Gear with self-lubricating function

A technology of gears and functions, applied to components with teeth, gear lubrication/cooling, belts/chains/gears, etc., can solve the problems of reduced life, accelerated gear wear, loud noise, etc., to save processing costs, not easy The effect of shedding and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

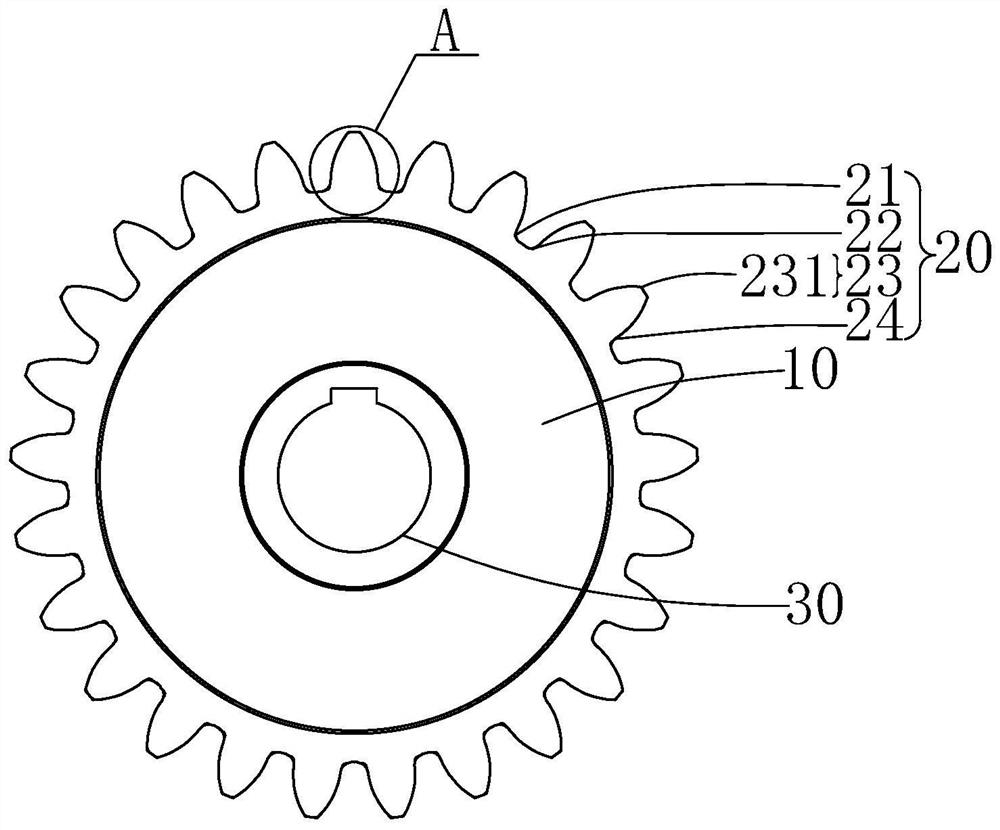

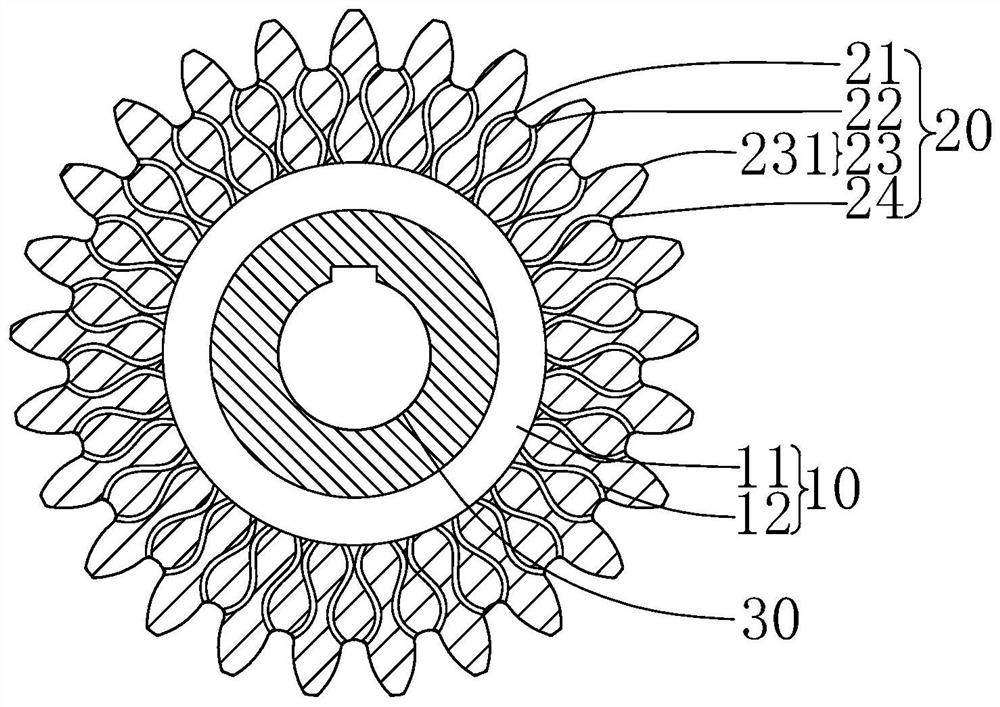

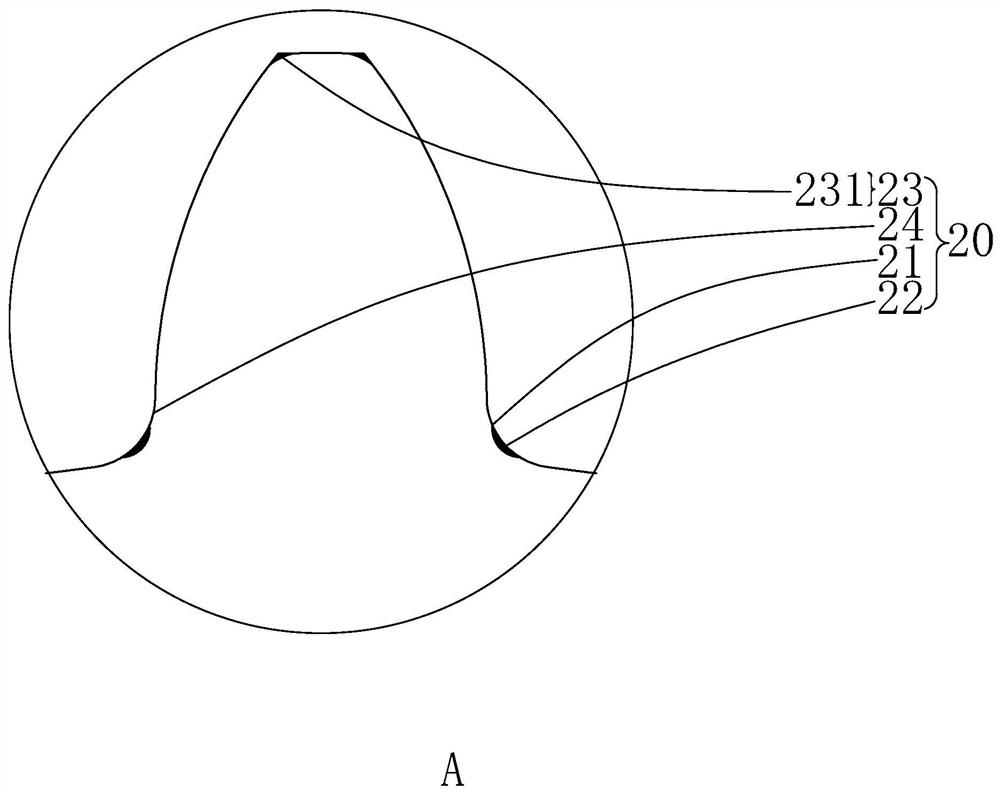

[0017] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a gear with self-lubricating function provided by the present invention. The gear with self-lubricating function includes a gear body 10, a plurality of teeth 20 arranged on the gear body 10, and a shaft hole 30, and also includes other functional modules, such as fixed buckles, etc. etc., which should be known to those skilled in the art, and will not be described in detail here.

[0018] The gear body 10 includes an oil storage chamber 11 disposed inside the gear body 10 , and a plurality of oil delivery pipes 12 communicating with the teeth 20 . The cross section of the oil storage chamber 11 is annular and coaxial with the ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com