Patents

Literature

48results about How to "Guaranteed oxidation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of magnetic graphene oxide and application thereof

ActiveCN104923161AAvoid it happening againOptimizing dosageOther chemical processesAlkali metal oxides/hydroxidesWastewaterCoprecipitation

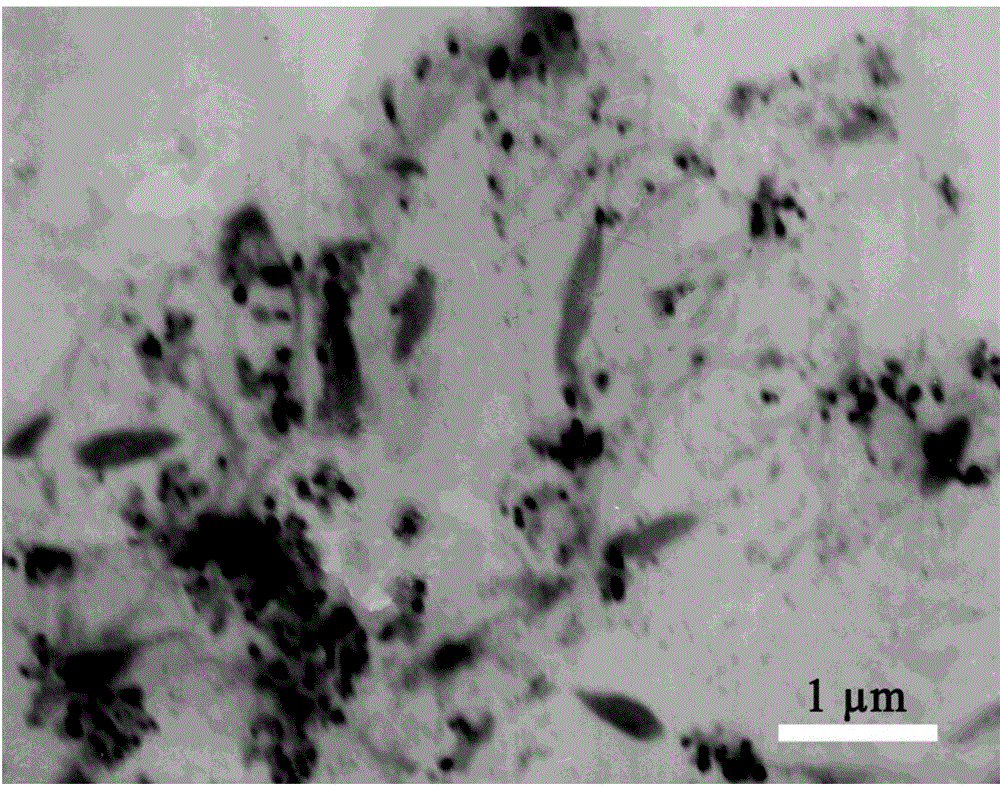

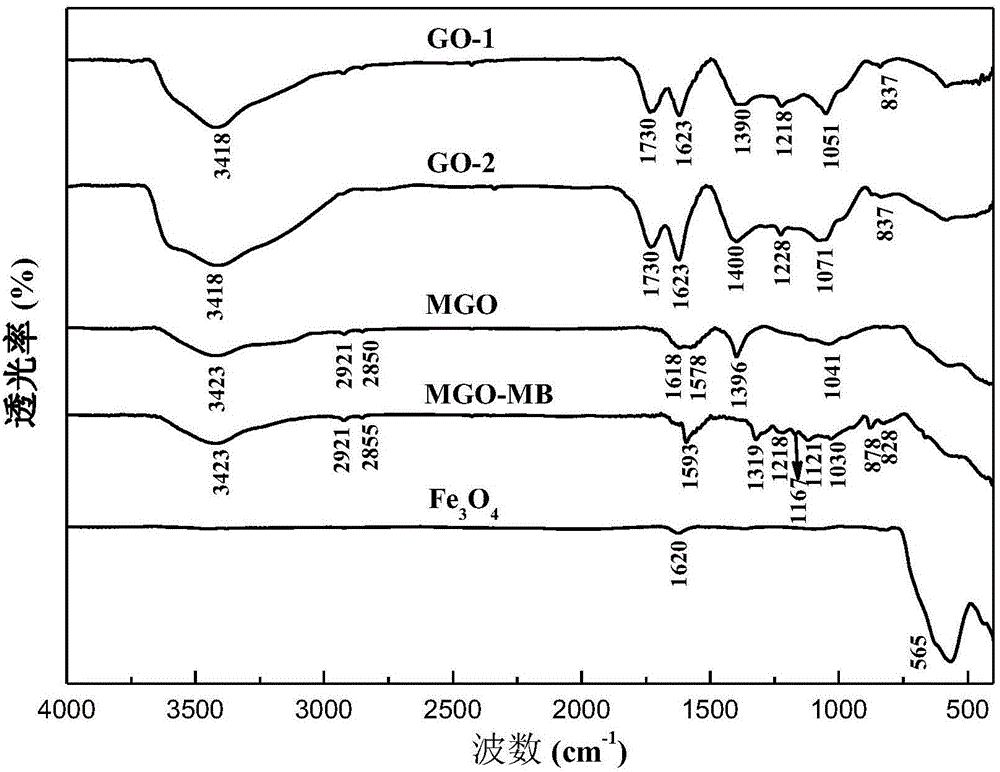

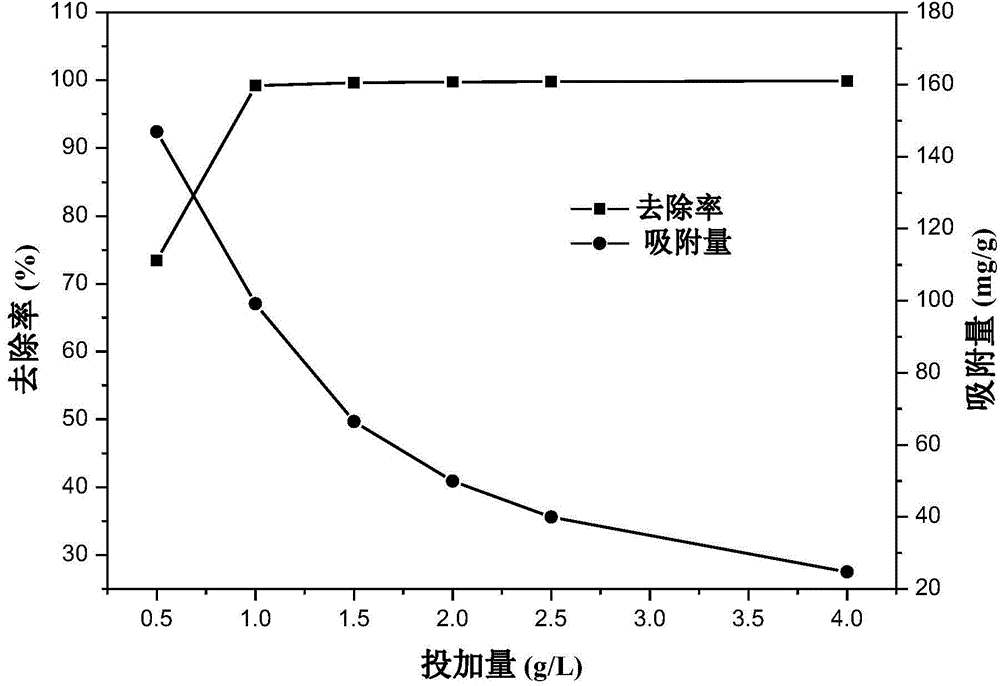

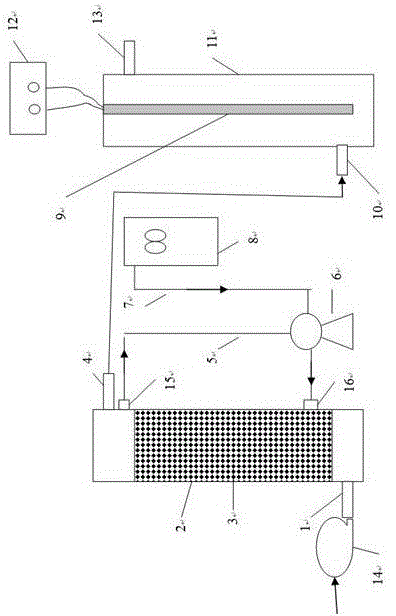

The invention discloses a preparation method of magnetic graphene oxide and application thereof. The preparation method comprises the following steps: 1 preparing mother liquor; 2 measuring the content of graphene oxide in the mother liquor; 3 obtaining an adsorbing material, namely the magnetic graphene oxide, by utilizing the mother liquor, FeCl[3].6H[2]O, FeSO[4].7H[2]O and stronger ammonia water. The magnetic graphene oxide prepared through the method is used for processing waste water containing methylene blue. According to the method, the graphene oxide is compounded through the improved Hummers method, ferroferric oxide nano-particles are loaded on a graphene oxide layer according to a certain proportion through a coprecipitation method, the obtained magnetic adsorbing material is used for the absorption treatment of a methylene blue solution, the synthetic process is simplified, the oxidation effect is guaranteed, and meanwhile the energy consumption is reduced, the time is saved, and the preparation cost is reduced; the magnetic adsorbing material which is applicable to different magnetic field environments and methylene blue waste water of different types of concentration is obtained, and the material can be recycled repeatedly.

Owner:SHANDONG UNIV

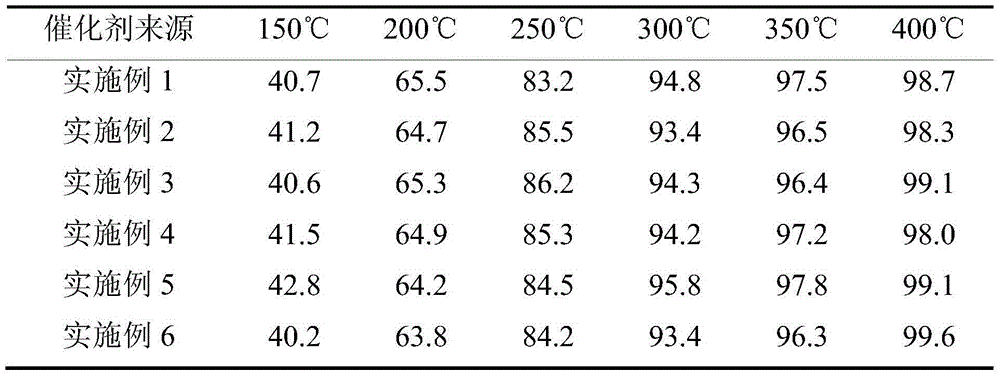

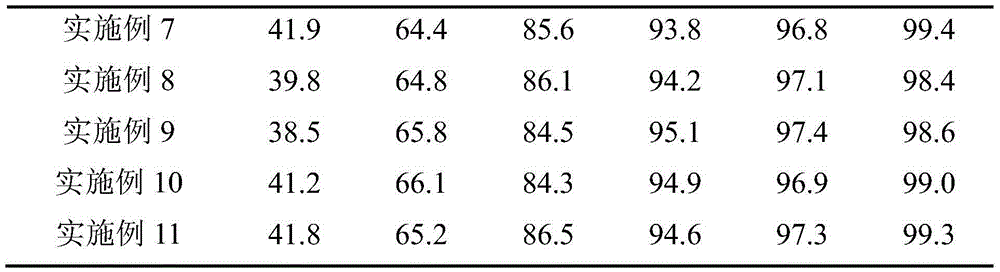

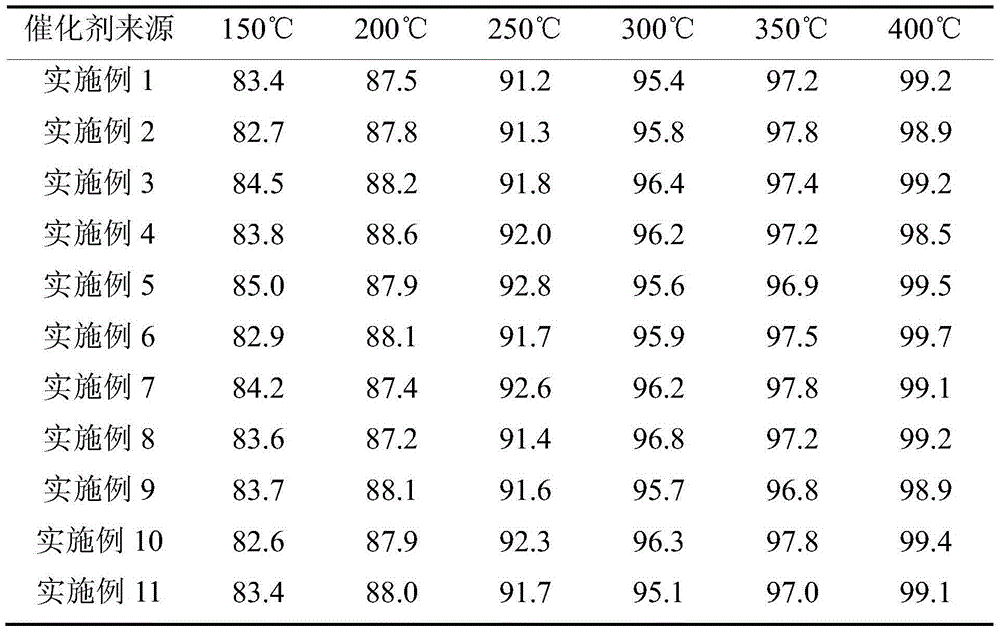

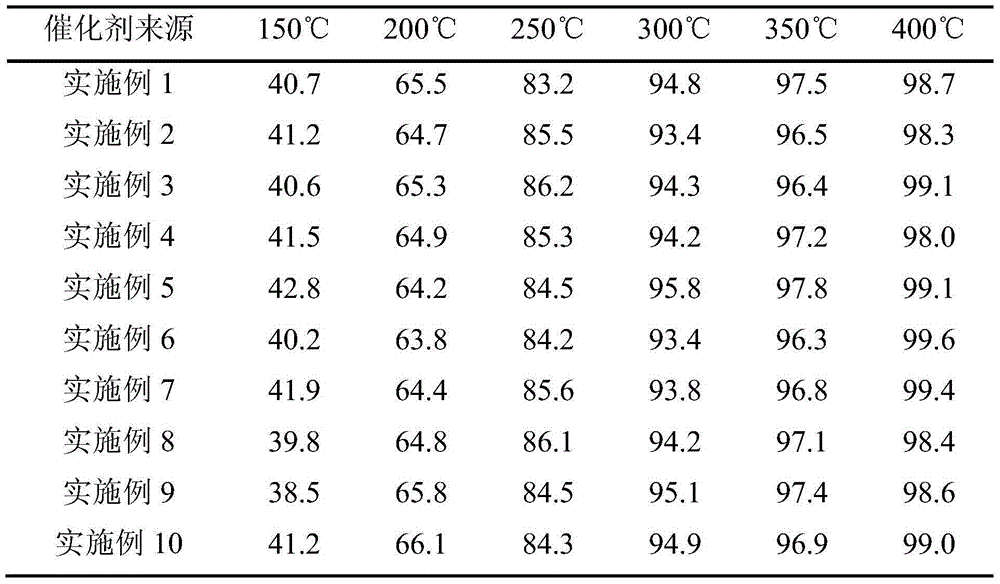

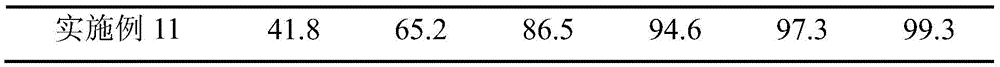

Application of metal oxide modified CePO4 catalyst to collaborative denitration and demercuration

InactiveCN104888602AEasy to operateRaw materials are readily availablePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses application of a metal oxide modified CePO4 catalyst to collaborative denitration and demercuration. The application includes introducing medium-high temperature flue gas containing elemental mercury and nitrogen oxide into a catalyst loaded catalytic apparatus. Specifically, the main component of the catalyst is cerium phosphate, and the modification component is at least one of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum and tin metal oxides. The temperature of the medium-high temperature flue gas is 250-420DEG C. According to the application of the metal oxide modified CePO4 catalyst to collaborative denitration and demercuration, the oxidation efficiency to null valence mercury in high temperature flue gas is high, the NO is the flue gas can promote and enhance the catalytic efficiency of the catalyst, and the practicability is strong. In addition, the catalyst has good medium-high temperature SCR activity and anti-sulfur and waterproof performance.

