Preparation method of magnetic graphene oxide and application thereof

A technology of stone oxide and graphene, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve unfavorable solid-liquid separation and adsorbent recovery, increase cost and energy consumption, and centrifugal separation Problems such as high energy consumption can achieve the effect of optimizing heating time, reducing preparation cost and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

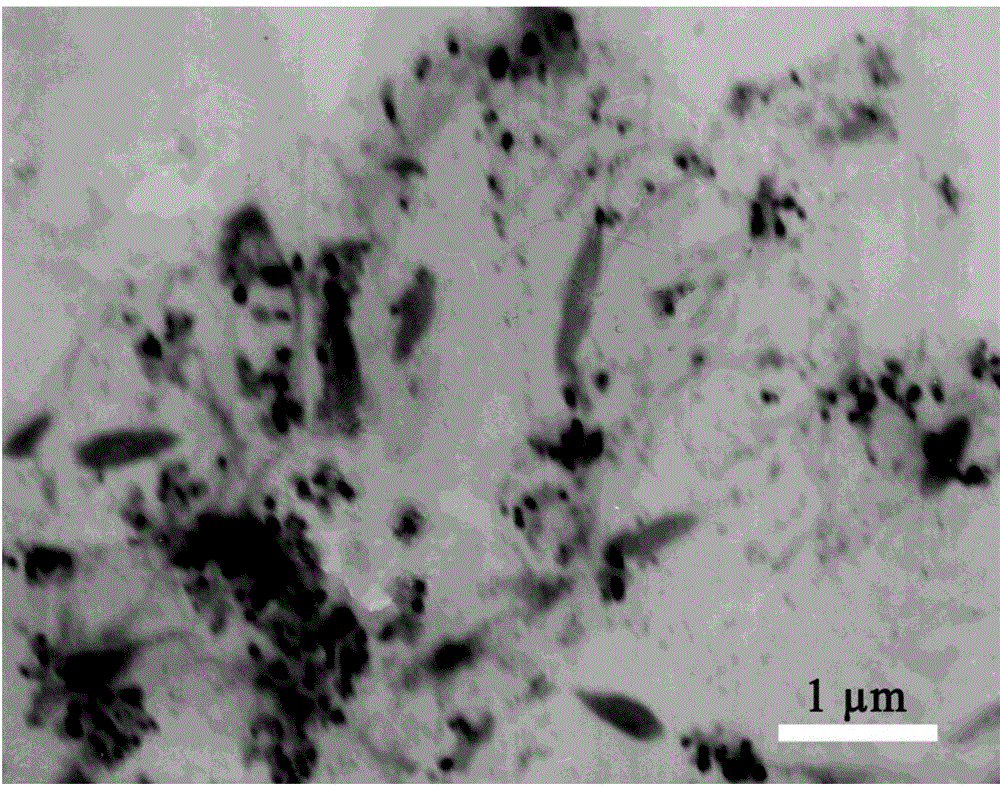

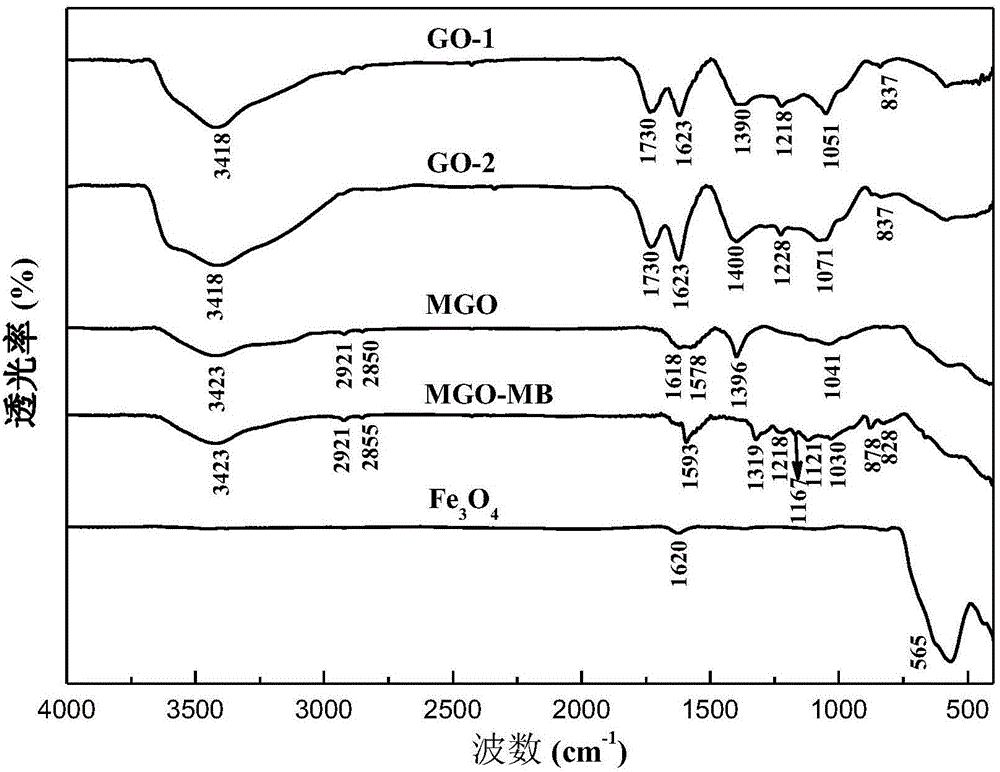

[0028] First prepare the magnetic adsorption material-magnetic graphene oxide according to the following process:

