Continuous oxidation treatment system and method

A technology of oxidation treatment and oxidation tank, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of low production efficiency and high power consumption, and achieve the effects of improving production efficiency, reducing power consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

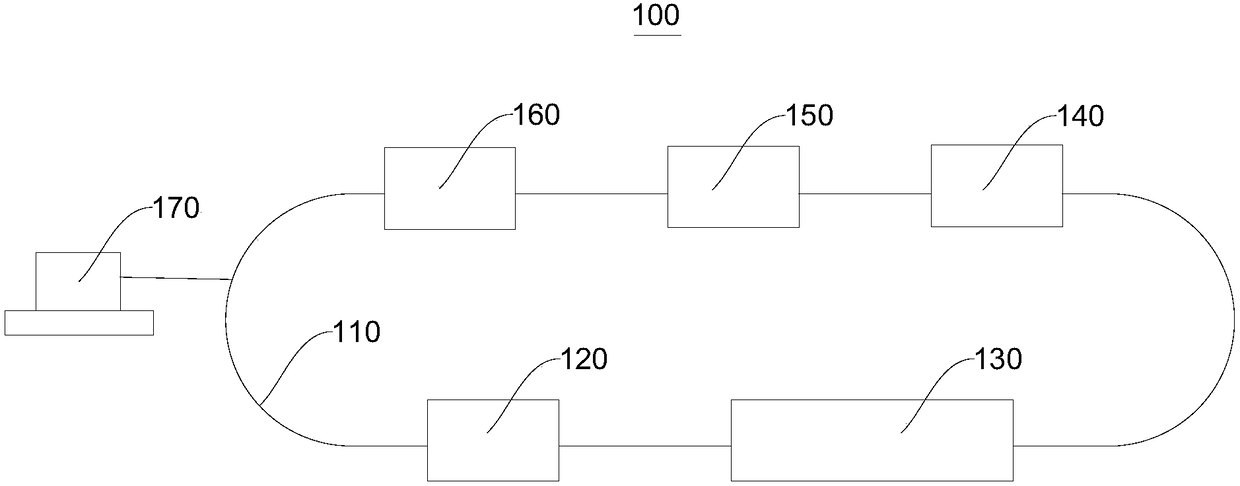

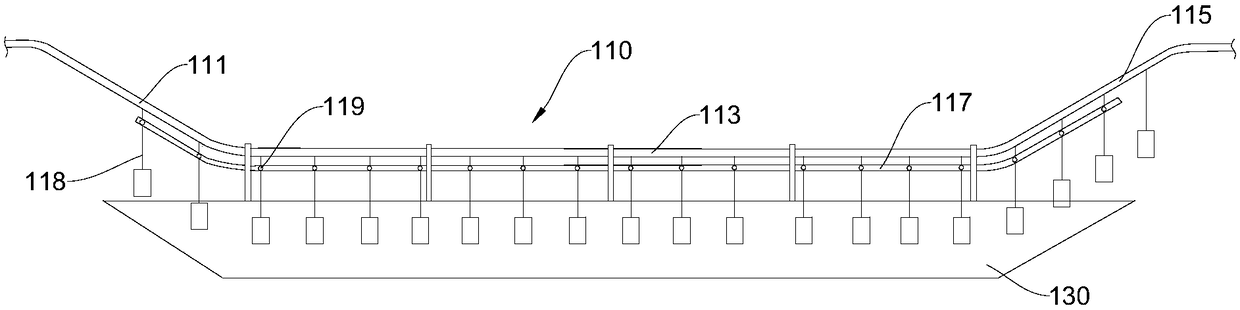

[0034] The current micro-arc oxidation treatment is intermittent, and steps such as cleaning and oxidation are performed separately, resulting in low production efficiency and high energy consumption. Please refer to figure 1 , the present embodiment provides a continuous oxidation treatment system 100, including a conveying device 110, a cleaning tank 120, an oxidation tank 130, a spray tank 140, a immersion tank 150, and a closed tank 160, the cleaning tank 120, the oxidation tank 130, the spray The box 140 , the dipping tank 150 and the closed tank 160 are arranged in sequence, and the conveying device 110 is arranged on the top of the cleaning tank 120 , the oxidation tank 130 , the spray tank 140 , the dipping tank 150 and the closed tank 160 . The conveying device 110 is used to convey the parts, so that the parts are continuously cleaned, oxidized, sprayed, soaked and sealed. This process is continuous and uninterrupted, reducing multiple operations on the parts, saving...

