A kind of anodized die-casting aluminum alloy and preparation method thereof

A technology of casting aluminum alloy and anodizing, which is applied in the field of aluminum alloy and its casting, can solve the problems of aluminum alloy decorative products having no competitive advantage, discontinuous oxide film, reducing mechanical properties of castings, etc., so as to improve the effect of solid solution strengthening. , The effect of improving anodizing performance and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

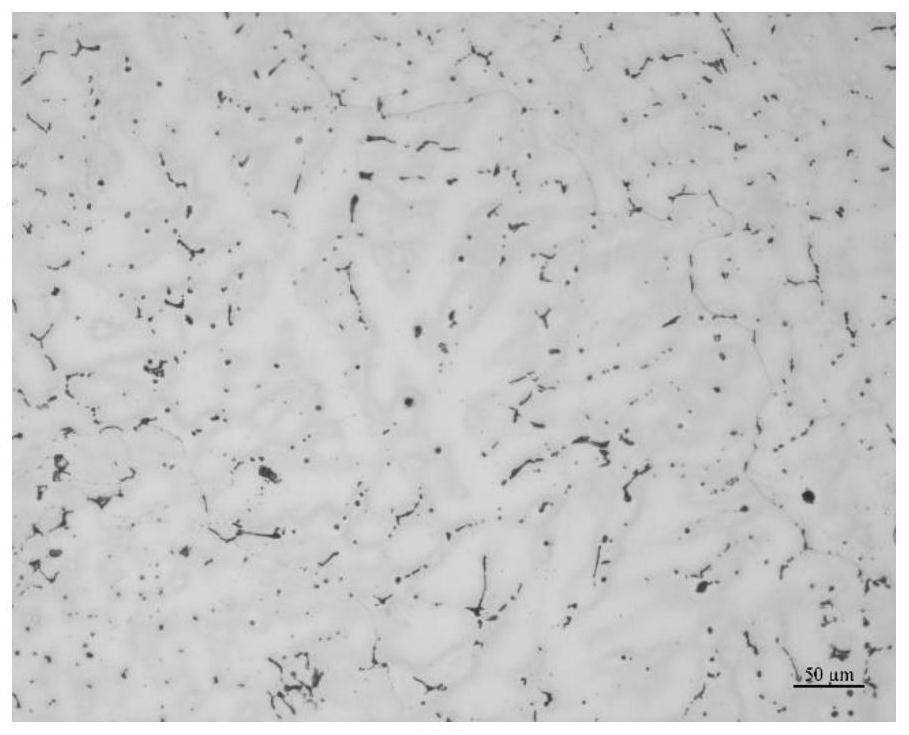

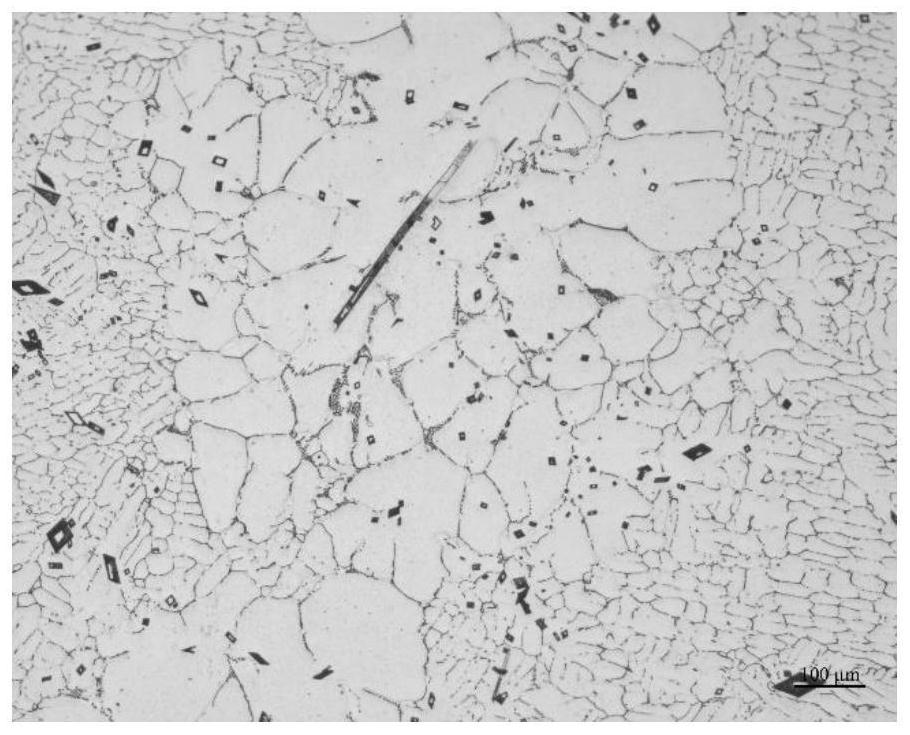

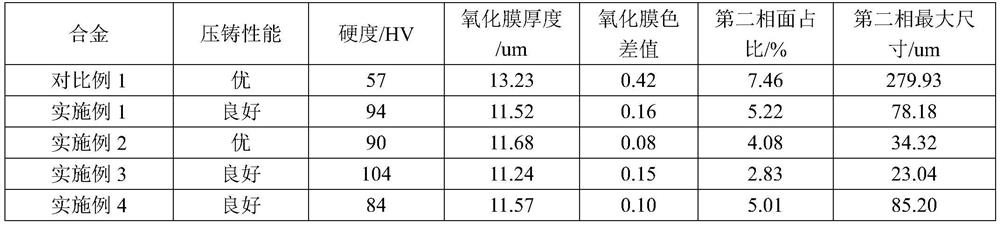

Image

Examples

preparation example Construction

[0019] A method for preparing an anodic oxidation die-casting aluminum alloy, comprising the following steps:

[0020] (1) Put the industrial pure Al ingot, industrial pure Zn ingot, Al-Mn master alloy, and Fe agent in the melting furnace and heat it to 780°C-800°C. After the raw materials in the melting furnace are melted, the melting furnace is cooled to 760°C -770°C, then press the pure Mg and Al-Zr master alloy into the bottom of the furnace body of the melting furnace until the pure Mg and Al-Zr master alloy are completely melted to obtain the melted material.

[0021] (2) Add refining agent and refiner to the smelting furnace, stir and degas for 15min-20min, stand still for 15min-20min, and remove the slag to obtain the sample after removing the slag; the refining agent is block or granular sodium-free refining agent , the refiner is Al-Ti-B. The addition of refining agent is the quality of industrial pure Al ingot, the quality of industrial pure Zn ingot, the quality o...

Embodiment 1

