Anodizable cast aluminum alloy and preparation method thereof

A casting aluminum alloy and anodic oxidation technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems of unsatisfactory comprehensive performance of aluminum alloy casting fluidity and mechanical properties, so as to improve anodic oxidation performance, increase thickness, and improve casting fluidity and mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

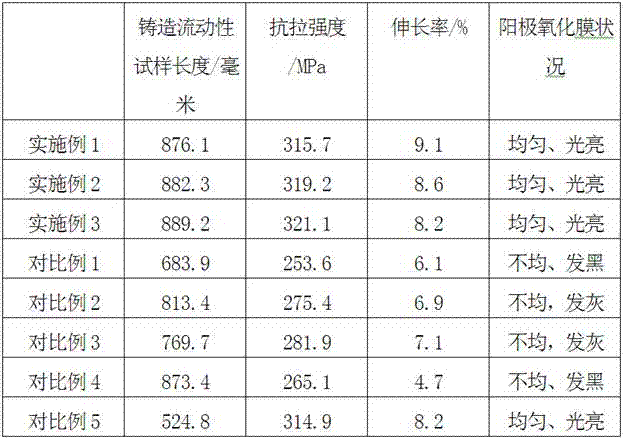

[0028] The anodizable castable aluminum alloy of the present invention contains 3.5% Mg, 2.5% Si, 0.05% Ti, 0.05% Eu, 0.1% Re, and the rest is Al and unavoidable impurities, wherein the composition and mass percentage of Re For: Tb 28%, Dy 22%, Ho 17%, Tm 13%, Yb 12%, Lu 8%. Its preparation method is as follows:

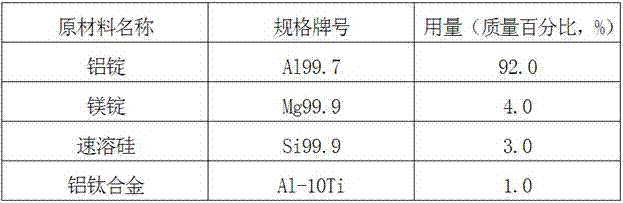

[0029] Step 1: Select Al-10Ti alloy, Al-10Eu alloy, aluminum ingot with a purity of 99.7%, magnesium ingot with 99.9%, instant silicon with 99.9% and mixed heavy rare earth Re with 99.9% as raw materials. The ingredients list is as follows:

[0030]

[0031] Step 2: Heat and melt the aluminum ingot in a crucible resistance furnace and raise the temperature to 730°C, add magnesium ingot and instant silicon, stir and melt to form aluminum alloy liquid;

[0032] Step 3: After refining and deslagging the aluminum alloy liquid with hexachloroethane, add Al-10Ti alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the composition of the aluminum alloy l...

Embodiment 2

[0037] The anodizable castable aluminum alloy of the present invention contains Mg 4.0%, Si 3.0%, Ti 0.1%, Eu 0.1%, Re 0.2%, and the rest is Al and unavoidable impurities, wherein the composition and mass percentage of Re are : Tb 28%, Dy 22%, Ho 17%, Tm 13%, Yb 12%, Lu 8%. Its preparation method is as follows:

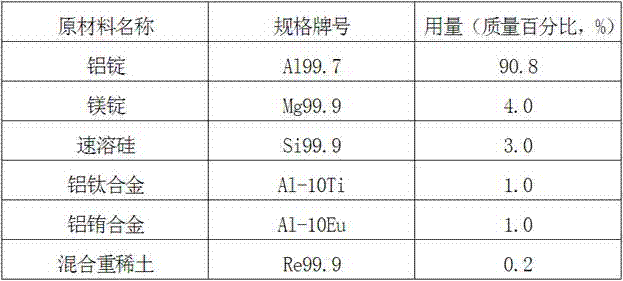

[0038] Step 1: Select Al-10Ti alloy, Al-10Eu alloy, aluminum ingot with a purity of 99.7%, magnesium ingot with 99.9%, instant silicon with 99.9% and mixed heavy rare earth Re with 99.9% as raw materials. The ingredients list is as follows:

[0039]

[0040] Step 2: Heat and melt the aluminum ingot in a crucible resistance furnace and raise the temperature to 740°C, add magnesium ingot and instant silicon, stir and melt to form aluminum alloy liquid;

[0041] Step 3: After refining and deslagging the aluminum alloy liquid with hexachloroethane, add Al-10Ti alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the composition of the aluminum alloy li...

Embodiment 3

[0046] The anodizable castable aluminum alloy of the present invention contains 4.5% of Mg, 3.5% of Si, 0.15% of Ti, 0.15% of Eu, 0.3% of Re, and the rest is Al and unavoidable impurities, wherein the composition and mass percentage of Re For: Tb 28%, Dy 22%, Ho 17%, Tm 13%, Yb 12%, Lu 8%. Its preparation method is as follows:

[0047] Step 1: Select Al-10Ti alloy, Al-10Eu alloy, aluminum ingot with a purity of 99.7%, magnesium ingot with 99.9%, instant silicon with 99.9% and mixed heavy rare earth Re with 99.9% as raw materials. The ingredients list is as follows:

[0048]

[0049] Step 2: Heat and melt the aluminum ingot in a crucible resistance furnace and raise the temperature to 750°C, add magnesium ingot and instant silicon, stir and melt to form aluminum alloy liquid;

[0050] Step 3: After refining and deslagging the aluminum alloy liquid with hexachloroethane, add Al-10Ti alloy, Al-10Eu alloy and mixed heavy rare earth Re, and stir to make the composition of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com