Owner:ZHEJIANG UNIV

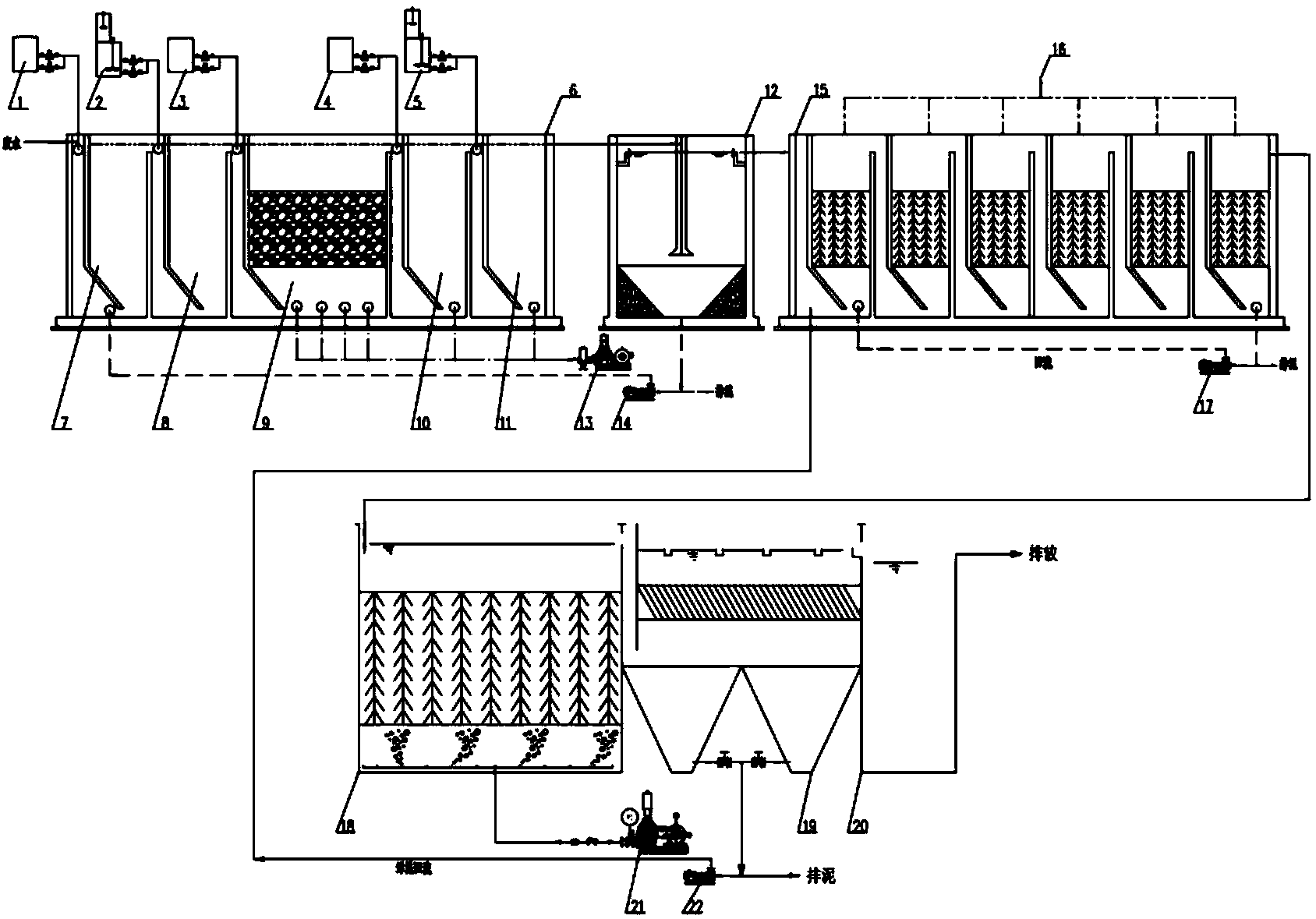

Advanced oxidation-biological treatment device for non-biodegradable waste water

ActiveCN103755097AImprove the efficiency of drug useReduce energy consumptionMultistage water/sewage treatmentAnaerobic digestionReclaimed water

The invention relates to an advanced oxidation-biological treatment device for non-biodegradable waste water. The device comprises a baffle plate Fenton reactor (6), a precipitating pond (12), a baffle plate anaerobic pond (15) and a contact oxidization pond (18). Waste water to be treated flows through each reaction pond of the baffle plate Fenton reactor in sequence, reacts and enters the precipitating pond for precipitating, supernate in the precipitating pond enters each compartment of the baffle plate anaerobic pond in sequence for undergoing anaerobic digestion, water undergoing anaerobic treatment in the baffle plate anaerobic pond enters the contact oxidation pond for undergoing aerobic treatment, treated effluent enters an oblique-tube precipitating pond, and sludge undergoing secondary precipitation in the oblique-tube precipitating pond returns to the foremost end of the baffle plate anaerobic pond through a sludge reflux pump to realize reduction of the residual sludge, and treated water is stored in the reclaimed water pond. Compared with the prior art, the advanced oxidation-biological treatment device has the advantages of high agent use efficiency, low energy consumption, simple structure and remarkable increase of the sludge digesting efficiency and the gas yield.

Owner:SHANGHAI JIAO TONG UNIV

Method for purifying yellow phosphorus by using methods of activated carbon adsorption together with dilute nitric acid rinsing

ActiveCN102107859AAdequate adsorption capacityImprove adsorption capacityPhosphorus compoundsHigh concentrationActivated carbon

The invention discloses a method for purifying yellow phosphorus by adopting methods of activated carbon adsorption together with dilute nitric acid rinsing. Firstly, activated carbon and molten industrial yellow phosphorus are mixed and stirred in a refining kettle, and after the adsorption is completed, the activated carbon is separated from the yellow phosphorus by a filter machine; then the processed yellow phosphorus is circularly rinsed with dilute nitric acid in an acid pickling tower; residual organic matters, arsenic and low-price metal ions in the yellow phosphorus, which are not adsorbed by the activated carbon, are oxidized by utilizing the oxidizability of the dilute nitric acid; and afterwards, the yellow phosphorus is circularly rinsed in a water washing tower by using deionized water, thereby completing yellow phosphorus purification. The invention adopts a process with treatment methods of activated carbon adsorption, dilute nitric acid rinsing and deionized water rinsing, and integrates the advantages of various methods; and the content of arsenic in the acquired yellow phosphorus is reduced to below 20 ppm, so that high-purity yellow phosphorus satisfying the requirement for producing electronic grade phosphoric acid can be acquired, and the hidden danger of explosion caused by using high concentration nitric acid is avoided.

Owner:湖北兴福电子材料股份有限公司

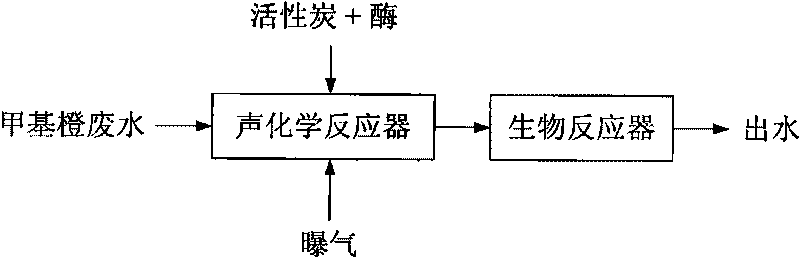

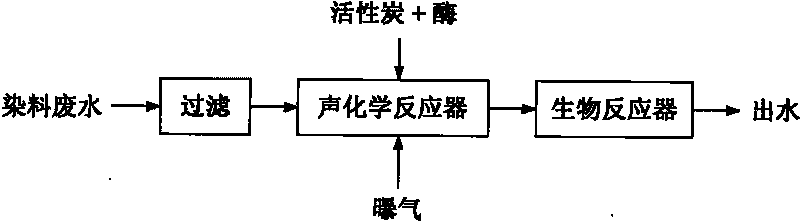

Method for treating dye wastewater with high concentration by using technology combining ultrasound wave with enzyme

InactiveCN101734803APromote degradationEfficient and stable degradation abilityWater/sewage treatment with mechanical oscillationsWater/sewage treatment by sorptionHigh concentrationPretreatment method

The invention relates to a method for treating dye wastewater with high concentration by using a technology combining ultrasound wave with enzyme, comprising the following steps of: feeding the treated active carbon in a sonochemical reactor; attaching enzyme to the surface of the active carbon and holes; filtering and removing large-particle suspended substances in the dye wastewater; introducing the large-particle suspended substances into the sonochemical reactor; under the aeration condition, radiating the fluidized state active carbon to which the enzyme is attached by using ultrasound wave with the frequency 40kHz and the power of 40W; generating a hydroxyl free radical with extremely-strong oxidation capacity and adsorption and decolorization reaction of the active carbon by using the coupling action of ultrasound-enzyme technology, thereby improving the biochemical property of the wastewater; and enabling the treated dye wastewater flowing out of the sonochemical reactor and then entering a bioreactor for further degrading. The invention has remarkable decolorization effect of the wastewater and greatly improves the biochemical property when being used as a pretreatment method of the dye wastewater with high concentration.

Owner:HEFEI UNIV OF TECH

Double-effect catalytic ozonation wastewater treatment device and method

InactiveCN106145309ADeepen processing depthDeep processingWater/sewage treatment by irradiationWater treatment compoundsOzone generatorUltraviolet

The invention discloses a double-effect catalytic ozonation wastewater treatment device and method. The wastewater treatment device comprises a heterogeneous catalytic ozonation reactor. The heterogeneous catalytic ozonation reactor is provided with a water inlet and a water outlet and is connected with an ozone generator through an ozone pipeline. The wastewater treatment device further comprises an ultraviolet catalytic ozonation reactor which comprises a water inlet and a water outlet. The water inlet pipe of the ultraviolet catalytic ozonation reactor is connected with the water outlet of the heterogeneous catalytic ozonation reactor. The ultraviolet catalytic ozonation reactor comprises an ultraviolet lamp light source arranged in the reactor. The double-effect catalytic ozonation wastewater treatment device has the advantages that the device is deep in wastewater treatment degree, free of secondary pollution and low in treatment cost.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

Zinc oxide method treatment process for sulfur dioxide waste gas

InactiveCN109985509AFine granularityHigh activityGas treatmentDispersed particle separationLead smeltingPre washing

The invention discloses a zinc oxide method treatment process for sulfur dioxide waste gas, and belongs to the field of treatment of sulfur dioxide waste gas. The proposed scheme comprises the following steps: collecting crude zinc oxide, and collecting crude zinc oxide produced in a fuming furnace for lead smelting, performing alkali elution on the collected crude zinc oxide so as to remove fluorine and chlorine, arranging a pre-washing tower at the front end of an absorption tower so as to eliminate influences of organic matter and impurities in flue gas on production of a subsequent wet-method zinc-smelting system, performing high pressure air oxidation on a zinc sulfite mixed solution, inserting an aeration tube into the zinc sulfite mixed solution, blowing compressed air into the aeration tube with the blown air pressure of 0.03-0.08 Mpa, and oxidizing zinc sulfite so as to produce a zinc sulfate solution under a forced oxidation atmosphere. The desulfurization efficiency can reach 95% or above, the emission concentration of SO2 is kept stable at 100 mg / Nm<3> or below, and the operating cost of the system is low; and only the operating cost of devices is required, and no costof desulfurization agents is generated.

Owner:ANHUI TONGGUAN NONFERROUS METALS (CHIZHOU) CO LTD

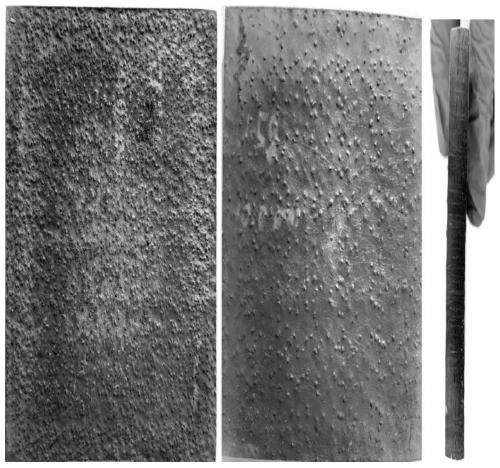

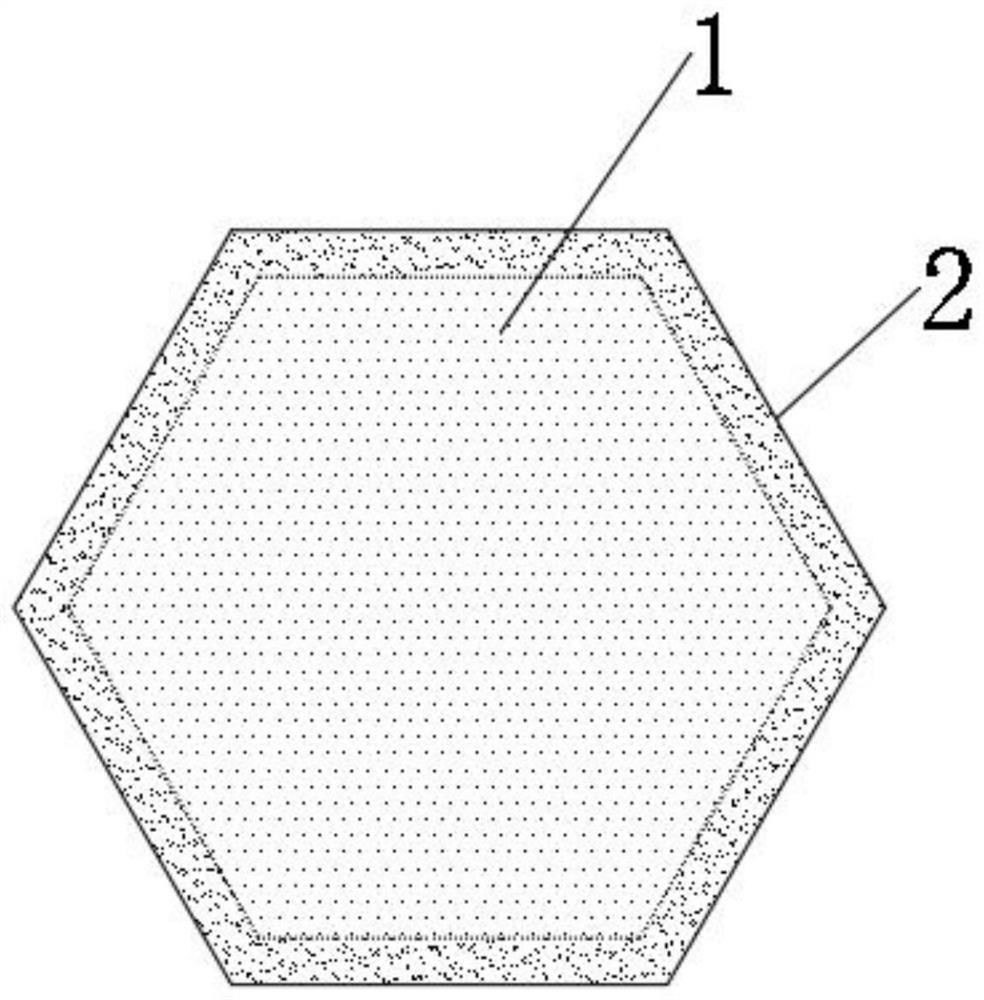

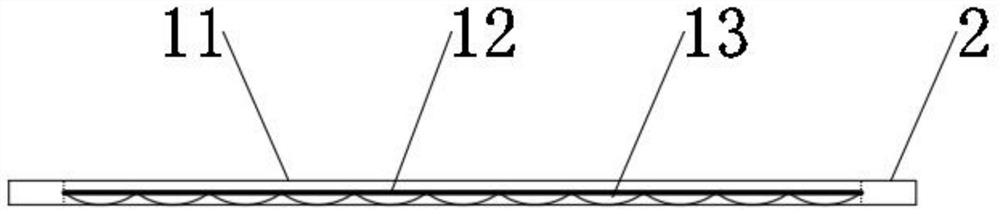

Nanoporous antioxidant resin-based composite material and preparation method thereof

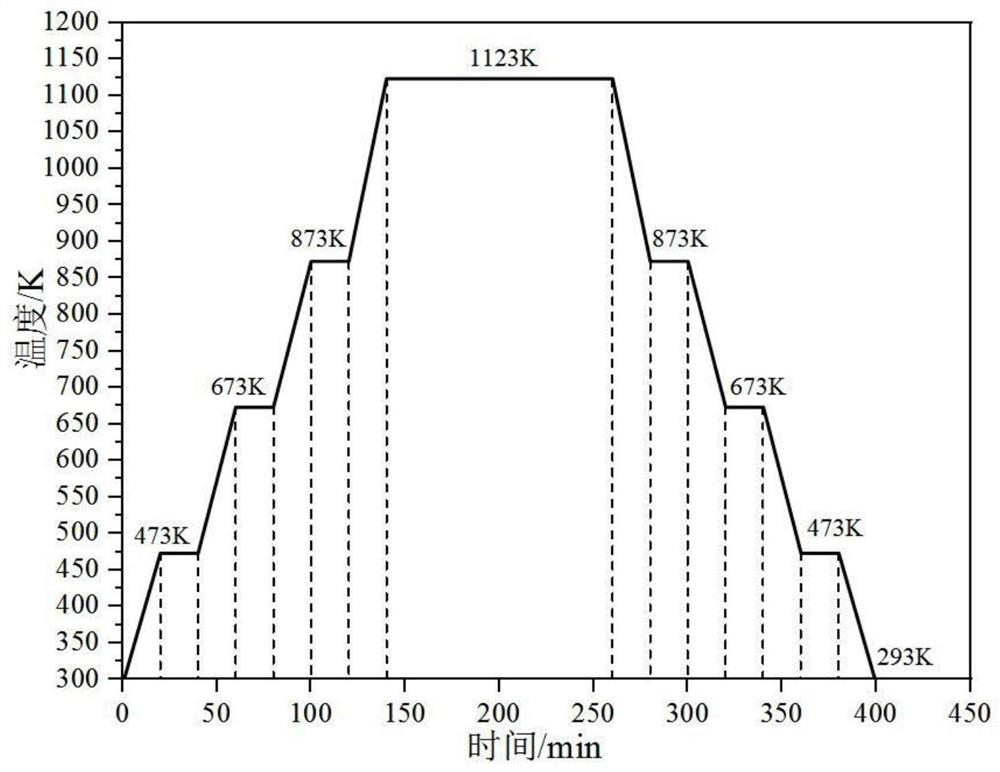

The invention relates to a nanoporous antioxidant resin-based composite material and a preparation method thereof. The composite material comprises the following components by mass: 20-80 wt% of antioxidant resin and 20-80 wt% of a reinforcer. The preparation method comprises the steps: (1) preparation of an antioxidant resin solution; (2) low-pressure RTM impregnation; (3) a sol-gel reaction; and(4) drying to finally obtain the composite material. Compared with the prior art, the composite material prepared by the invention has the advantages of light weight, high strength, excellent heat insulation property, ablation resistance, adjustable nanoparticle network structure and the like; through the synergistic effect of physical and chemical antioxidants, the oxidation resistance of a prepared matrix resin is greatly improved compared with the oxidation resistance of traditional resin, and the matrix resin has the advantages of good oxidation resistance in an environment with a temperature of 600-2000 DEG C and the like and can be widely applied to an external heat protection system of a hypersonic aircraft in an aerobic atmosphere.

