Semiconductor structures and methods of forming them

A semiconductor and formation layer technology, which is applied in semiconductor/solid-state device manufacturing, grinding machine tools, manufacturing tools, etc., can solve the problems that the electrical properties of semiconductor structures need to be improved, and achieve the effects of improving grinding quality, corrosion, and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

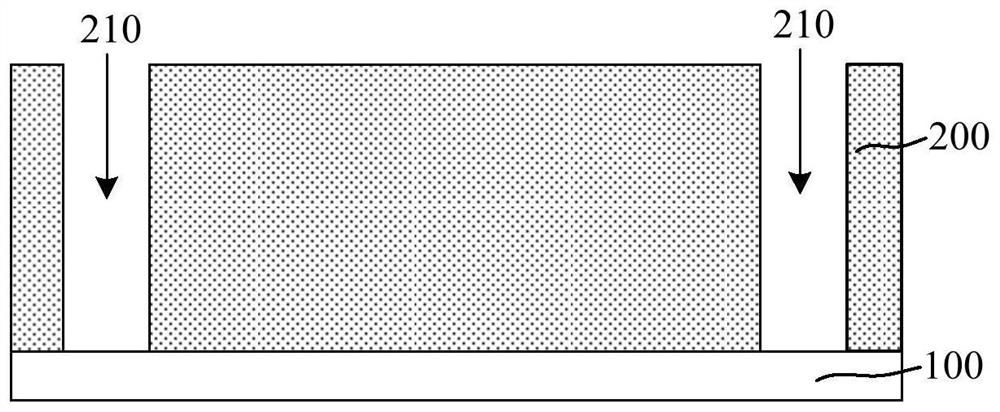

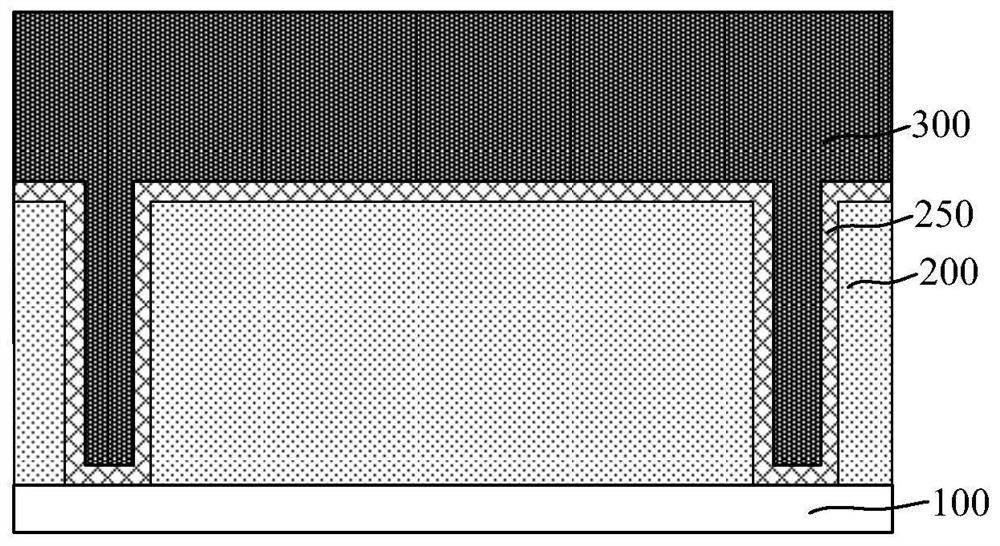

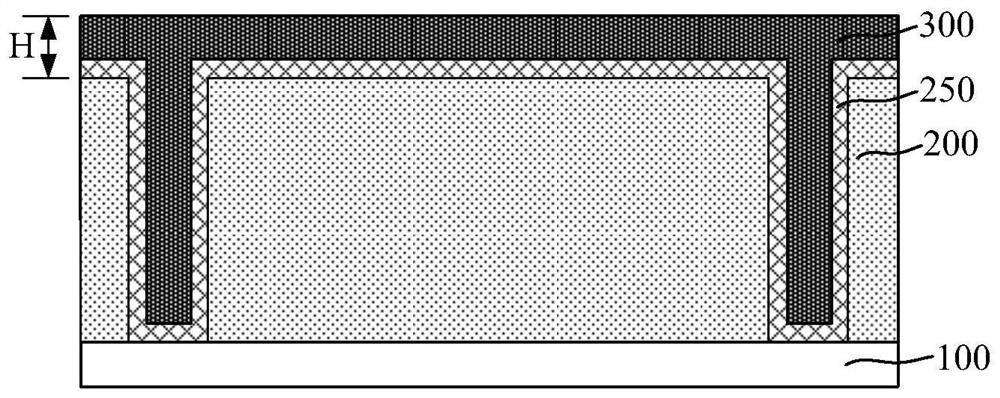

[0031] It can be seen from the background art that even if the contact hole plug is made of a material with a lower resistance value, the electrical performance of the semiconductor structure still needs to be improved. Analysis performance still needs to be improved because:

[0032] Since the cobalt material has a small resistance value and a good filling performance (Gap Filling), currently in the field of semiconductor manufacturing, the commonly used material for the contact hole plug (CT) is cobalt, which is beneficial to reduce the RC delay.

[0033] When a chemical and mechanical polishing (CMP) process is used to planarize the cobalt layer, the solution used in the cleaning operation and the transmission operation in the chemical mechanical polishing process is deionized water (DIW). The material is prone to corrosion (Corrosion) when exposed to deionized water; in addition, when the chemical mechanical polishing process uses an acidic grinding liquid, the acidic grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com