[0029] (1) Measure 46mL of concentrated sulfuric acid (mass concentration 98%) and concentrated phosphoric acid (mass concentration 85%) mixed solution with a volume ratio of 9:1, add 2.0g flake graphite powder in the mixed solution, place in a constant temperature magnetic stirrer Stir magnetically in an ice-water bath at 0°C for 30-60 minutes until uniform dispersion; slowly add 6.0g of potassium permanganate, and continue stirring for 30-60 minutes until the mixture is dark green; heat up to 35°C, and stir to react 60 minutes; raise the temperature to 60°C, add 98mL of deionized water continuously dropwise, raise the temperature to 98°C and stir for 30-60 minutes at a constant temperature; Concentration of 5% hydrochloric acid solution and 20mL of mass concentration of 5% hydrogen peroxide solution, the supernatant turned golden yellow, stirred for 30 minutes;...

Embodiment 2

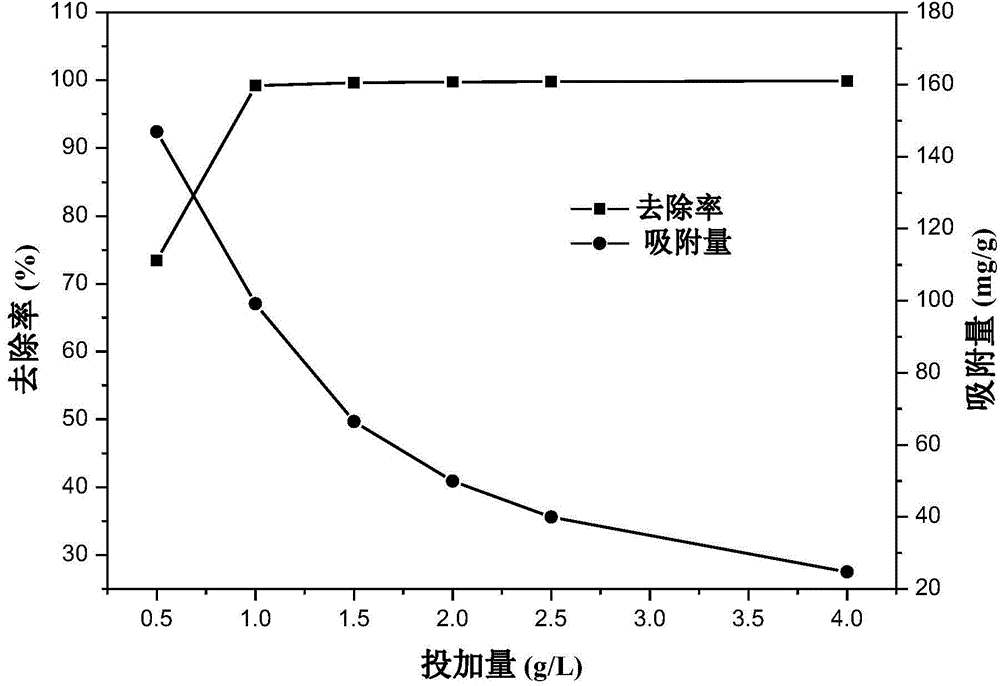

[0034] Take 8 parts of methylene blue solution with an initial concentration of 100mg / L, and in each part according to the concentration of 500mg / L, 1000mg / L, 1500mg / L, 2000mg / L, 2500mg / L, 3000mg / L, 3500mg / L and 4000mg / L respectively Dosage Add the magnetic graphene oxide prepared in Example 1, and adjust the pH value of each solution to be greater than 5, and oscillate and absorb in a constant temperature oscillator at 30°C, the oscillating speed is 150 rpm, and the oscillating time is 6 hours . After the shaking is completed, magnetic separation is carried out under the condition of an external magnetic field, the concentration of methylene blue in the supernatant is measured, and the removal effect is analyzed. Such as image 3 As shown, when the dosage is greater than 1000mg / L, the removal rate is above 99%; as the dosage increases, the saturated adsorption capacity gradually decreases.

Embodiment 3

[0036] Take 12 parts of methylene blue solution with an initial concentration of 100mg / L, adjust the pH values to 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 and 14, and add 1000mg / L The magnetic graphene oxide prepared in Example 1 was added in a large amount, and the adsorption was oscillated in a constant temperature oscillator at 30° C., the oscillating speed was 150 rpm, and the oscillating time was 6 hours. After shaking, perform magnetic separation, measure the concentration of methylene blue in the supernatant, and analyze the removal effect. Such as Figure 4 As shown, when the pH value is greater than 5, the removal rate is above 90%, and the pH value decreases after the adsorption is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com