Method and device for treating ethylene waste lye

A technology for ethylene waste lye and waste lye, which is applied in the fields of natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the clogging of the wet oxidation reactor, the insufficient treatment effect, and the harmfulness of other treatment units, etc. To ensure the gas-liquid mass transfer efficiency and oxidation effect, ensure long-term stable operation, and reduce the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]The ethylene waste alkali liquor treated in this example comes from the waste alkali liquor discharged during the alkali washing process of ethylene cracking gas in a factory, wherein the COD concentration is 35000 mg / L, S 2- The concentration is 15200mg / L, and the petroleum is 1320mg / L, including butadiene, isoprene and other substances.

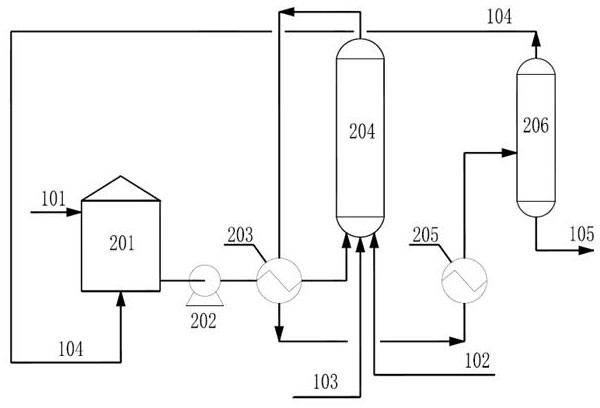

[0033] with attached figure 1 The treatment process and device shown are used for treatment, and the waste ethylene lye is transported to the air flotation tank for air flotation treatment, and the gas after gas-liquid separation in this process is used as air flotation gas to remove diolefin substances in the waste lye.

[0034] After the waste lye is treated by air flotation, it is transported to the heat exchanger by the feed pump, and exchanges heat with the material discharged from the wet oxidation reactor. After the heat exchange reaches 160 °C, it enters the wet oxidation reactor and reacts with the incoming compressed air. ,...

Embodiment 2

[0038] The ethylene waste alkali liquor treated in this example comes from the waste alkali liquor discharged during the alkali washing process of ethylene cracking gas in a factory, wherein the COD concentration is 10000 mg / L, S 2- The concentration is 3700mg / L, and the petroleum is 650mg / L, including butadiene, isoprene and other substances.

[0039] with attached figure 1 The treatment process and device shown are used for treatment, and the waste ethylene lye is transported to the air flotation tank for air flotation treatment, and the gas after gas-liquid separation in this process is used as air flotation gas to remove diolefin substances in the waste lye.

[0040] After the waste lye is treated by air flotation, it is transported to the heat exchanger by the feed pump, and exchanges heat with the material discharged from the wet oxidation reactor. After the heat exchange reaches 120 °C, it enters the wet oxidation reactor and reacts with the incoming compressed air. , ...

Embodiment 3

[0044] The ethylene waste alkali liquor treated in this example comes from the waste alkali liquor discharged during the alkaline washing process of ethylene cracking gas in a factory, wherein the COD concentration is 50000 mg / L, S 2- The concentration is 22000mg / L, and the petroleum is 1530mg / L, including butadiene, isoprene and other substances.

[0045] with attached figure 1 The treatment process and device shown are used for treatment, and the waste ethylene lye is transported to the air flotation tank for air flotation treatment, and the gas after gas-liquid separation in this process is used as air flotation gas to remove diolefin substances in the waste lye.

[0046] After the waste lye is treated by air flotation, it is transported to the heat exchanger by the feed pump, and exchanges heat with the material discharged from the wet oxidation reactor. After the heat exchange reaches 190 °C, it enters the wet oxidation reactor and reacts with the incoming compressed air....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com