Owner:EAST CHINA UNIV OF SCI & TECH

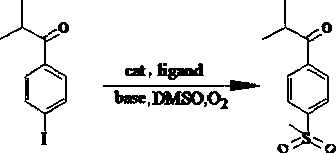

Preparation method of Firocoxib intermediate

ActiveCN107778204AAvoid harmEnvironmental protection of productionOrganic chemistryOrganic compound preparationChemical synthesisKetone

The invention discloses a preparation method of a Firocoxib intermediate. The preparation method belongs to the technical field of chemical synthesis. The preparation method comprises the steps: adding isobutyryl-containing aryl halide, a catalyst, a ligand and thin alkali into an organic solvent at an air or oxygen atmosphere, raising the temperature to carry out a reaction for 10-20h, and then,carrying out aftertreatment to prepare 2-methyl-1-[4-(methylsulfonyl)phenyl]propane-1-ketone. According to the preparation method, isobutyryl-containing aryl halide is used as a reaction raw material,so that a high-yield target product can be obtained; in addition, compound raw materials such as thioether or sulfoxide capable of generating great environmental hazards are avoided from being adopted, so that the production is environment-friendly, meanwhile, few reaction steps are required, few side reactions are generated, and the purity and yield of a product are high.

Owner:YANGZHOU TIANHE PHARM CO LTD

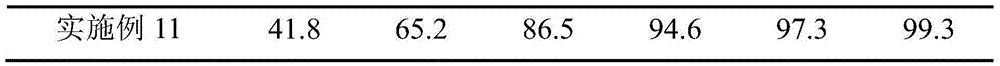

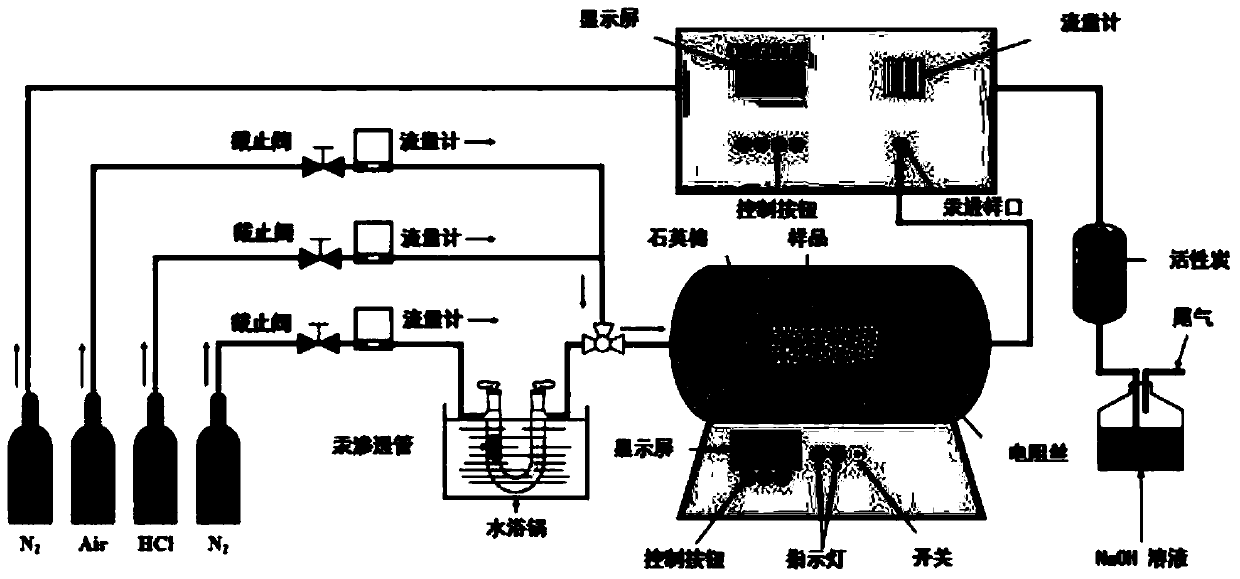

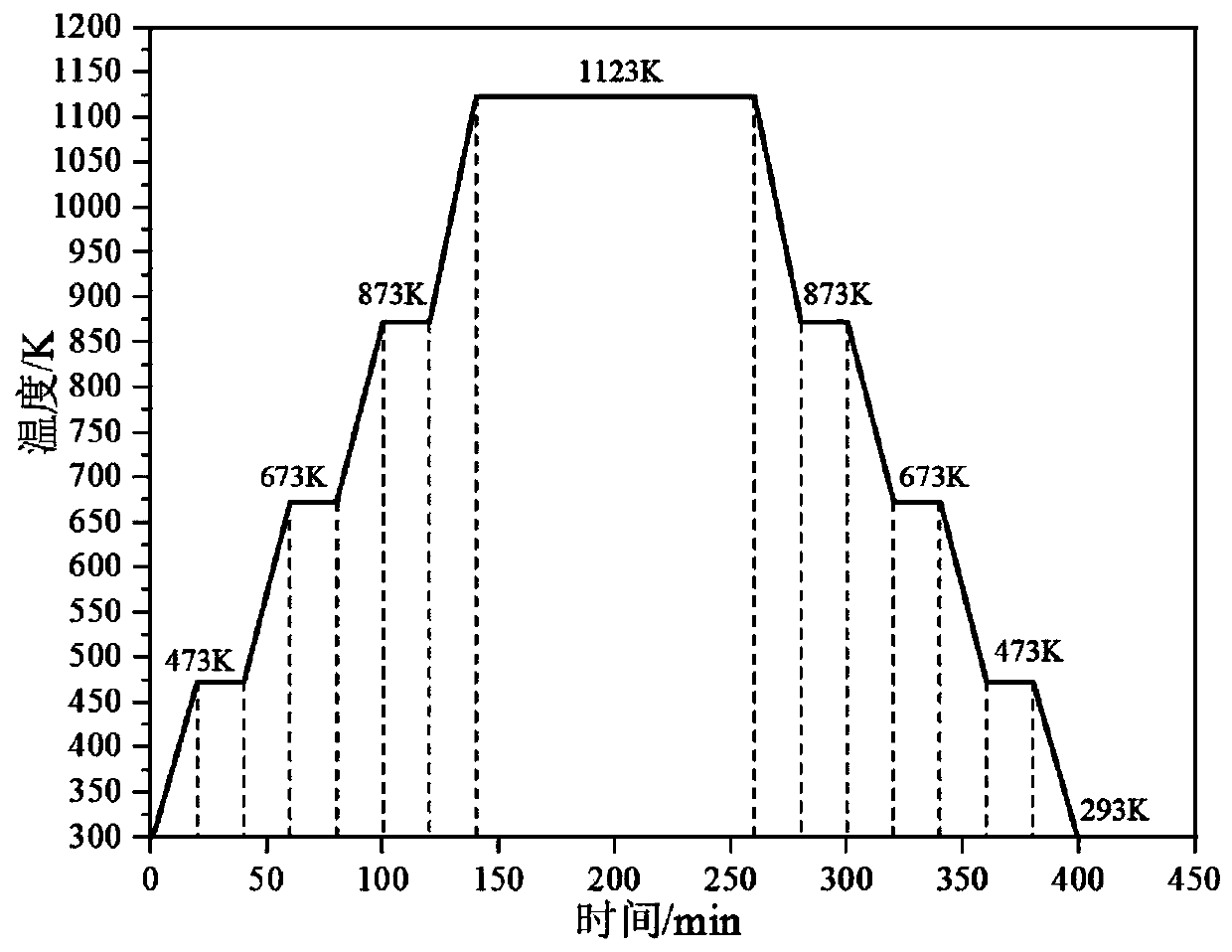

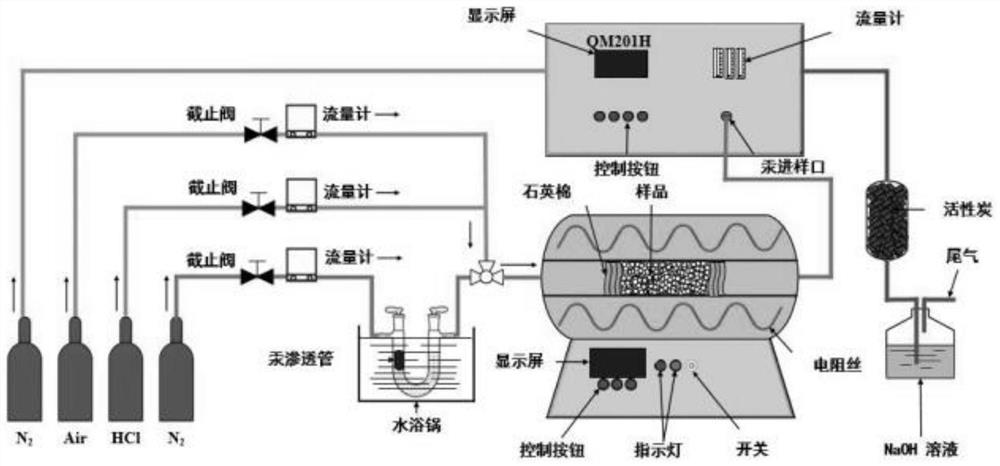

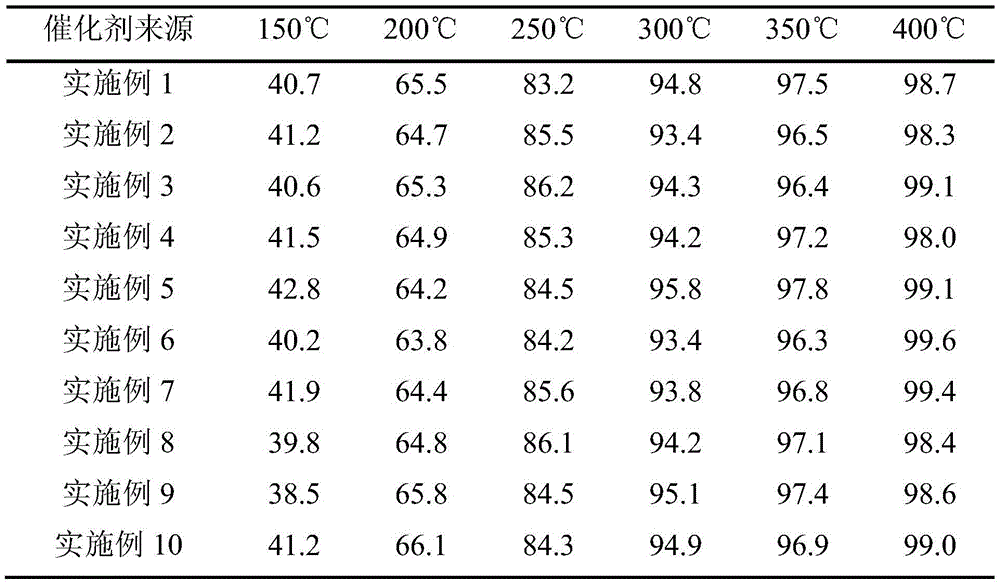

Cerous phosphate based catalyst for zero-valent mercury oxidation, preparation method and applications thereof

ActiveCN104399499ARaw materials are readily availableEasy to operatePhysical/chemical process catalystsDispersed particle separationPhosphateCerium

The invention discloses a cerous phosphate based catalyst for zero-valent mercury oxidation. The catalyst is mainly composed of cerous phosphate, and comprises modification components; wherein the modification components are composed of at least one oxide of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum, tin, and the like. The invention also discloses a preparation method and applications of the catalyst. The preparation process is simple, and the operation is convenient. Compared to the prior art, the catalyst has the following advantages: (1) the active components of the catalyst are all common metal oxides, the common metal phosphate is taken as the carrier, the raw materials are simple and easily available, and the operation is convenient; (2) the catalyst has a very good sulfur-resistant performance; (3) the CePO4 catalyst, which has been modified by metal oxides, is well adapt to the flue gas. The provided catalyst can fully utilizes the NO in flue gas to greatly promote the oxidation of zero-valent mercury. The great dependence on HCl of conventional catalysts is gotten rid of.

