Method and device for continuously adjusting valence state and acidity of neptunium in Purex process 1CU feed liquid

A technology of feed liquid and acidity, applied in the field of continuous adjustment of neptunium valence and acidity in 1CU feed liquid of Purex process, can solve the problems of batch operation and cumbersome steps, avoid operation, short residence time, and simple process operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

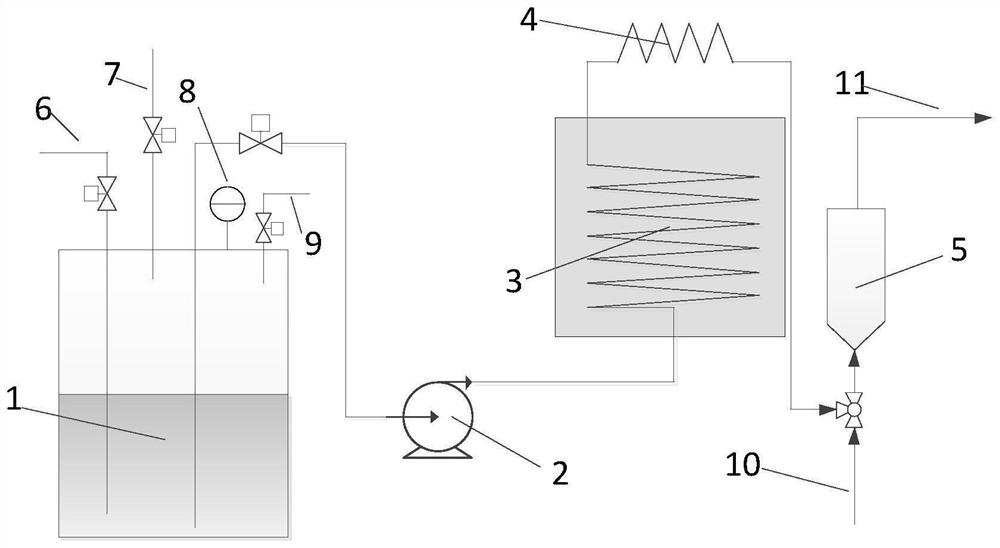

[0054] Specific steps are as follows:

[0055] (1) Use negative pressure to extract a certain volume of 1CU feed liquid in the 1CU feed liquid tank, add a certain volume of nitric acid, keep the acidity in the tank at about 0.1mol / L, and add a certain concentration of Np (IV) feed liquid, Make the Np(IV) concentration in the tank at 2mg / L;

[0056] (2) Control the temperature of the heating coil to be 60°C, and use a feed liquid pump to deliver 1CU of feed liquid to the heating coil with a certain flow rate, so that the residence time in the heating coil is 3 hours;

[0057] (3) After that, 1CU of feed liquid is cooled to 40°C through the cooling coil;

[0058] (4) Finally, according to the 1CU feed liquid flow rate and acidity, and the acidity of the final discharge—2DF, calculate the flow rate of the concentrated nitric acid that needs to be input in the static mixer, so that the treated 1CU feed liquid and concentrated nitric acid are statically mixed It is mixed in the r...

experiment example 2

[0061] Specific steps are as follows:

[0062] (1) Use negative pressure to extract a certain volume of 1CU feed liquid in the 1CU feed liquid tank, add a certain volume of nitric acid, keep the acidity in the tank at about 0.5mol / L, and add a certain concentration of Np (IV) feed liquid, Make the Np(IV) concentration in the tank at 2mg / L;

[0063] (2) Control the temperature of the heating coil to be 90°C, and use a feed liquid pump to deliver 1CU of feed liquid to the heating coil with a certain flow rate, so that the residence time in the heating coil is 0.5 hour;

[0064] (3) After that, 1CU of feed liquid is cooled to 40°C through the cooling coil;

[0065] (4) Finally, according to the 1CU feed liquid flow rate and acidity, and the acidity of the final discharge—2DF, calculate the flow rate of the concentrated nitric acid that needs to be input in the static mixer, so that the treated 1CU feed liquid and concentrated nitric acid are statically mixed It is mixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com