A method and system for removing organic impurities in salt-making brine

An organic impurity and brine technology, applied in the field of salt chemical industry, can solve the problems of poor oxidation activity and oxidation ability, difficult to realize continuous production, etc., achieve good impurity removal effect, improve oxidation activity and oxidation ability, and improve the effect of mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

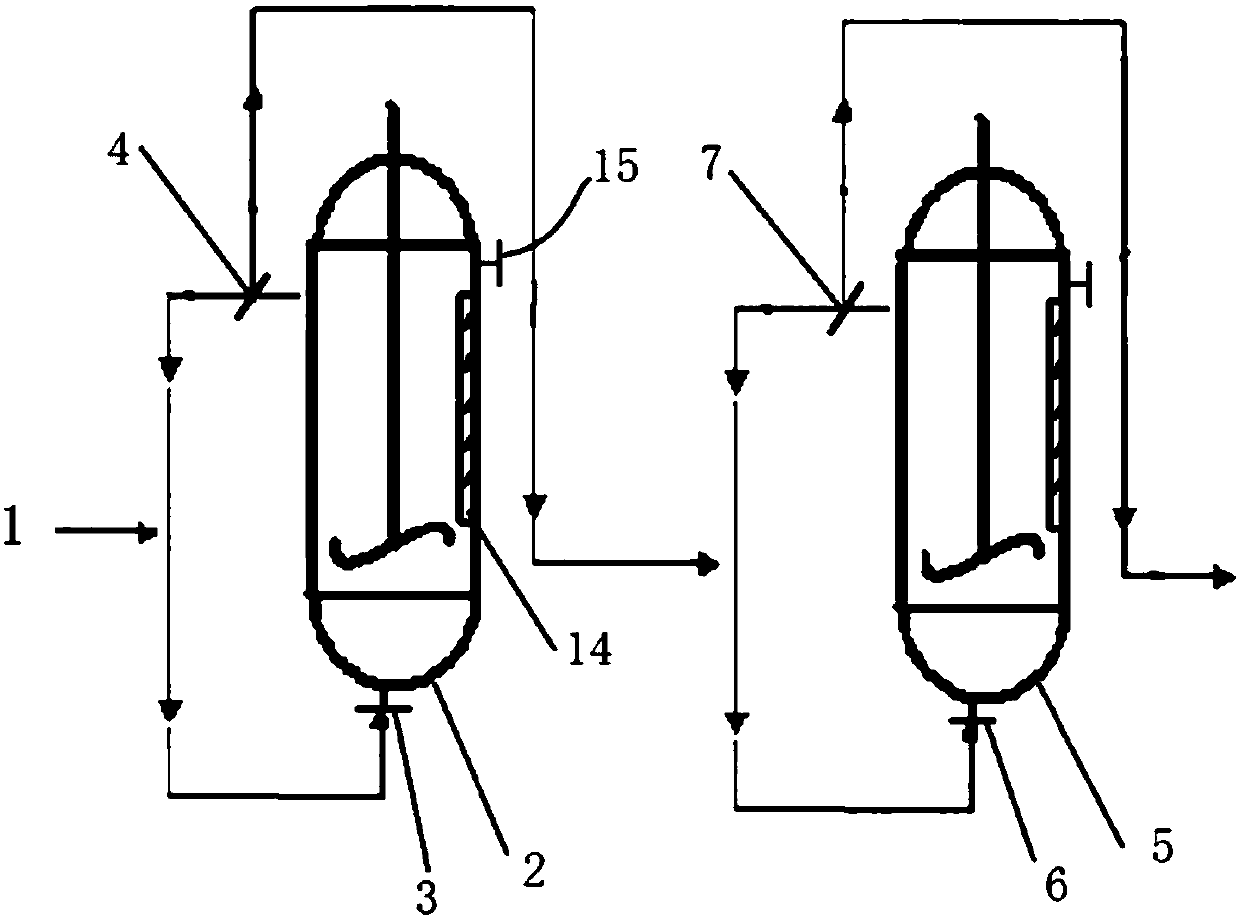

[0051] The system for removing organic impurities in salt-making brine of this embodiment, such as figure 1 As shown, it is formed in series by the first-stage reactor 2 and the second-stage reactor 5, and the discharge port 4 of the first-stage reactor is respectively connected with the feed port 3 of the current-stage reactor and the inlet of the second-stage reactor. The feed port 6 is connected to allow a part of the discharge to circulate into the primary reactor, and the other part enters the second-stage reactor; the discharge port 7 of the second-stage reactor is separated from the feed port 6 of the primary reactor. In addition to the phase connection, a discharge pipe is also connected to discharge the material out of the reaction system; the reactors at all levels are provided with feeding ports 15 for adding oxidants and catalysts, and the reactors at all levels are provided with ultraviolet lamps 14 .

[0052] When the system is in operation, the brine for salt pr...