Owner:ZHEJIANG UNIV

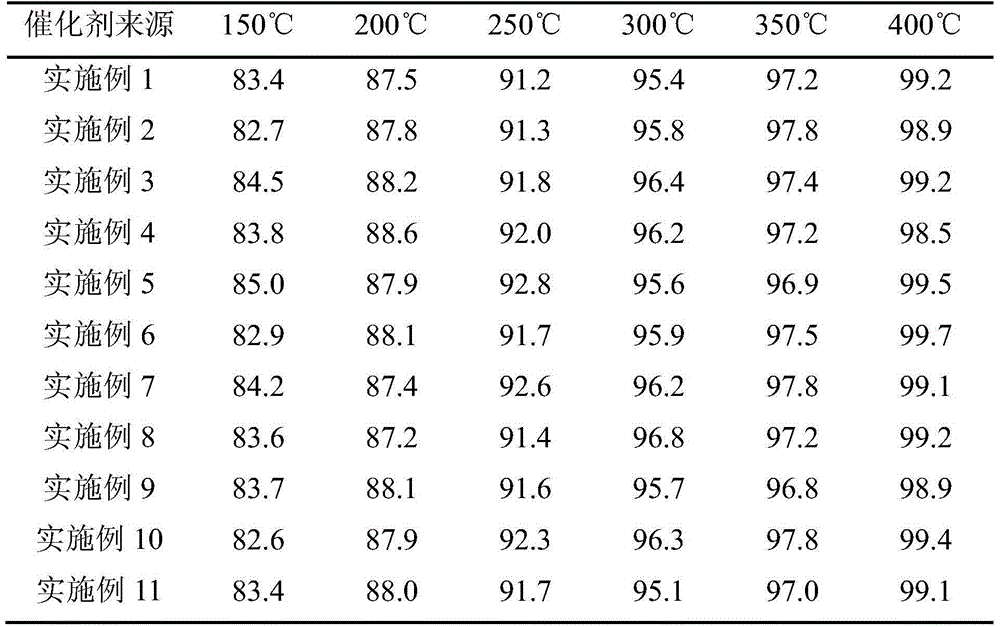

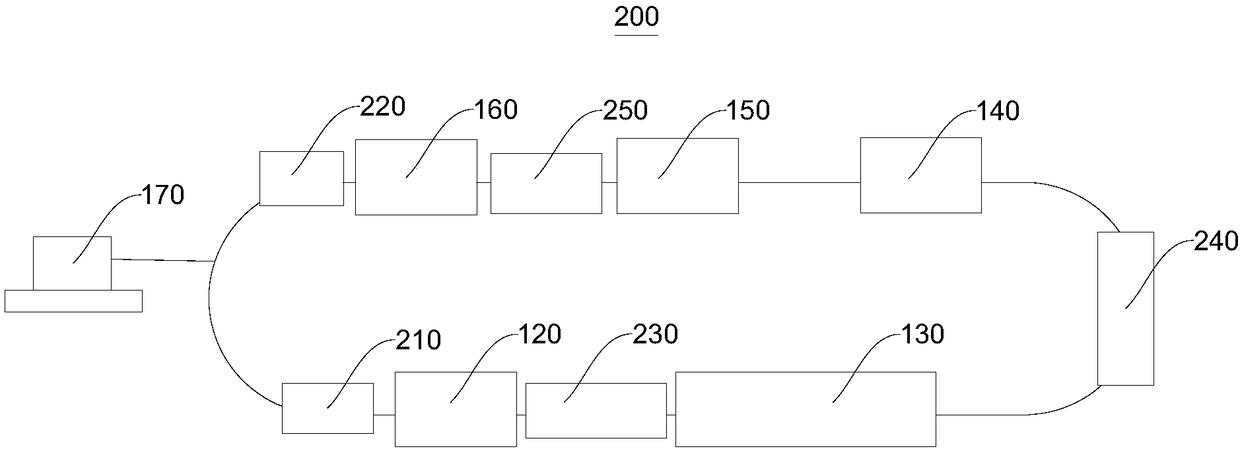

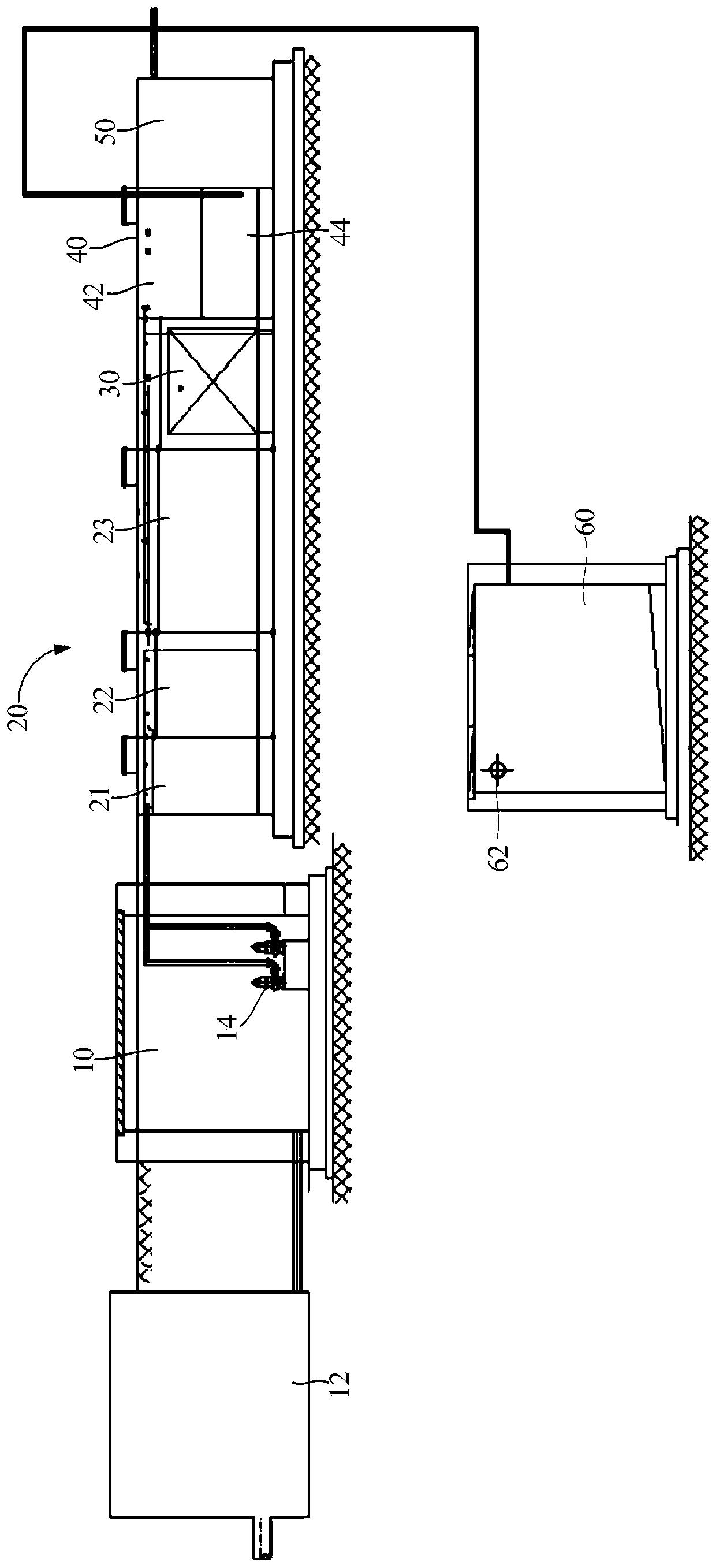

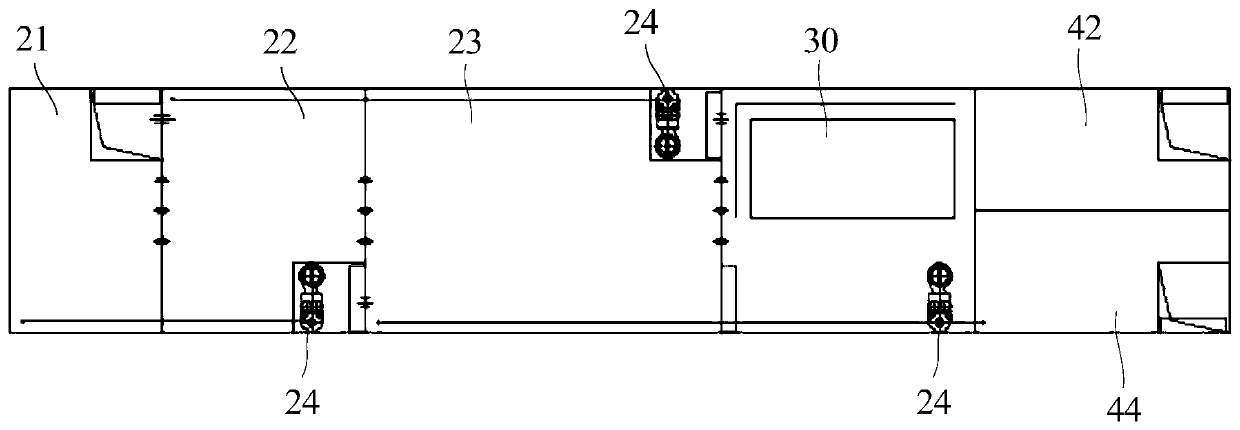

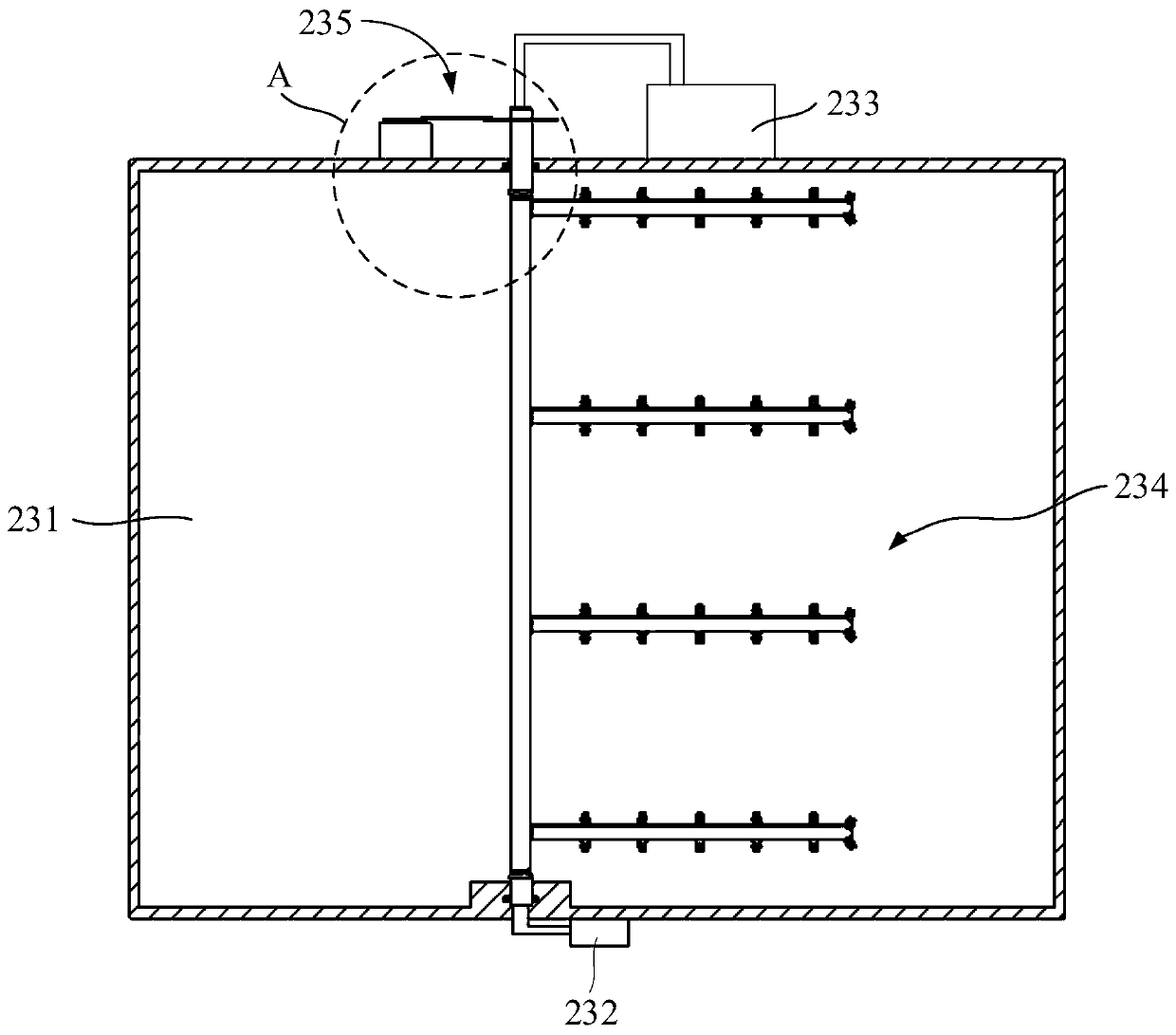

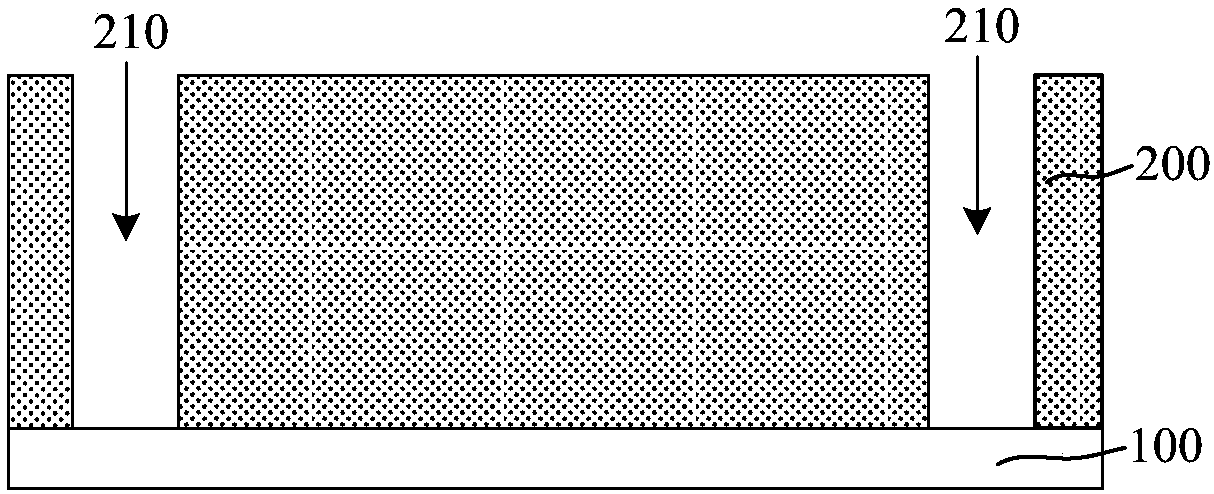

Continuous oxidation treatment system and method

InactiveCN108149294ARealize continuous processingShorten the timeSurface reaction electrolytic coatingElectrode ContactMechanical engineering

The invention provides a continuous oxidation treatment system and a continuous oxidation treatment method, and belongs to the technical field of light metal surface treatment. The continuous oxidation treatment system comprises an annular conveying device, an oxidation tank which is used for holding an electrolyte, and a conductive row which is matched with electrode contacts in a moving processof hanging tools; the conveying device is provided with a plurality of hanging tools; the hanging tools are used for fixing a part to be machined; and the electrode contacts are arranged on the hanging tools. The conveying device comprises a first conveying section, a descending section and an ascending section which are positioned above the oxidation tank; the descending section and the ascendingsection are respectively connected to a front end and a rear end of the first conveying section in a conveying direction so that the part to be machined enters the oxidation tank gradually when the part to be machined moves to the descending section along with the conveying device, and leaves away the oxidation tank gradually when the part to be machined moves to the ascending section; and the conductive row is arranged between the first conveying section and the oxidation tank. The system is simple in structure; the oxidation period is shortened; the production efficiency is high; and the energy consumption is reduced.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

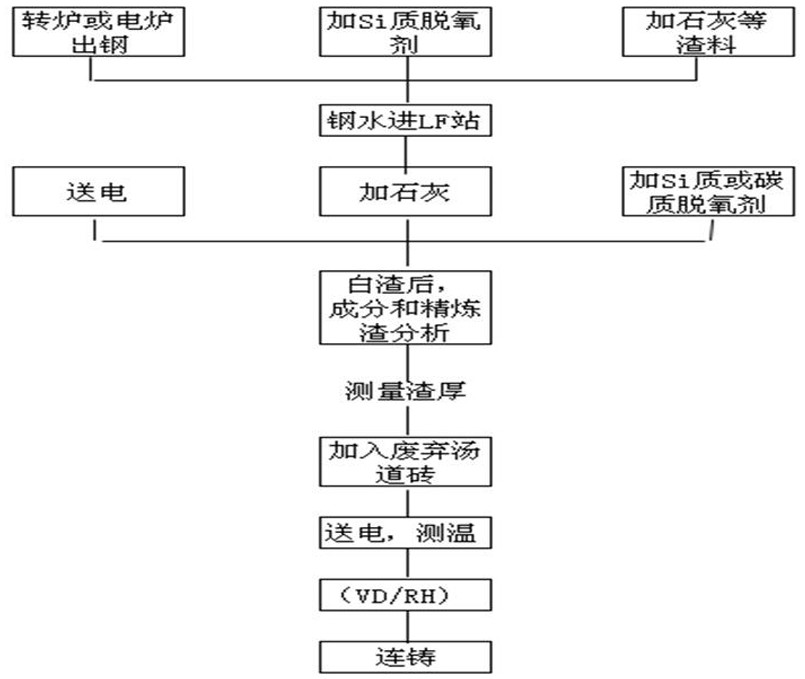

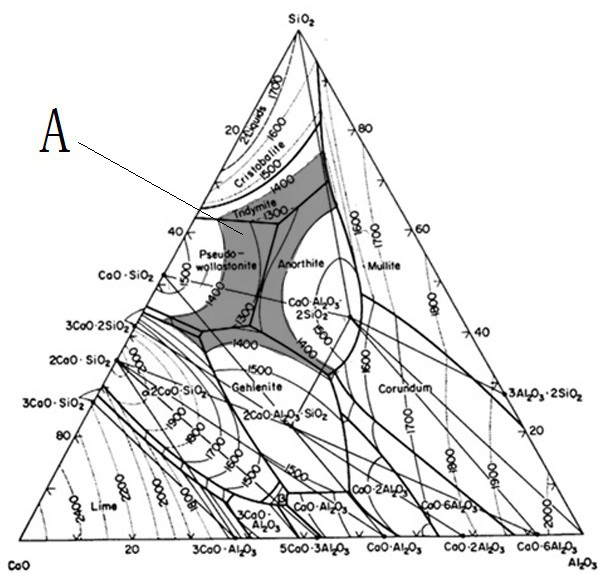

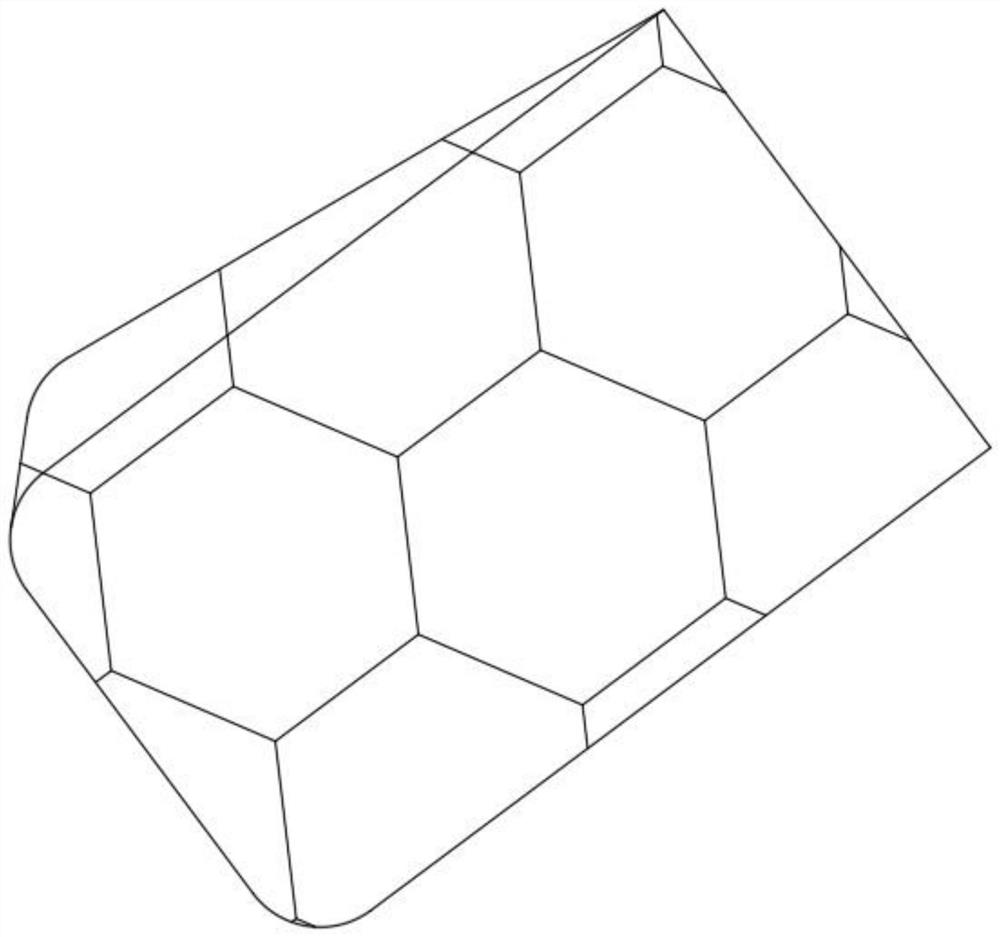

Method for producing high-quality steel through abandoned cast steel bricks

InactiveCN111621618AIncrease power consumptionExtend the production cycleManufacturing convertersBrickSlag

The invention discloses a method for producing high-quality steel through abandoned cast steel bricks. The method includes the following steps that firstly, converter high-carbon-catch tapping is conducted; secondly, in the tapping process, a siliceous deoxidizing agent, lime slag charge and alloys are added; thirdly, LF furnace refining is conducted; fourthly, white slag post component and refining slag analysis is conducted; fifthly, according to refining slag components, furnace slag components are adjusted to a CaO-SiO2-Al2O3 ternary phase diagram area A through the abandoned cast steel bricks; sixthly, component adjustment and soft blowing are conducted, components are adjusted to regulated values according to steel sample components, and according to the refining slag components, theslag components are adjusted to the CaO-SiO2-Al2O3 ternary phase diagram area A through the abandoned cast steel bricks; seventhly, argon blowing processing is conducted, the vacuum degree is smallerthan or equal to 100 Pa, and the vacuum keeping time is not shorter than 15 min; and eighthly, continuous casting is conducted. The method effectively overcomes the defects that an existing method inthe current industry is high in cost, high in electricity consumption, long in production period and not capable of achieving circulation.