Embodiment 2

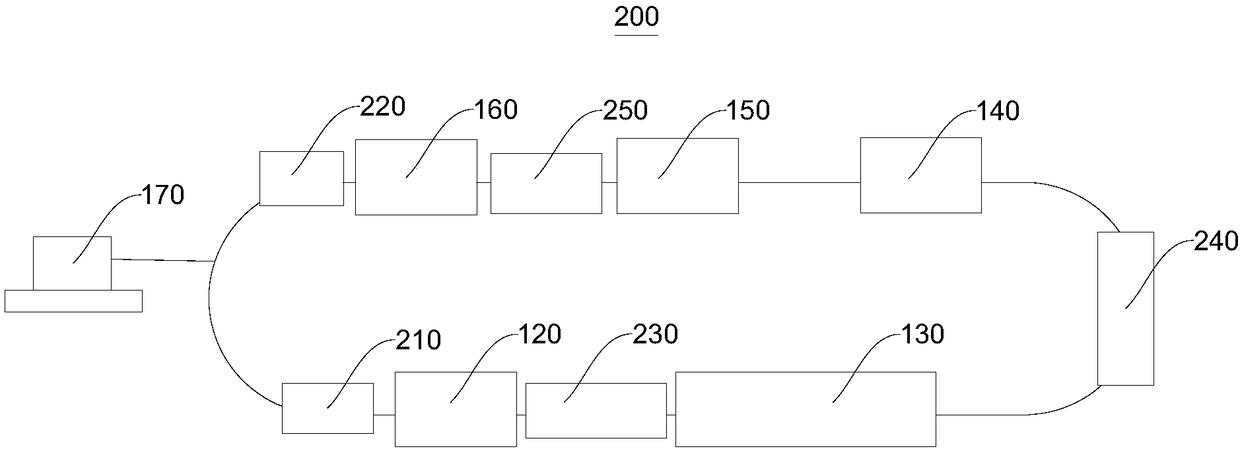

[0043] Please refer to image 3 , this embodiment provides a continuous oxidation treatment system 200 .

[0044] The difference between the continuous oxidation treatment system 200 and the continuous oxidation treatment system 100 mainly lies in:

[0045] The continuous oxidation treatment system 200 also includes a feeding area 210, a feeding area 220, a first draining area 230, a second draining area 240, and a third draining area 250. The feeding area 210 is arranged on a side of the cleaning tank 120 away from the oxidation tank 130. side, the unloading zone 220 is set on the side of the closed tank 160 away from the immersion tank 150, the first draining zone 230 is set between the cleaning tank 120 and the oxidation tank 130, and the second draining zone 240 is set between the oxidation tank 130 and the spraying tank 130. Between the tanks 140 , the third draining area 250 is disposed between the immersion tank 150 and the closed tank 160 . The processed parts are cl...

Embodiment 3

[0048] This embodiment provides a continuous oxidation treatment method, using a continuous oxidation treatment system 200 for oxidation treatment, including:

[0049] Set the moving speed of the conveying device 110 according to the time required for oxidation, and set the oxidation time and electrical parameters according to the material, surface area and application of the object. In the loading area 210 , the processing parts are clamped to the hanger 118 on the conveying device 110 , and the continuous oxidation treatment system 200 is started. Put the processed parts into the cleaning tank 120 and wash them for 1-2 minutes. After draining excess water in the first draining zone 230, they enter the oxidation tank 130 for oxidation for 10-30 minutes. After draining in the second draining zone 240, they enter the spray box 140 for cleaning ~ 2 minutes, then enter the immersion tank 150 for immersion for 1 ~ 2 minutes, drain the excess water in the third draining area 250, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com