Fabric returned material processing equipment for non-woven fabric production

A kind of processing equipment and non-woven fabric technology, which is applied in the field of knitted textiles, can solve the problems of potential safety hazards and impact on the crushing effect, and achieve the effects of full recycling, prevention of cloth residue, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

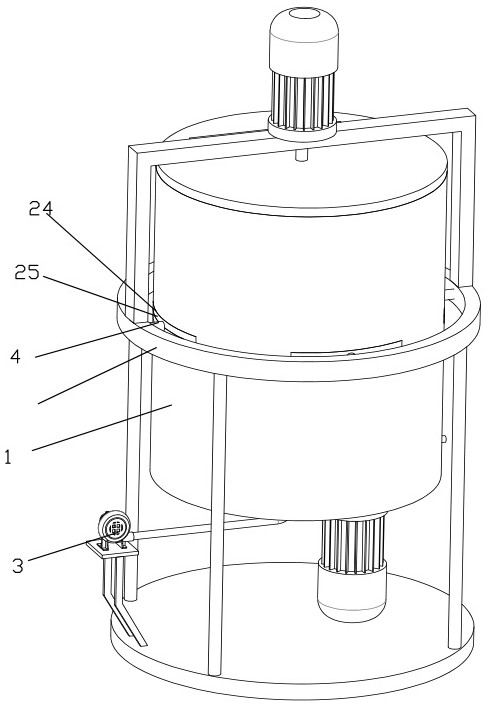

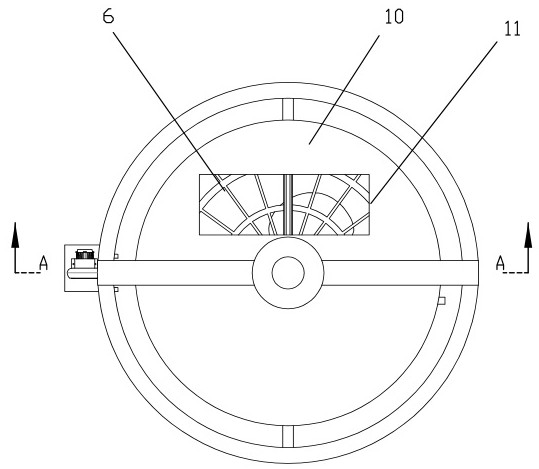

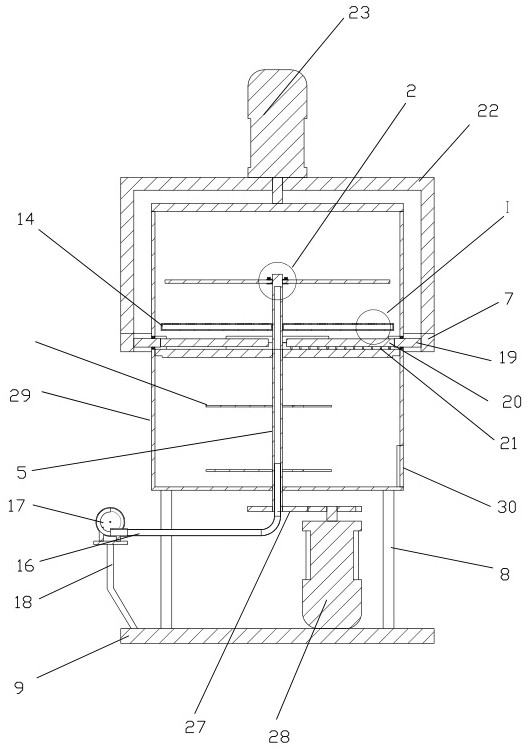

[0020] The fabric return processing equipment for non-woven fabric production according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] Such as Figure 1-5 As shown, the fabric return processing equipment for non-woven fabric production of the present invention includes a return processing cylinder 1, a cutting assembly 2, an auxiliary cutting assembly 3, and a cleaning assembly 4. The middle part of the return processing cylinder 1 is rotatably connected to a central shaft 5, and The inside of the shaft 5 is vacuum-like, the middle part of the recycling processing cylinder 1 is fixed with a circular grid 6, the central axis 5 is located at the upper end of the circular grid 6 and the cutting assembly 2 is fixed externally, and the lower end of the central shaft 5 extends out of the recycling processing cylinder 1. The extension end is internally connected to the auxiliary cutting assembly 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com