Owner:MINMETALS YINGKOU MEDIUM PLATE

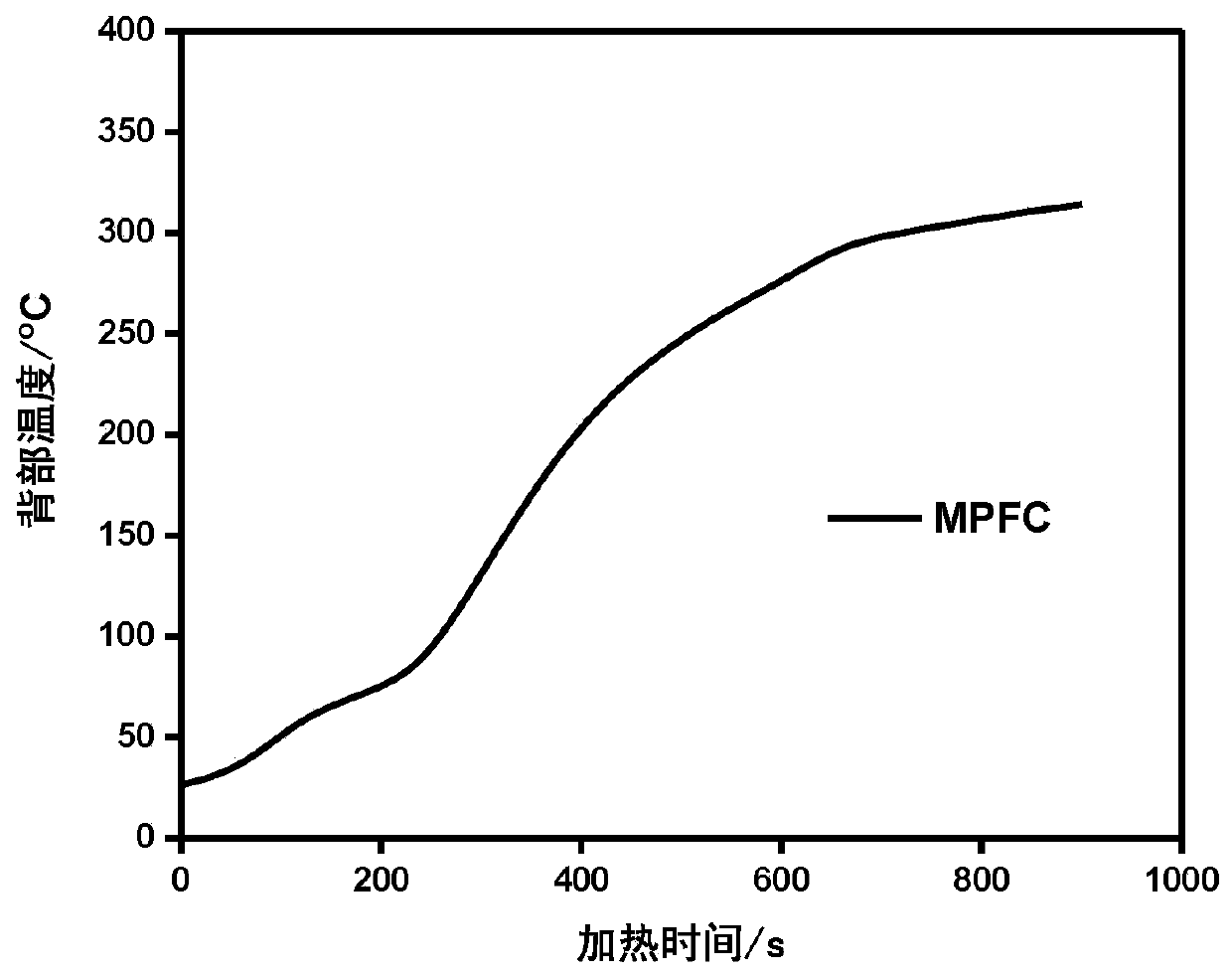

Preparation method of packaging bag capable of being quickly degraded

InactiveCN113150396AImprove thermal oxidation effectImprove degradation efficiencyFlexible coversWrappersThin membraneChemistry

The invention discloses a preparation method of a packaging bag capable of being rapidly degraded, and belongs to the technical field of packaging bags. A raw material formula can be improved based on a light-biological combined degradation mode, meanwhile, degradation-assisting scales are introduced in the film forming process, the degradation-assisting scales can be autonomously combined into a dense state, meanwhile, the outer surface of a thin film is protected, and normal use is not interfered. After being scrapped, the plastic packaging bag enters the natural environment, the degradation-assisting scales can be partially dissolved under the action of water and are changed into net-shaped gaps from the original dense state, the plastic packaging bag can enter the interior of the packaging bag under the action of external light, and the back faces of the degradation-assisting scales convert light energy into heat energy after absorbing the light energy. Meanwhile, oxygen release is accelerated, the thermal oxidation effect is improved, in addition, the external biodegradation effect is matched, the degradation efficiency of the packaging bag can be remarkably improved, and the decomposition period is shortened.

Owner:方龙

Landfill leachate bioreactor based on modified fiber filler

InactiveCN114605031AEvenly distributedImprove the effect of direct contactSpecific water treatment objectivesMultistage water/sewage treatmentFiberZizania aquatica

The landfill leachate bioreactor comprises a reaction box, a water outlet in the lower portion of the right side of the reaction box is fixedly connected with the water inlet end of a lifting pump, and the water inlet end of the lifting pump is fixedly connected with a water inlet of an electrolytic treatment device. According to the landfill leachate bioreactor based on the modified fiber filler, a water inlet pipe is connected with a leachate outlet pipe, a driving motor II drives a rotary water injection pipe to rotate through the rotary water injection pipe, and a flow equalizing pipe rotates along with the rotary water injection pipe, so that leachate in the flow equalizing pipe can be discharged downwards through a drainage hole while the flow equalizing pipe rotates; the flow equalizing pipe is changed from static leachate discharge to rotary residual filtrate discharge, so that the position of the flow equalizing pipe is in a continuously changing state, and the leachate is more uniformly and comprehensively distributed when entering the reaction box; further, the filter material is in full and comprehensive contact with the upper layer modified zizania aquatica shell fiber filter material structure and the lower layer coconut shell fiber filter material structure.

Owner:ZHEJIANG SHUREN UNIV

Cleaning solution convenient for workpiece cleaning

The invention relates to a cleaning solution convenient for workpiece cleaning. The cleaning solution comprises, by weight, 24.28-25.67% of a cleaning agent, 4.59-5.37% of sodium nitrite, 1.75-2.28% of sodium hydroxide, 0.87-1.14% of thiourea as an oxidizing agent, 1.69-2.36% of trisodium phosphate and 63.18-66.82% of water. The cleaning solution comprising the cleaning agent, sodium nitrite, sodium hydroxide, thiourea as an oxidizing agent, trisodium phosphate and water is used for cleaning a workpiece so that an antirust layer is formed on the surface of the workpiece. Through cooperation of thiourea as an oxidizing agent and sodium hydroxide, oxidation performances in mixing are guaranteed, cleaning efficiency is improved, the workpiece does not fade, use performances and a service life are improved, a chrome plating process on the workpiece is avoided, a production cost is reduced, production efficiency is improved, safety and reliability are obtained, workpiece quality after cleaning is guaranteed and follow-up production processes are convenient.

Owner:湖州卓瑞刀具科技有限公司

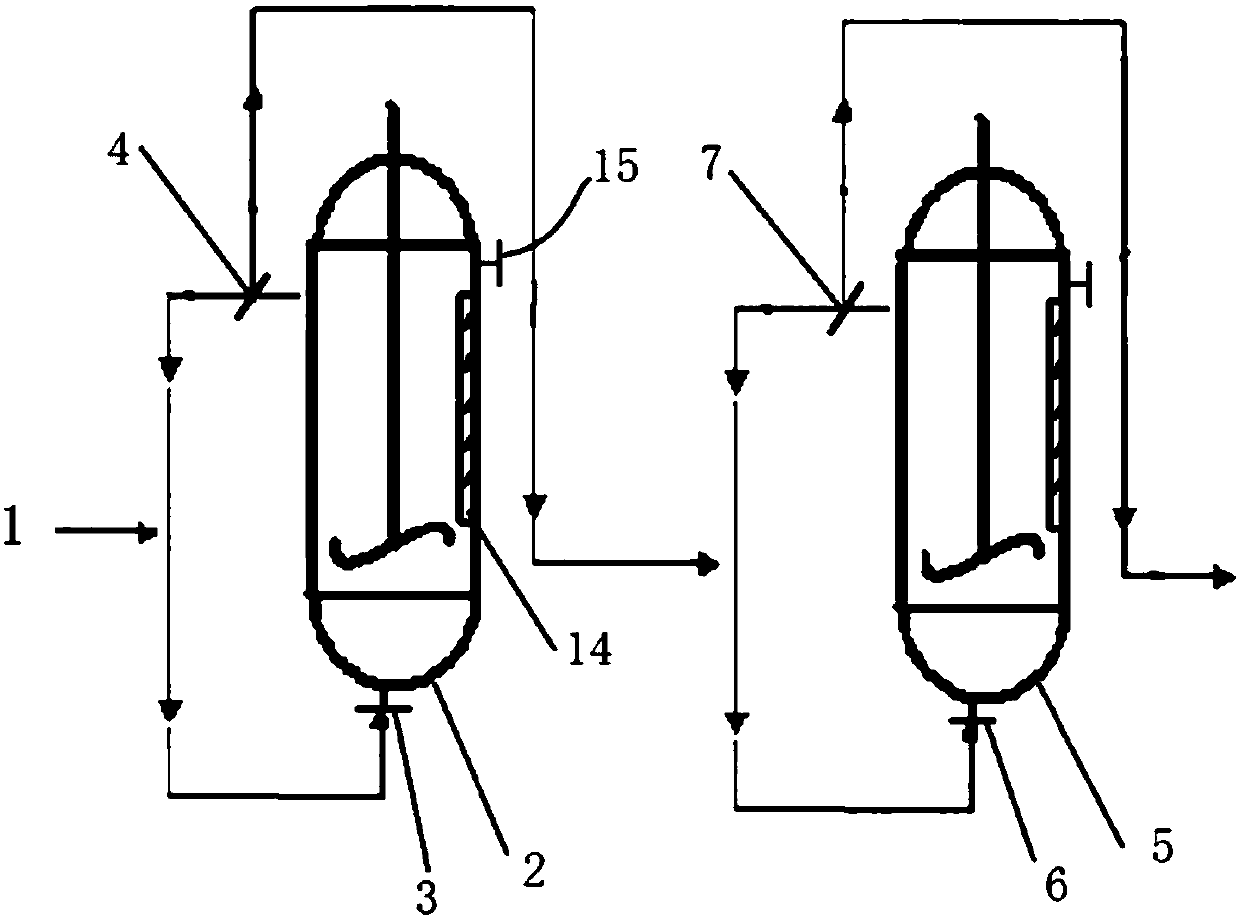

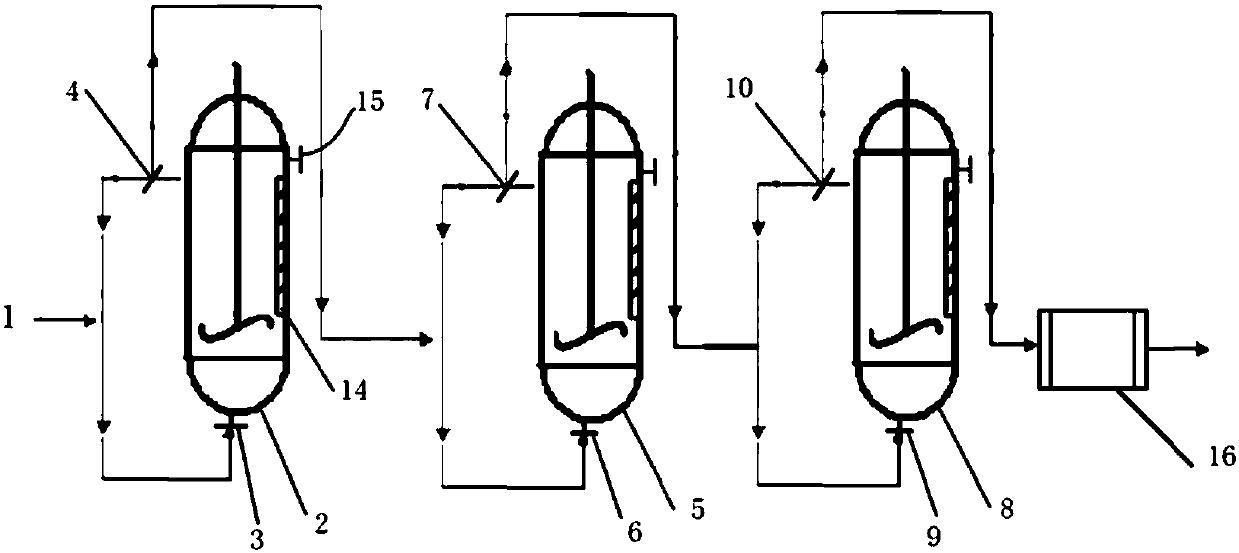

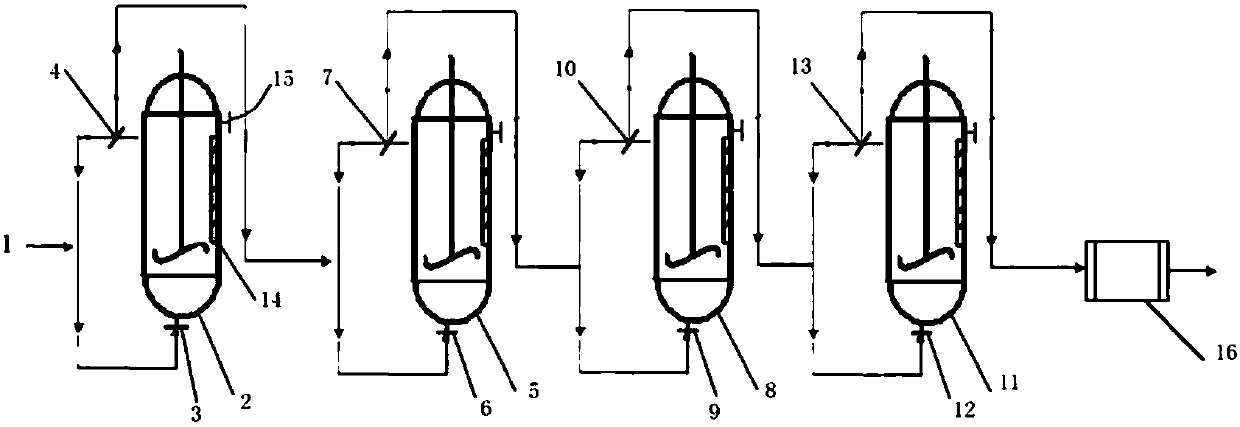

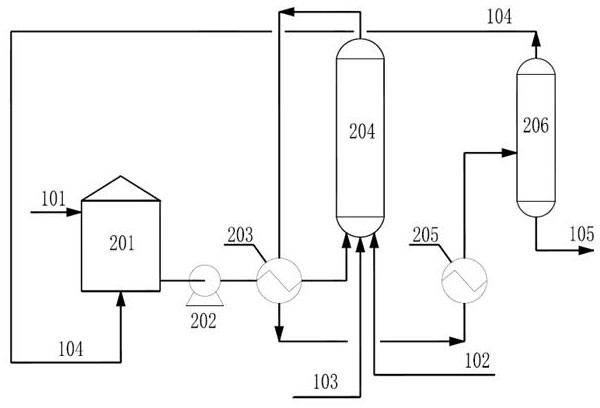

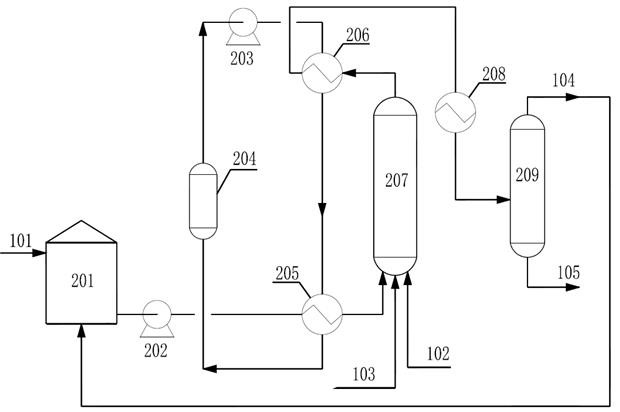

A method and system for removing organic impurities in salt-making brine

InactiveCN106745077BIncrease the degree of mixingGuaranteed oxidation effectAlkali metal halide purificationWater/sewage treatment by oxidationFenton reactionEnvironmental resistance

