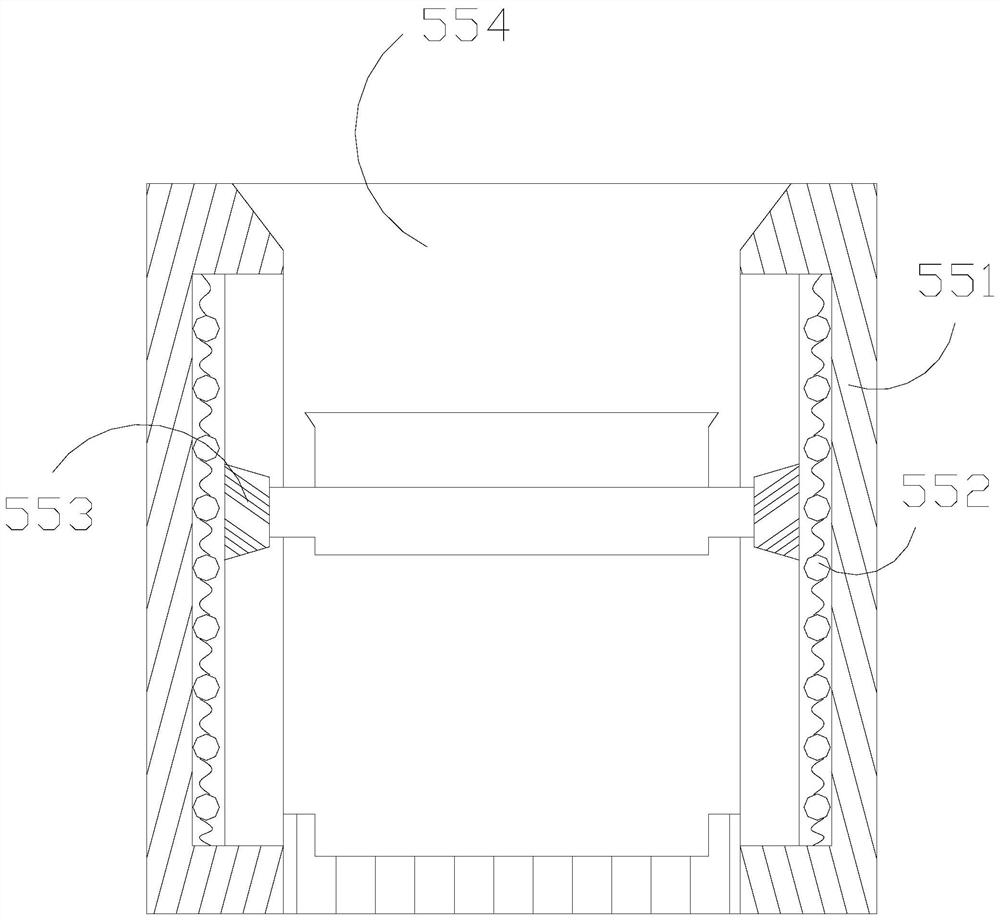

[0031] The bearing seat 5 is provided with a middle bearing plate 51, a clip seat 52, an adjusting pressure rod 53, a through-carrying cavity 54, and a lower support body 55. Cooperating with the clamping seat 52, the load-carrying chamber 54 and the middle bearing plate 51 are integrated structures and communicate with each other. The lower support body 55 is installed under the middle bearing plate 51. 54 are interconnected and coordinated in activities.

[00...

Embodiment 2

[0038] as attached Figure 7 To attach Figure 8 Shown:

[0039] Wherein, the abutting body a3 is provided with a through plate q1, an inner groove q2, a half-capsule holding block q3, and a shovel block q4. The contact block q3 is movably fitted under the shovel block q4, and the shovel block q4 is embedded in the inner groove q2 and engages in a movable manner. Two, distributed at the port positions on both sides of the through plate q1, and are in the shape of a hemisphere, made of plastic elastomer material, with excellent elastic force, the shovel block q4 snaps together under the elastic resistance of the half-capsule block q3 The port is on the side of the through plate q1, and has an inclined angle, which is convenient for removing foreign objects, and then falls out from the through plate q1 when the apex a3 is turned upside down.

[0040] Wherein, the shovel block q4 is provided with a hinge pulley w1, a solid block w2, a drop port w3, and a flow path w4. The mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com