[0026] Put the raw materials of industrial pure Al ingot, industrial pure Zn ingot, Al-Mn master alloy, and Fe agent in the melting furnace and heat to 800°C. After the raw materials in the melting furnace are melted, the melting furnace is cooled to 760°C, and then the pure Mg and The Al-Zr master alloy is pressed into the bottom of the furnace body of the smelting furnace until the pure Mg and the Al-Zr master alloy are completely melted to obtain the melted material.

[0027] After adding sodium-free refining agent and Al-Ti-B refining agent into the smelting furnace, stir for degassing for 15 minutes, stand still for 15 minutes after degassing, and remove slag to obtain a sample after deslagging. The addition amount of sodium-free refining agent is 2‰ of raw material quality, and the addition amount of Al-Ti-B refining agent is 3‰ of raw material quality.

[0028] When the temperature of the sample after slag removal reaches 740°C, casting is carried out to obtain anodized...

Embodiment 2

[0030] Put industrial pure Al ingots, industrial pure Zn ingots, Al-Mn master alloys, and Fe agents in a melting furnace and heat them up to 800°C. After the raw materials in the melting furnace are melted, cool down the melting furnace to 760°C, and then pure Mg and Al The -Zr master alloy is pressed into the bottom of the furnace body of the smelting furnace until the pure Mg and Al-Zr master alloy are completely melted to obtain the melted material.

[0031] After adding sodium-free refining agent and Al-Ti-B refining agent into the smelting furnace, stir for degassing for 15 minutes, stand still for 15 minutes after degassing, and remove slag to obtain a sample after deslagging. The addition amount of sodium-free refining agent is 3‰ of raw material quality, and the addition amount of Al-Ti-B refining agent is 3‰ of raw material quality.

[0032] When the temperature of the sample after slag removal reaches 740°C, casting is carried out to obtain anodized die-casting alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com