The invention discloses a method and system for removing organic impurities from salt manufacturing brine. The method comprises the following steps: regulating the pH value of the salt manufacturing brine to be 1-6, then enabling the salt manufacturing brine after pH value regulation to enter a first-stage reactor of a reaction system formed by series connection of at least two stages of reactors, wherein discharged materials of each stage of reactor are divided into cycle materials and net discharged materials, enabling the cycle materials of all stages of reactors except the last-stage reactor to return and enter the corresponding-stage reactor, and enabling the net discharged materials to enter the next-stage reactor; and adding an oxidizer and a catalyst to all stages of reactors, performing a reaction under UV irradiation, finally enabling the cycle materials of the last-stage reactor to return and enter the corresponding-stage reactor, regulating the pH value of the net discharged materials of the last-stage reactor to be neutral, and performing filtration so as to obtain purified brine. Through the adoption of the method, the application of a Fenton reagent in the purification field of low-concentration organic aqueous solutions is realized, the technical problem that a Fenton reaction can only be in intermittent production is solved, and the method has the characteristics of being good in impurity removal effect, large in treatment capacity, safe and environment-friendly, and realizing continuous production.

Owner:HENAN UNIV OF URBAN CONSTR

Method and device for treating ethylene waste lye

PendingCN114684953AAvoid cloggingGuaranteed uptimeWater treatment parameter controlSpecific water treatment objectivesFluid phaseProcess engineering

The invention relates to a method and a device for treating ethylene waste lye, the ethylene waste lye enters a gas floating unit for treatment, is conveyed to a heat exchange unit after treatment, enters a wet oxidation unit after heat removal, and is in contact with oxygen-containing gas under the pressure condition of keeping the solution in a liquid phase for wet oxidation reaction; the oxidized material is returned to the heat exchange unit to preheat the waste alkali liquid, the material after heat exchange is cooled and decompressed and then enters the gas-liquid separation unit, and the gas phase after gas-liquid separation is returned to the air floatation unit. According to the characteristics of the ethylene waste alkali liquor, reaction heat is utilized to the maximum extent, and meanwhile, the problems that heat exchange equipment is blocked due to thermal polymers in the long-term operation process, and local overtemperature is generated in the wet oxidation process can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

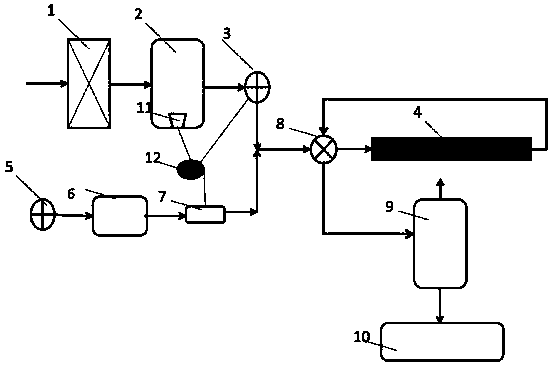

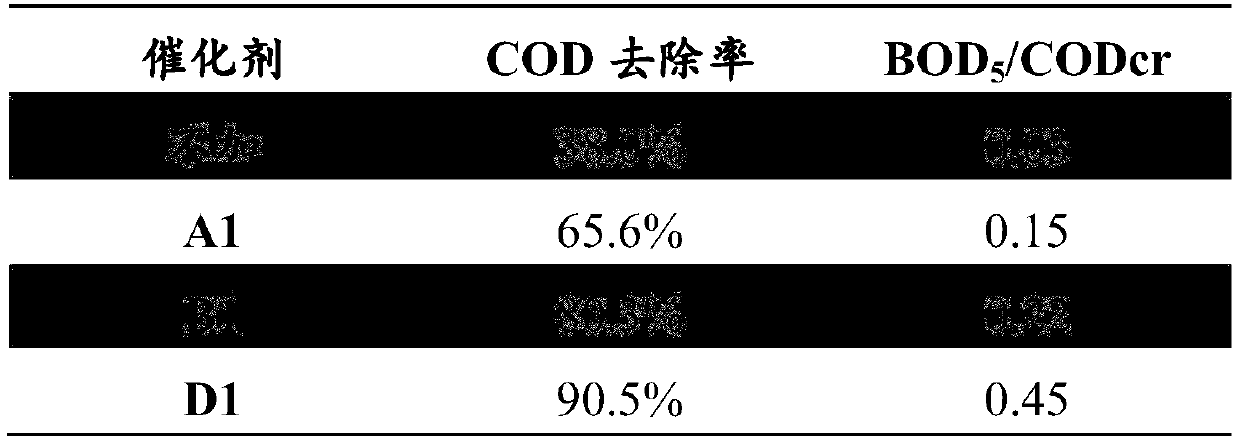

Assistant wastewater treatment process

ActiveCN110386692AGuaranteed tubular free radical oxidation effectGuaranteed oxidation effectMolecular sieve catalystsWater treatment compoundsLiquid storage tankCatalytic effect

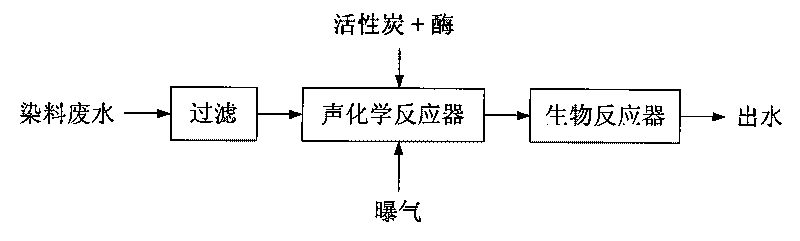

The invention provides an assistant wastewater treatment process. A tubular continuous reaction device is adopted, the device includes a filter, a sewage buffer tank, a sewage pump, a free radical generator, an air compressor, an air buffer tank, an air flow meter, a heat exchanger, a high-pressure separation tank and a liquid storage tank, the sewage flow is controlled by using a composite catalyst and monitoring the sewage concentration by arranging a sewage concentration detection device, the tubular free radical oxidation effect of assistant wastewater is guaranteed, the catalytic effect can still be guaranteed when the process is applied to the assistant wastewater with a wide range of concentration fluctuation, continuous operation for 100 hours is conducted, the average removal rateof CODcr is 95% or above, and BOD5 / CODcr after treatment is greater than 0.6.

Owner:福泉环保城发展有限公司

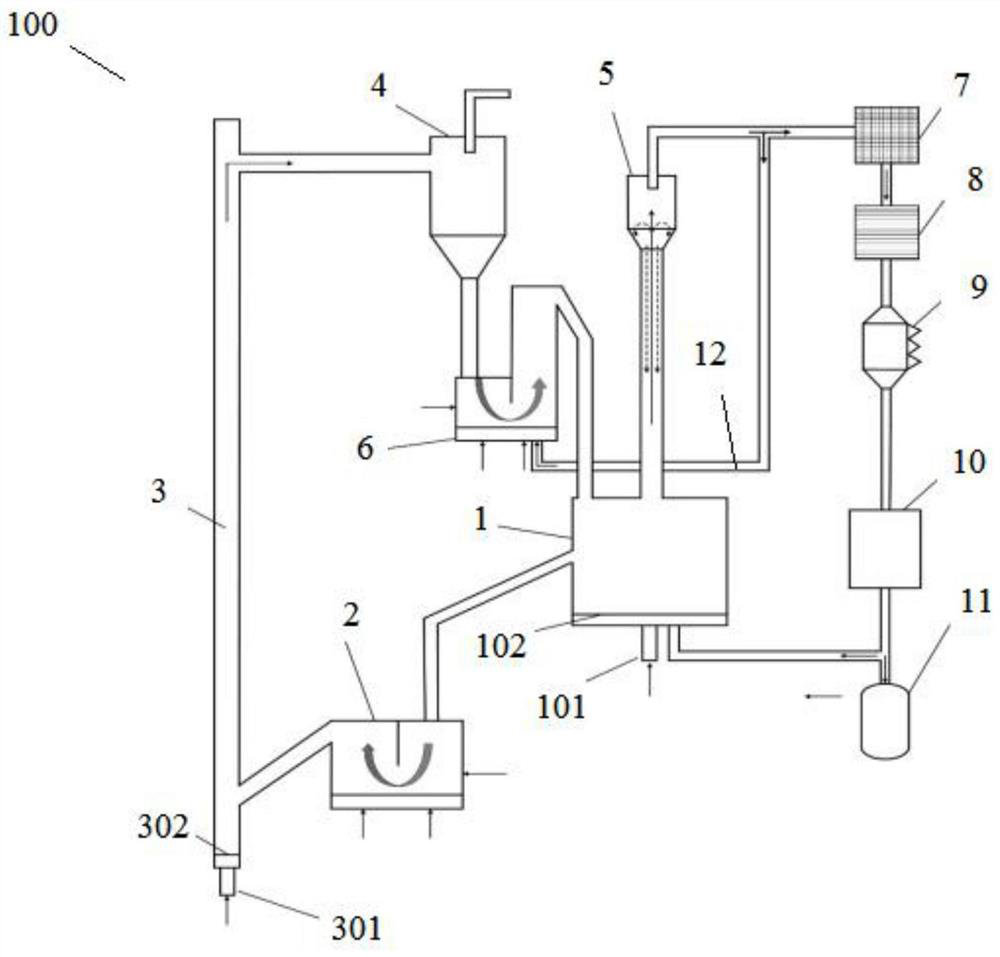

Coal chemical looping combustion mercury removal device and method

ActiveCN111001292AIncrease oxidation rateImprove conversion and capture efficienciesGas treatmentDispersed particle separationProcess engineeringFlue gas

The invention provides a coal chemical-looping combustion mercury removal device. The coal chemical-looping combustion mercury removal device comprises a fuel reactor; a fuel reactor U-phase valve which is connected with the fuel reactor; an air reactor which is connected with the fuel reactor U-phase valve; an air cyclone separator which is connected with the air reactor; a flue gas cyclone separator which is connected with the fuel reactor; an air reactor U-phase valve which is simultaneously connected with the air cyclone separator, the flue gas cyclone separator and the fuel reactor; a condenser is connected with the flue gas cyclone separator; a SCR denitration device which is connected with the condenser; a flue gas dust remover which is connected with the SCR denitration device; a wet flue gas desulfurizer which is connected with the flue gas dust remover; and a CO2 catcher which is connected with the wet flue gas desulfurizer. The invention further provides a coal chemical-looping combustion mercury removal method based on the coal chemical-looping combustion mercury removal device. The mercury removal method is used for mercury removal of flue gas generated by combustion.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A coal chemical looping combustion mercury removal device and method

ActiveCN111001292BEasy accessIncrease oxidation rateGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention provides a coal chemical looping combustion mercury removal device, comprising: a fuel reactor; a U-phase valve of the fuel reactor connected to the fuel reactor; an air reactor connected to the U-phase valve of the fuel reactor; an air cyclone separator , connected to the air reactor; the flue gas cyclone separator, connected to the fuel reactor; the U-phase valve of the air reactor, connected to the air cyclone separator, the flue gas cyclone separator and the fuel reactor at the same time; the condenser, connected to the flue gas Cyclone separator connection; SCR denitrifier, connected to condenser; flue gas dust collector, connected to SCR denitrifier; wet flue gas desulfurizer, connected to flue gas dust collector; and CO 2 The collector is connected with the wet flue gas desulfurizer. The invention also provides a mercury removal method based on a coal chemical chain combustion mercury removal device to remove mercury from flue gas generated by combustion.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

