Preparation method of packaging bag capable of being quickly degraded

A rapid degradation and packaging bag technology, applied in the field of packaging bags, can solve the problems of unreasonable use of plastic bags, long decomposition cycle, white pollution, etc., and achieve the effect of shortening the decomposition cycle, improving degradation efficiency, and improving the effect of diffuse reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

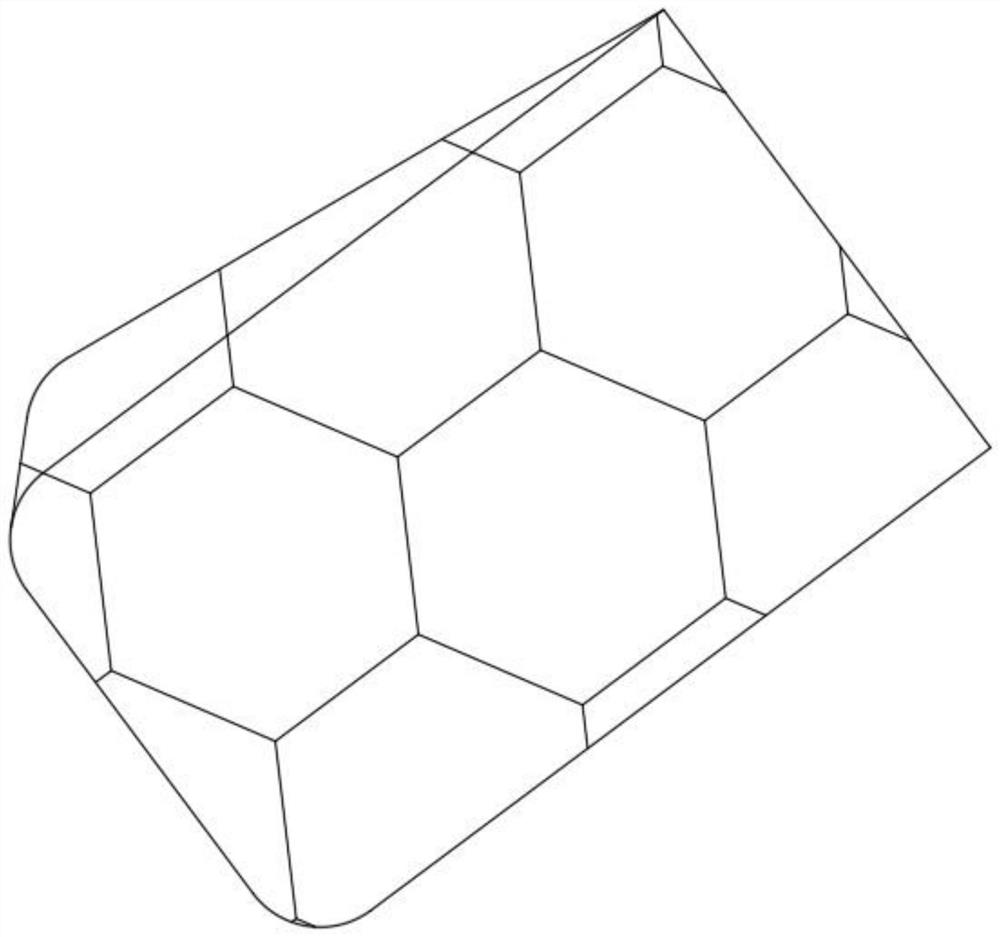

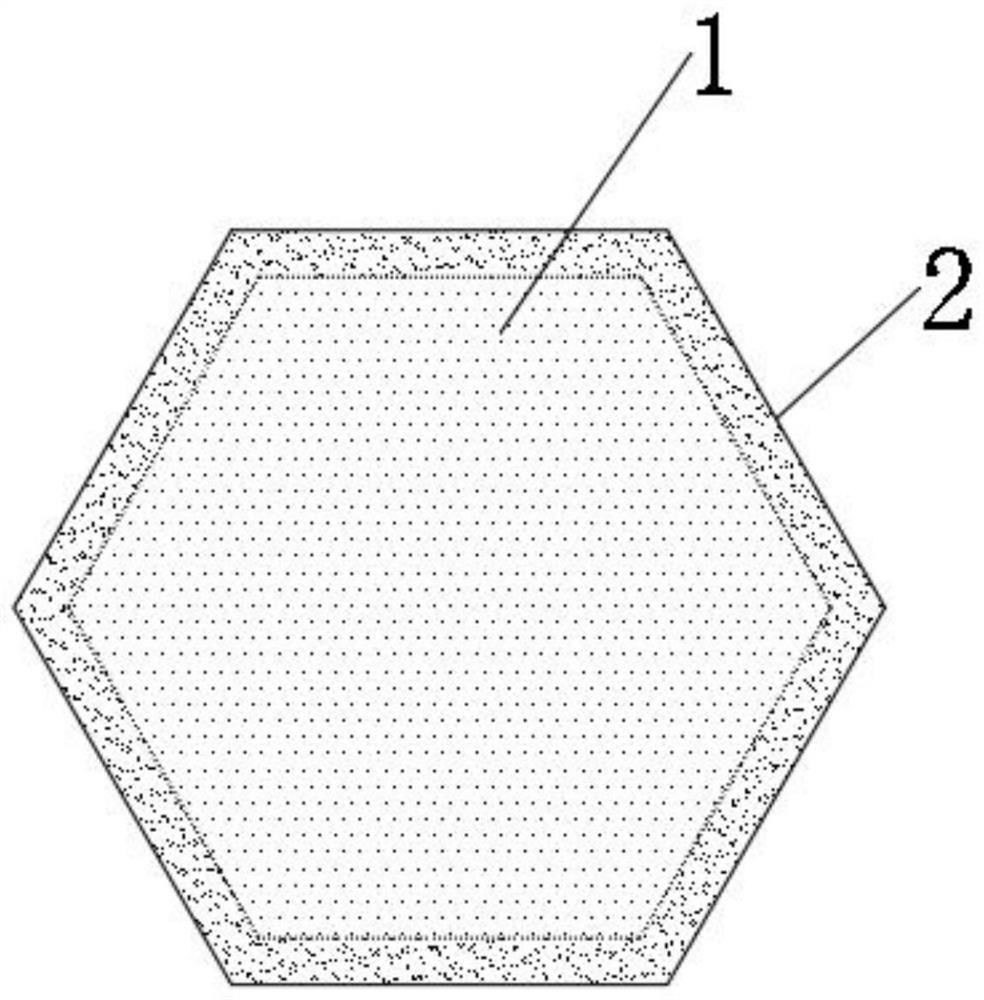

[0041] see figure 1 , a method for preparing a rapidly degradable packaging bag, comprising the following steps:

[0042] S1. Weigh 60 parts of starch, 10 parts of glycerin, 10 parts of organic polymer, 0.5 part of dispersant, 4 parts of toughening agent, 0.5 part of photodegradant and 8 parts of filler in parts by weight and uniformly mix to obtain a mixture;

[0043] S2. Add the mixture into a twin-screw extruder, and melt and extrude to pelletize at a screw speed of 100r / min and a temperature of 175°C;

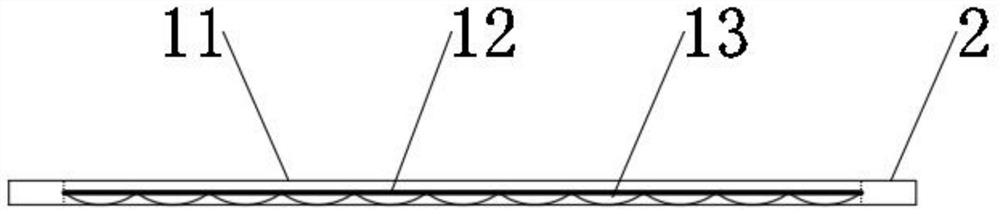

[0044] S3, then film forming is performed at a processing temperature of 175°C by casting method or extrusion method, and the film is evenly covered with degradable scales during the film forming process, and is combined with the film after cooling and forming;

[0045] S4. Finally, take the processed film to make bags, cut, heat seal, print and pack.

[0046] The starch is at least one of rice starch, corn starch, mung bean starch, lotus root starch and potato starch.

...

Embodiment 2

[0057] A method for preparing a rapidly degradable packaging bag, comprising the following steps:

[0058] S1. Weigh 70 parts of starch, 12 parts of glycerin, 15 parts of organic polymer, 0.8 parts of dispersant, 5 parts of toughening agent, 0.8 part of photodegradant and 12 parts of filler in parts by weight and mix uniformly to obtain a mixture;

[0059] S2. Add the mixture into a twin-screw extruder, and melt-extrude and granulate at a screw speed of 150r / min and a temperature of 180°C;

[0060] S3, and then form a film at a processing temperature of 180°C by casting or extrusion. During the film forming process, it is evenly covered with degradable scales, and is combined with the film after cooling and forming;

[0061] S4. Finally, take the processed film to make bags, cut, heat seal, print and pack.

[0062] The rest are consistent with Example 1.

Embodiment 3

[0064] A method for preparing a rapidly degradable packaging bag, comprising the following steps:

[0065] S1. Weigh 80 parts of starch, 15 parts of glycerin, 20 parts of organic high molecular polymer, 1 part of dispersant, 6 parts of toughening agent, 1 part of photodegradant and 15 parts of filler in parts by weight and uniformly mix to obtain a mixture;

[0066] S2. Add the mixture into a twin-screw extruder, and melt-extrude and granulate at a screw speed of 200r / min and a temperature of 190°C;

[0067] S3, then film forming is performed at a processing temperature of 190°C by casting method or extrusion method, and the film is evenly covered with degradable scales during the film forming process, and is combined with the film after cooling and forming;

[0068] S4. Finally, take the processed film to make bags, cut, heat seal, print and pack.

[0069] The rest are consistent with Example 1.

[0070] see Figure 5 , the present invention can improve the raw material fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com