Method for producing high-quality steel through abandoned cast steel bricks

A high-quality, steel brick technology, applied in the manufacture of converters, etc., can solve the problems of long production cycle, non-circulation, high cost, etc., and achieve the effect of long production cycle, low oxidation and high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

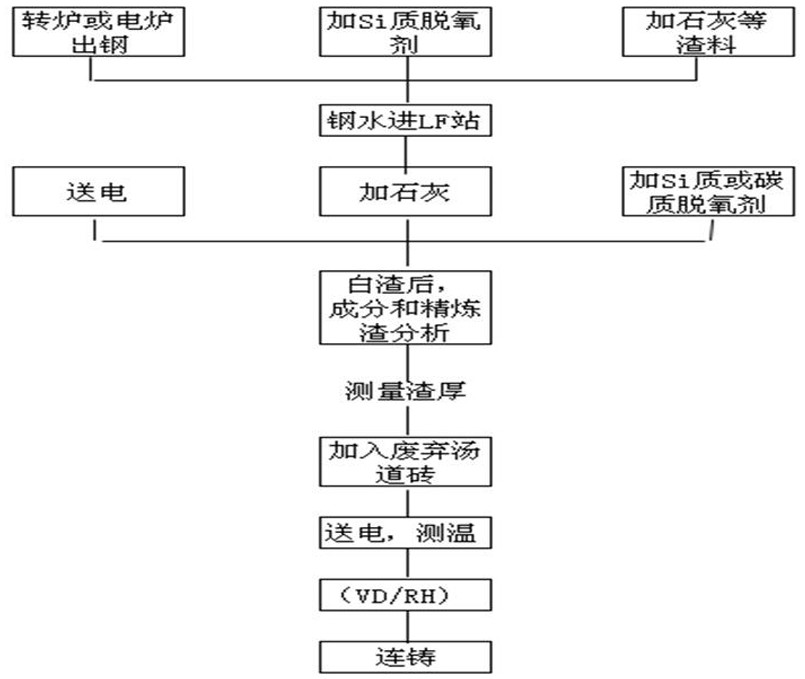

[0040] Taking the production of spring steel 55SiCrV as an example, it is produced in a converter (or electric furnace).

[0041] Converter tapping composition: [C]≥0.06%, [P]≤0.012%; tapping temperature: 1630~1670°C; red-packet slag-free tapping;

[0042] Materials added during tapping: recarburizer, ferrosilicon manganese (or ferrosilicon, ferromanganese), other alloys, lime;

[0043] Temperature measurement, sampling.

[0044] LF furnace:

[0045] After the ladle arrives at the station, power is sent, and silicon and carbon deoxidizers are used for deoxidation. According to the analysis results after the converter, add to the specified range. After the temperature is ≥ 1520 ° C and the slag is white, power off and lift the electrode, and take component samples and slag samples for analysis. .

[0046] After the composition results come out, adjust the molten steel composition;

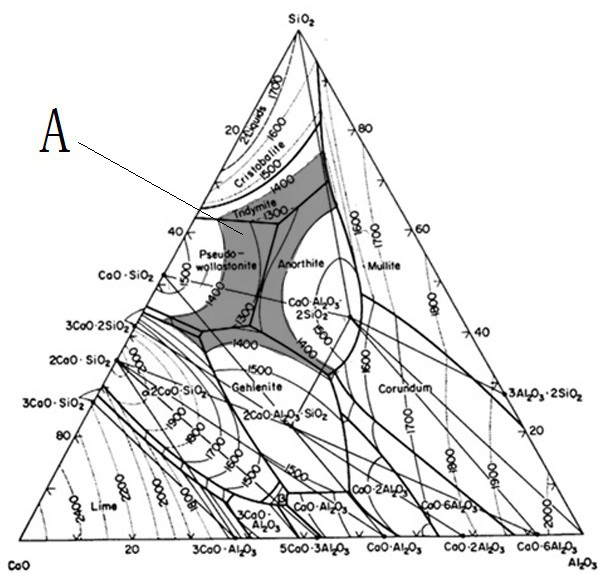

[0047] After the results of the slag sample come out, the composition of the refining slag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com