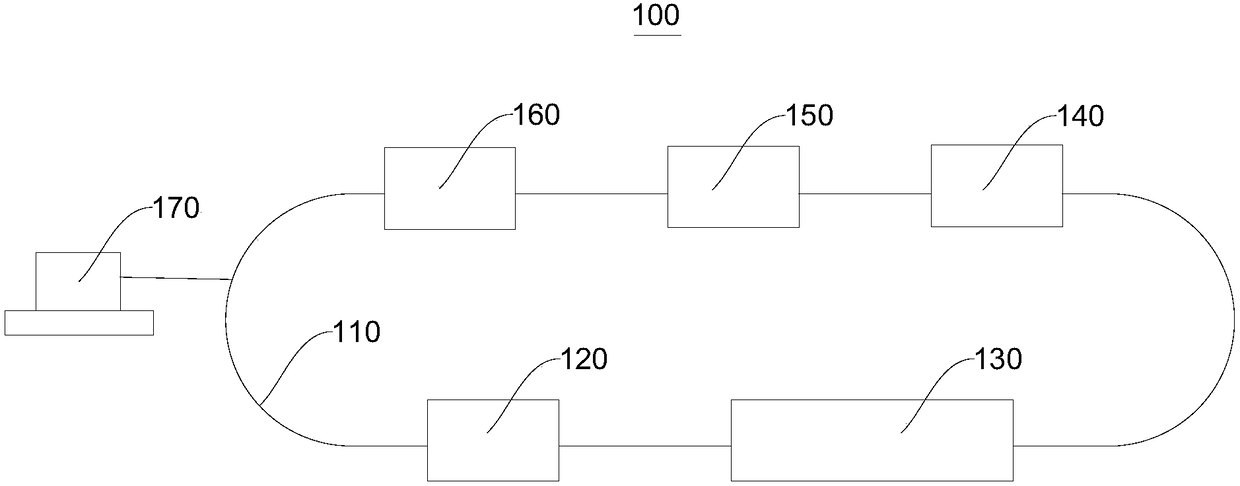

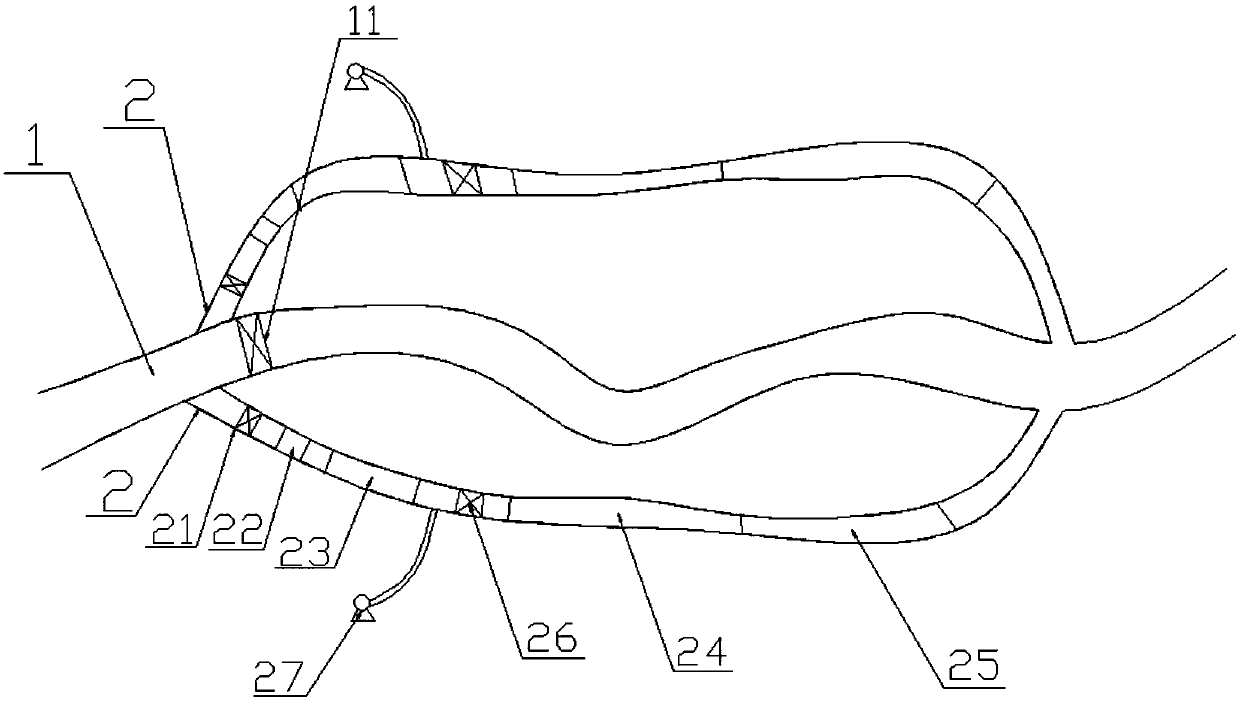

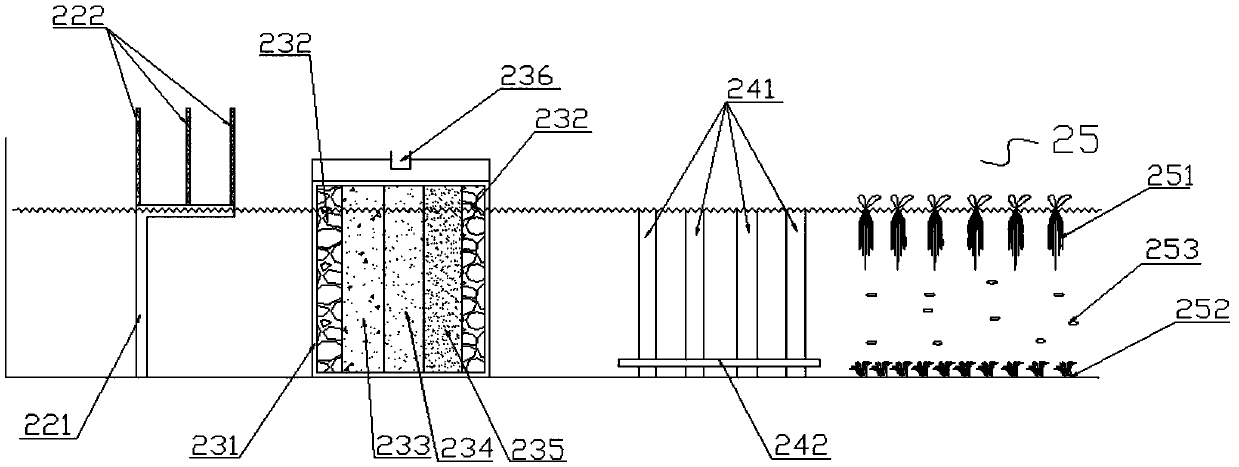

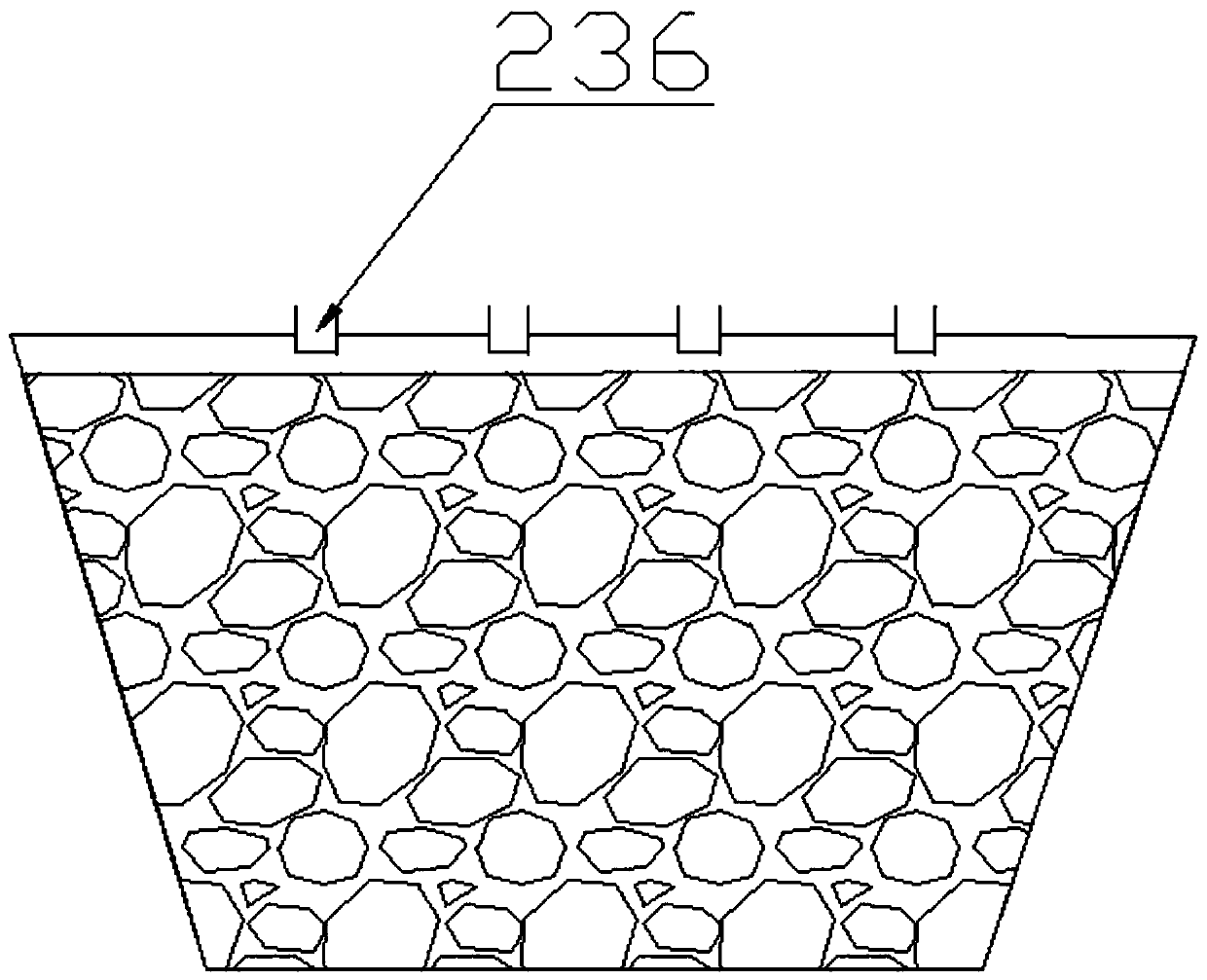

River channel ecological management project

InactiveCN109650654AWill not affect normal circulationWill not affect normal travelWater aerationTreatment involving filtrationWater flowEngineering

The invention discloses a river channel ecological management project. A river channel includes an original river channel and a purified river channel; one end of the original river channel is a starting point, and the other end of the original river channel is a terminal point; the two ends of the purified river channel are respectively connected to the starting point and terminal point of the original river channel; the original river channel and purified river channel are respectively provided with an original valve and a first purifying valve at the starting point; the purified river channel is successively provided with a water flow mitigation device, a filter bed, a microbial oxidation section and an ecological treatment area along a bank in the river channel from the purifying valveto a downstream direction; and the upstream of the original river channel is provided with the purified river channel, the split purification of water from the upstream can be performed through the controlling of a gate, so that the normal circulation of the original river channel and the normal travelling of residents living on the two sides of the river channel cannot be affected.

Owner:FLOWER KING ECO ENG CO LTD

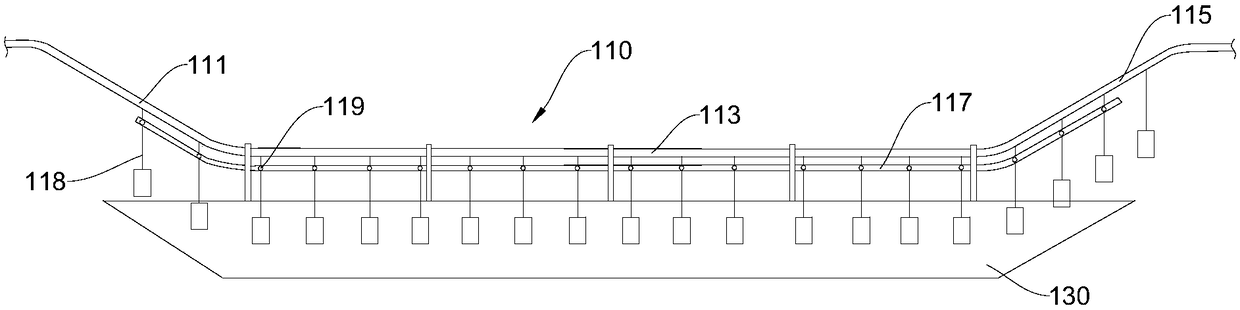

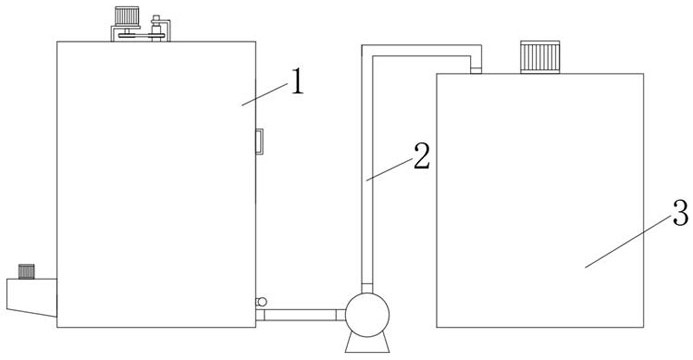

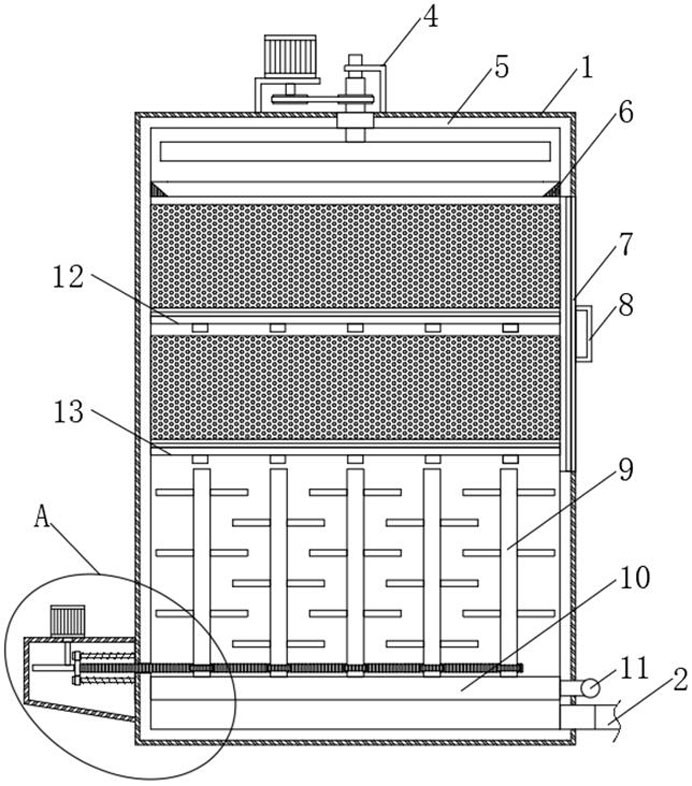

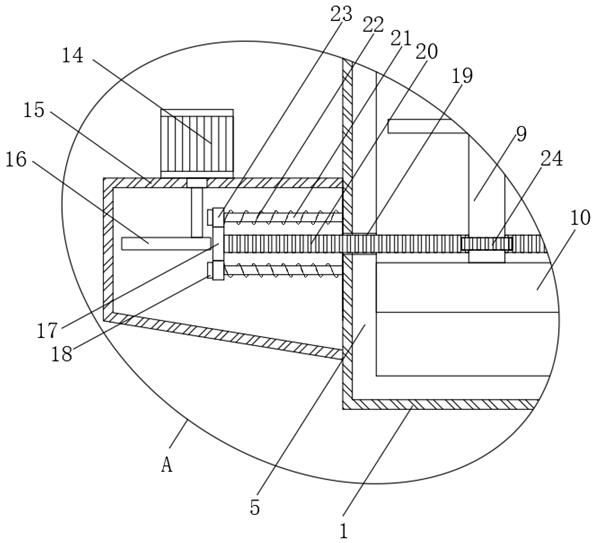

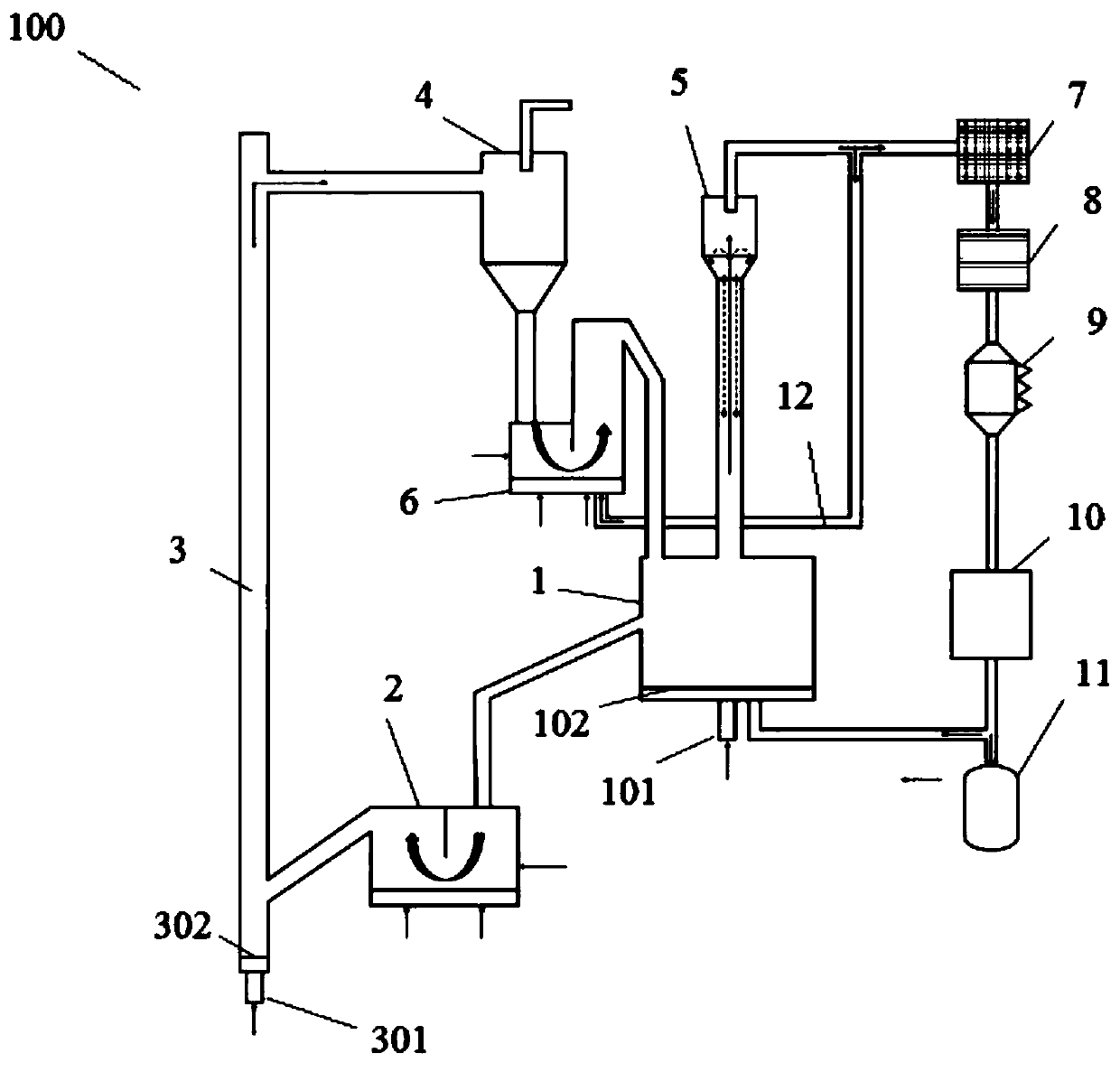

Integrated sewage treatment device

InactiveCN110902830AGuaranteed treatment effectGuaranteed oxidation effectWater treatment parameter controlTreatment with aerobic and anaerobic processesSludgeOxidation pond

The invention discloses an integrated sewage treatment device. The integrated sewage treatment device comprises an adjusting pool, a contact oxidation pool, a membrane pool and a sludge pool which areconnected in sequence, wherein the contact oxidation pool comprises an anaerobic pool, an anoxic pool and an aerobic pool which are connected in sequence; the anaerobic pool is connected with the adjusting pool; the aerobic pool is connected with the membrane pool; the aerobic pool comprises a pool body, an aerator, an oxygen supply machine, an air injection assembly and a driving mechanism; theair injection assembly comprises a rotating pipe, aeration pipes and oxygen supply pipes; and the driving mechanism is connected with the rotating pipe to drive the rotating pipe to rotate, so the aeration pipes and the oxygen supply pipes swing. The above-mentioned integrated sewage treatment device provided by the invention has the following advantages: the rotating pipe is provided with a plurality of aeration pipes and oxygen supply pipes along an axial direction; the aeration pipes can spray out air; the oxygen supply pipes can spray out oxygen; the driving mechanism can drive the aeration pipes and the oxygen supply pipes to swing; thus, sewage at all depths in the aerobic pool can be in full contact with the air and the oxygen; the oxidation effect of the aerobic pool is guaranteed;and the treatment effect of sewage is guaranteed.

