Method for treating dye wastewater with high concentration by using technology combining ultrasound wave with enzyme

A technology for the treatment of dye wastewater and technology, which is applied in the field of industrial organic wastewater treatment, can solve the problems of decreased adsorption capacity of activated carbon, short service life of activated carbon, and reduction of dye wastewater, so as to achieve not easy loss, efficient and stable degradation effect, and good degradation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

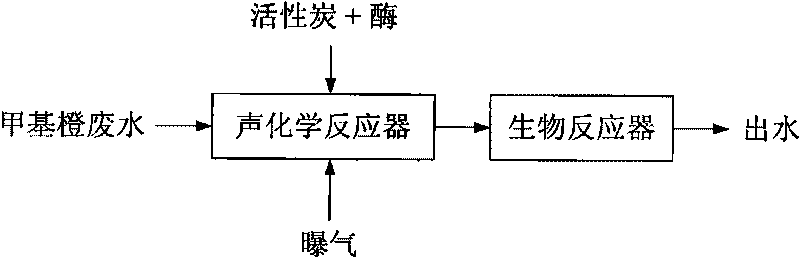

[0014] Embodiment 1: to the treatment of methyl orange wastewater

[0015] like figure 1 As shown, the COD Cr 5000ML of methyl orange wastewater with a concentration of 500mg / L is passed into the sonochemical reactor, and the treated granular activated carbon is loaded. The particle size of the activated carbon is 1.5-4.0mm. Laccase is attached to the surface and pores of the activated carbon. Activated carbon and water for aeration. The frequency of the sonochemical reactor is adjusted to 40kHz, the power is 40W, the temperature is controlled at 15-35°C, and the reaction time of the dye wastewater in the sonochemical reactor is 10min. After activated carbon adsorption, ultrasound, and laccase degradation of methyl orange wastewater, the decolorization rate reaches 70%, and the BOD 5 / COD Cr When the value is greater than 0.7, the biodegradability of wastewater is improved, which fully meets the requirements of subsequent biological treatment. Subsequent biological treatm...

Embodiment 2

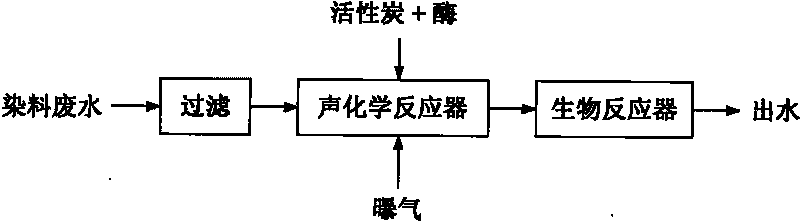

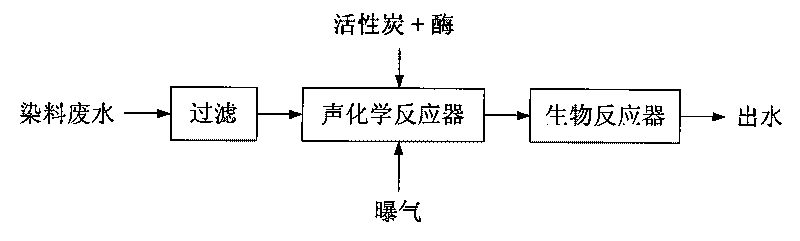

[0016] Embodiment 2: to the processing of actual dye wastewater

[0017] The main components in the actual dye wastewater are azo dyes.

[0018] like figure 2 As shown, the COD Cr 5000ML of actual dye wastewater with a concentration of 2000mg / L is passed into the sonochemical reactor after removing large suspended particles, and loaded with treated granular activated carbon. The particle size of activated carbon is 1.5-4.0mm. With laccase attached, activated carbon and water are aerated. The frequency of the sonochemical reactor is adjusted to 40kHz, the power is 40W, the temperature is controlled at 15-35°C, and the reaction time of the dye wastewater in the sonochemical reactor is 10min. The actual dye wastewater after activated carbon adsorption, ultrasonic and laccase degradation, the decolorization rate reaches 60%, BOD 5 / COD Cr When the value is greater than 0.5, the biodegradability of wastewater is improved, which fully meets the requirements of subsequent biolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com