Embodiment 2

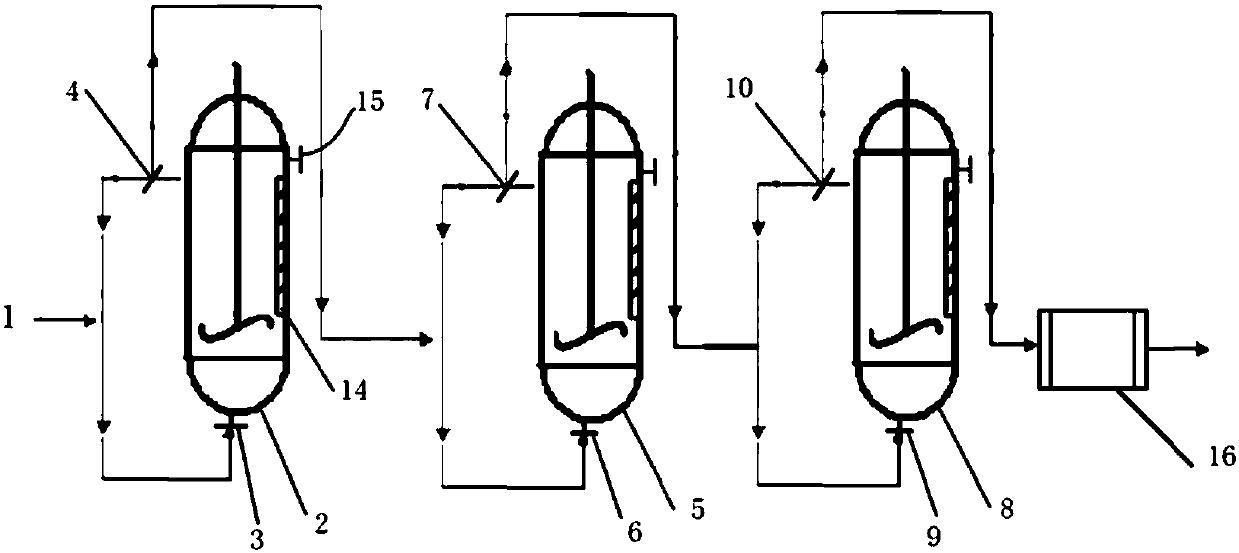

[0054] The system for removing organic impurities in salt-making brine of this embodiment, such as figure 2 As shown, it is formed in series by the first-stage reactor 2, the second-stage reactor 5 and the third-stage reactor 8, and the discharge port 4 of the first-stage reactor is connected with the feed port 3 and the The feed port 6 of the second-stage reactor is connected, and a part of the discharge is used to circulate into the current-stage reactor, and the other part enters the second-stage reactor; the discharge port 7 of the second-stage reactor is connected to the current stage respectively. The feed port 6 of the reactor is connected with the feed port 9 of the third-stage reactor; the discharge port 10 of the third-stage reactor is connected with the feed port 9 of the current reactor, and is also connected with a row The feed pipe, the discharge pipe is connected with the inlet of the filter 16 and is used to discharge the material out of the reaction system af...

Embodiment 3

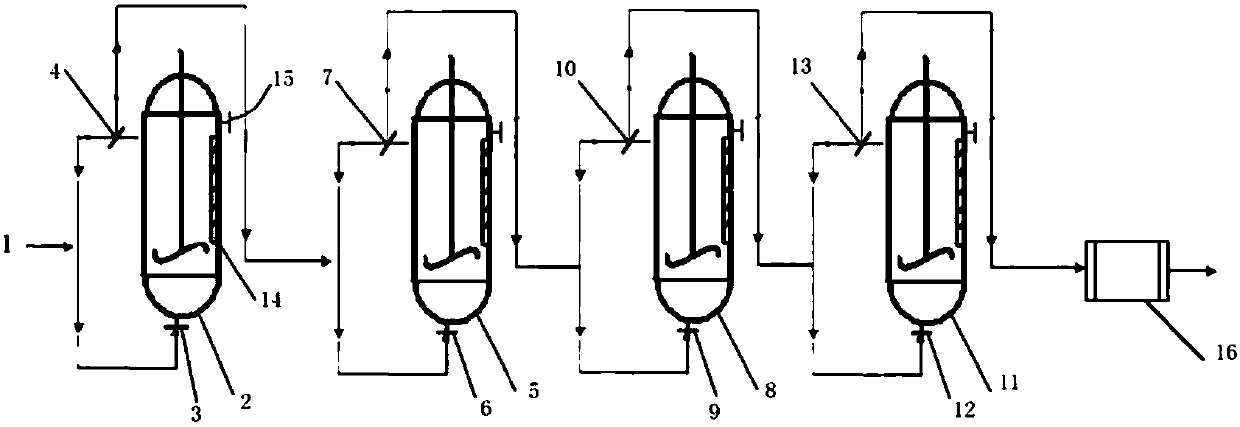

[0057] The system for removing organic impurities in salt-making brine of this embodiment, such as image 3 As shown, it is formed in series by the first-stage reactor 2, the second-stage reactor 5, the third-stage reactor 8 and the fourth-stage reactor 11, and the outlet 4 of the first-stage reactor reacts with this stage respectively. The feed port 3 of the reactor is connected with the feed port 6 of the second-stage reactor, and is used to make a part of the output circulate into the current-stage reactor, and another part enters the second-stage reactor; the outlet of the second-stage reactor Feed port 7 is connected with the feed port 6 of this stage reactor and the feed port 9 of the third stage reactor respectively; The feed port 10 of the third stage reactor is respectively connected with the feed port 9 and The feed port 12 of the fourth-stage reactor is connected; the discharge port 13 of the fourth-stage reactor is connected with the feed port 12 of the current rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com