Owner:重庆振冉环保技术开发有限公司

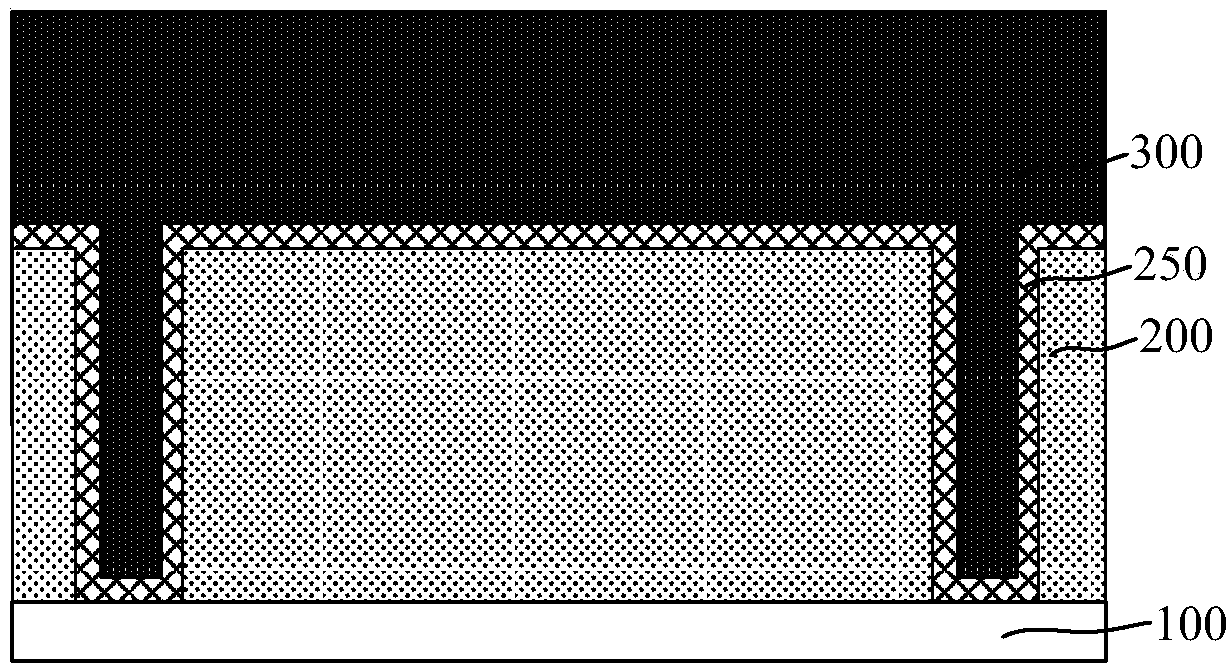

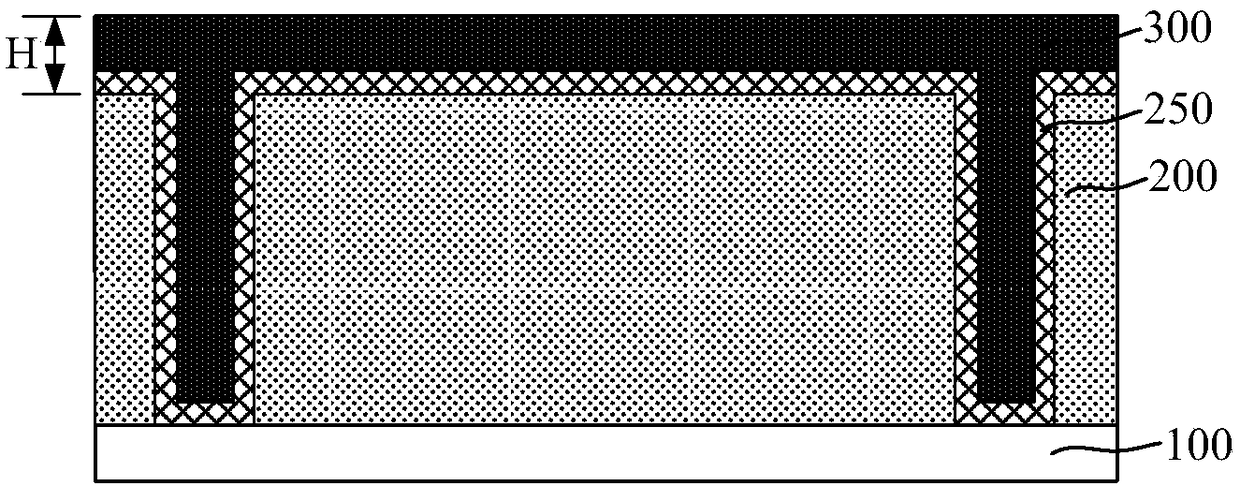

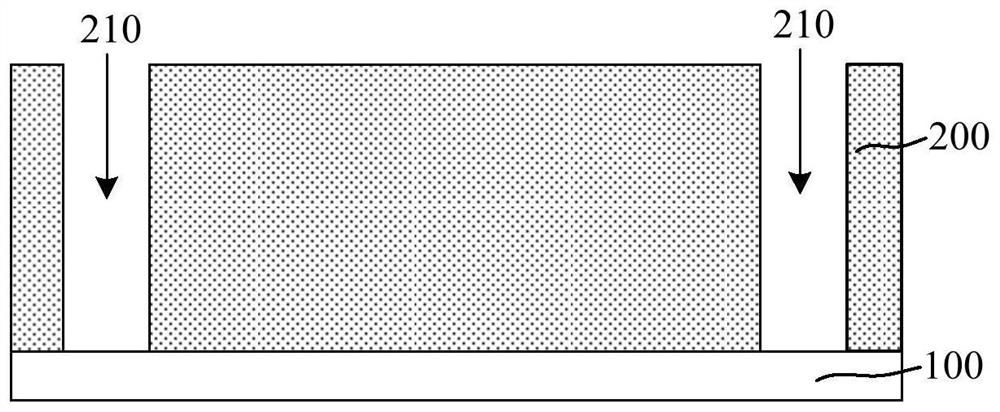

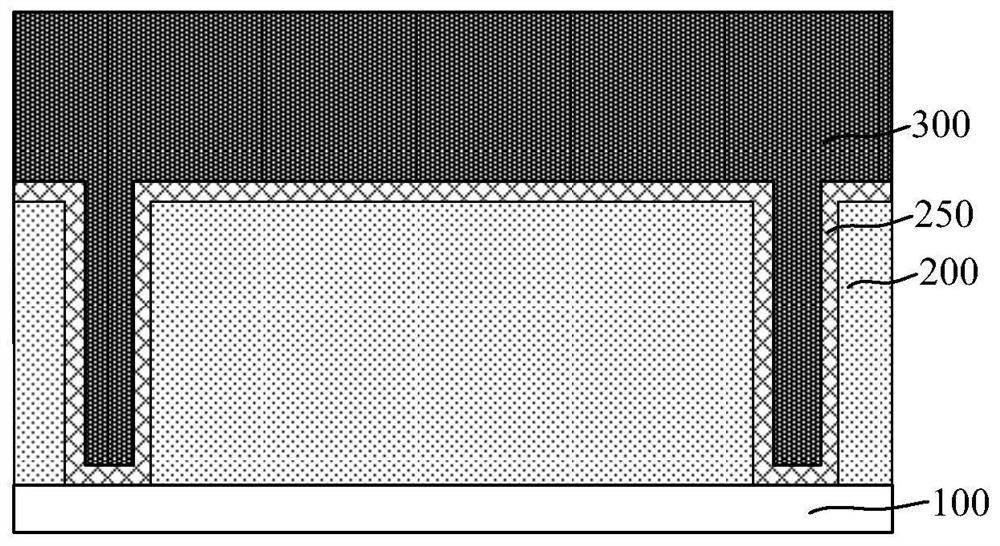

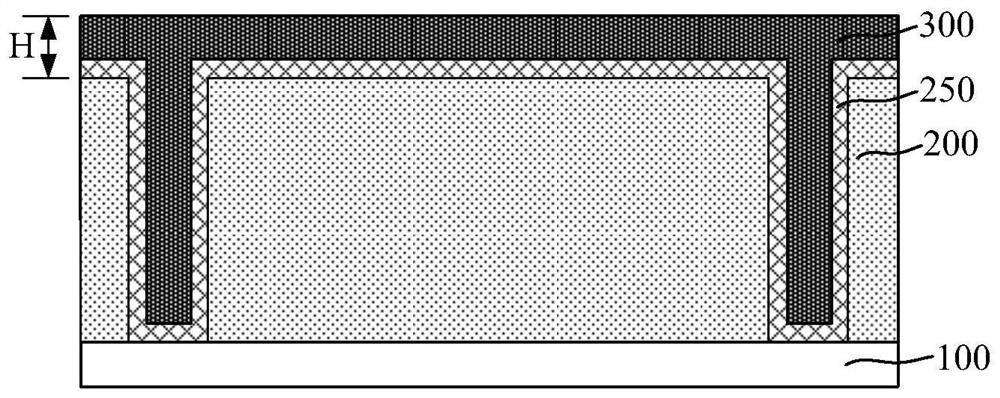

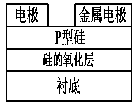

Semiconductor structure, and formation method thereof

ActiveCN108962740AImprove grinding qualityImprove electrical performanceSemiconductor/solid-state device manufacturingLapping machinesSemiconductor structureCobalt

The invention provides a semiconductor structure, and a formation method thereof. The formation method of the semiconductor structure includes the steps: a cobalt layer is formed; the cobalt layer isplanarized by a chemical mechanical grinding process, and the grinding lubricant utilized by the chemical mechanical grinding process is a weakly alkaline grinding lubricant; and the solutions utilized by the cleaning operation and the conveying operation in the chemical mechanical grinding process are all weakly alkaline solutions. The formation method of the semiconductor structure adopts the weakly alkaline grinding lubricant, and the solutions utilized by the cleaning operation and the conveying operation in the chemical mechanical grinding process are weakly alkaline solutions, so that compared with a scheme of performing the cleaning operation and the conveying operation by using an acidic grinding lubricant and deionized water, the formation method of the semiconductor structure canimprove the problem of corrosion of the cobalt layer so as to improve the grinding quality of the cobalt layer to improve the electrical properties of the semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor structures and methods of forming them

ActiveCN108962740BImprove grinding qualityImprove electrical performanceSemiconductor/solid-state device manufacturingLapping machinesMetallurgySemiconductor structure

A semiconductor structure and a forming method thereof, the forming method comprising: forming a cobalt layer; planarizing the cobalt layer by using a chemical mechanical polishing process, wherein the polishing liquid used in the chemical mechanical polishing process is a weakly alkaline polishing liquid; Wherein, the solutions used in the cleaning operation and the conveying operation in the chemical mechanical polishing process are weakly alkaline solutions. The present invention adopts weakly alkaline grinding liquid, and the solutions used in the cleaning operation and conveying operation in the chemical mechanical grinding process are all weakly alkaline solutions, compared with the use of acid grinding liquid and deionized water for the cleaning operation And the solution of the transmission operation, the present invention can improve the corrosion problem of the cobalt layer, thereby improving the grinding quality of the cobalt layer, and further improving the electrical performance of the semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of cobalt-based Fischer-Tropsch fixed bed catalyst for biomass synthesis gas and preparation method thereof

InactiveCN103638943BHigh activityHigh hydrothermal stabilityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSyngasFixed bed

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Cerium phosphate-based catalyst for zero-valent mercury oxidation, preparation method and application

ActiveCN104399499BRaw materials are readily availableEasy to operatePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses a cerous phosphate based catalyst for zero-valent mercury oxidation. The catalyst is mainly composed of cerous phosphate, and comprises modification components; wherein the modification components are composed of at least one oxide of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum, tin, and the like. The invention also discloses a preparation method and applications of the catalyst. The preparation process is simple, and the operation is convenient. Compared to the prior art, the catalyst has the following advantages: (1) the active components of the catalyst are all common metal oxides, the common metal phosphate is taken as the carrier, the raw materials are simple and easily available, and the operation is convenient; (2) the catalyst has a very good sulfur-resistant performance; (3) the CePO4 catalyst, which has been modified by metal oxides, is well adapt to the flue gas. The provided catalyst can fully utilizes the NO in flue gas to greatly promote the oxidation of zero-valent mercury. The great dependence on HCl of conventional catalysts is gotten rid of.

Owner:ZHEJIANG UNIV

Application of tellurium-based composite film as SOI (Semiconductor On Insulator) material and SOI power device

InactiveCN102522365BGuaranteed oxidation effectExcellent characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricHigh resistance

The invention discloses an application of a tellurium-based composite film as an SOI (Semiconductor on Insulator) material. The tellurium-based composite film is of a composite film structure formed in a manner that TeO2 and / or Te are embedded among SiO2-containing particles to form Te / TeO2-SiO2. The tellurium-based composite film is applied to an SOI device, and a Schottky diode device which is of an SOI structure taking the tellurium-based composite film as a silicon insulation layer is manufactured. The test research proves that the tellurium-based composite film has the characteristics of high resistance property, smaller dielectric constant, high forbidden band width, high critical breakdown electrical field, high electron mobility and the like, and becomes an ideal insulation material for manufacture of the SOI device. According to the invention, the problem on the SOI insulation layer is solved, and the application field of the tellurium-based composite film is developed.

Owner:CHONGQING UNIV

Aluminum alloy surface anti-corrosion treatment method

InactiveCN110938854AAffect the oxidation effectGuaranteed oxidation effectAnodisationMetallurgyElectric machinery

The invention discloses an aluminum alloy surface anti-corrosion treatment method which comprises the following steps: a, sequentially carrying out dust removal and drying treatment on aluminum alloyto obtain a product a1; b, placing the product a1 in a roller polishing machine with a motor rotating speed ranging from 80 r / min to 90 r / min, adding a polishing agent for polishing treatment for 50 min, and obtaining a product b1; c, washing and degreasing the product b1 to obtain a product c1; d, washing the product c1 with water and carrying out alkaline etching treatment to obtain a product d1; e, washing the product d1 with deionized water, and oxidizing an electrode to obtain a product e1; and f, sealing holes of the product e1 to obtain finished aluminum alloy. The method has the advantages that the oxidation electrolyte is not polluted, and the pass percentage of the product is higher.

Owner:湖州市漾西电化有限公司

Ethylene waste alkali liquor treatment method and treatment device

PendingCN114684955AAvoid cloggingAvoid foulingWater treatment parameter controlSpecific water treatment objectivesFluid phaseProcess engineering

The invention relates to a method and a device for treating ethylene waste lye, the ethylene waste lye is treated by an air flotation unit and then enters a first heat exchanger of a heat exchange unit, and the waste lye after heat removal enters a wet oxidation unit and is in contact with oxygen-containing gas under the pressure condition that the solution is kept in a liquid phase to perform wet oxidation reaction; the reacted material enters a second heat exchanger of the heat exchange unit, the material subjected to heat exchange enters a gas-liquid separation unit after being cooled and decompressed, and the separated gas phase returns to the air flotation unit; the first heat exchanger and the second heat exchanger use the same heat exchange medium. According to the characteristics of the ethylene waste alkali liquor, the problems of blockage and scaling of heat exchange equipment, local overtemperature of the wet oxidation reactor and the like caused by long-term operation can be avoided while reaction heat is fully utilized and the operation energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for purifying yellow phosphorus by using methods of activated carbon adsorption together with dilute nitric acid rinsing

ActiveCN102107859BAdequate adsorption capacityImprove adsorption capacityPhosphorus compoundsHigh concentrationActivated carbon

The invention discloses a method for purifying yellow phosphorus by adopting methods of activated carbon adsorption together with dilute nitric acid rinsing. Firstly, activated carbon and molten industrial yellow phosphorus are mixed and stirred in a refining kettle, and after the adsorption is completed, the activated carbon is separated from the yellow phosphorus by a filter machine; then the processed yellow phosphorus is circularly rinsed with dilute nitric acid in an acid pickling tower; residual organic matters, arsenic and low-price metal ions in the yellow phosphorus, which are not adsorbed by the activated carbon, are oxidized by utilizing the oxidizability of the dilute nitric acid; and afterwards, the yellow phosphorus is circularly rinsed in a water washing tower by using deionized water, thereby completing yellow phosphorus purification. The invention adopts a process with treatment methods of activated carbon adsorption, dilute nitric acid rinsing and deionized water rinsing, and integrates the advantages of various methods; and the content of arsenic in the acquired yellow phosphorus is reduced to below 20 ppm, so that high-purity yellow phosphorus satisfying the requirement for producing electronic grade phosphoric acid can be acquired, and the hidden danger of explosion caused by using high concentration nitric acid is avoided.

Owner:湖北兴福电子材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com