Application of tellurium-based composite film as SOI (Semiconductor On Insulator) material and SOI power device

A technology for composite thin films and power devices, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and electrical components. Effects of Voltage and On-Current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

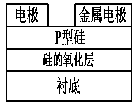

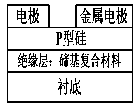

[0016] Application of a tellurium-based composite thin film as an insulating layer of an SOI device, the tellurium-based composite thin film contains SiO 2 The particles are embedded with TeO 2 and / or Te to form Te / TeO 2 - SiO 2 Composite thin film structure (for its preparation method refer to CN101838112A). Through experimental research, the resistivity of tellurium-based composite films reaches 1200Ω·m, the relative permittivity is less than 3.9, and the band gap is above 3.4eV, which proves that tellurium-based composite films have high resistance characteristics, small relative permittivity, and large Bandgap width, high critical breakdown electric field, and high electron mobility have become ideal insulating materials for SOI devices.

[0017] The tellurium-based composite thin film is applied to the SOI device, and the SOI structure Schottky diode device with the tellurium-based composite thin film as the silicon insulating layer is prepared. Such as figure 2 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com